Magnetic Disc Couplings,High Speed Flexible Disc Magnetic Shaft Couplings,Disc Type Magnetic Couplings with Bearing,Disc Type Magnetic Couplings,Pm Eddy-Current Couplings,Fds-W/Fbs-W Type Contactless Coupling

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

What are magnetic disc couplings ?

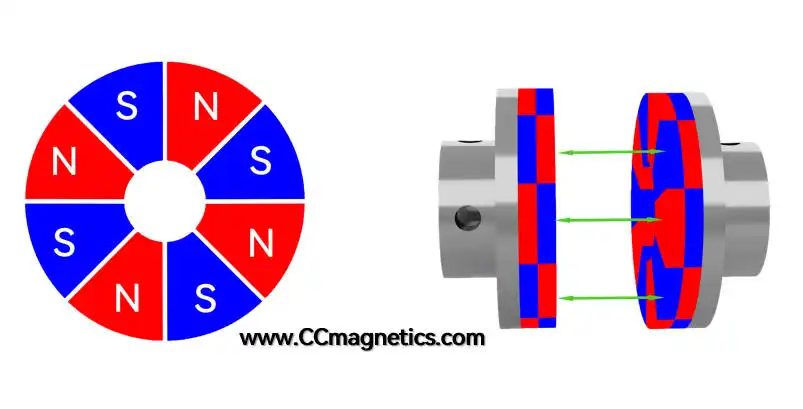

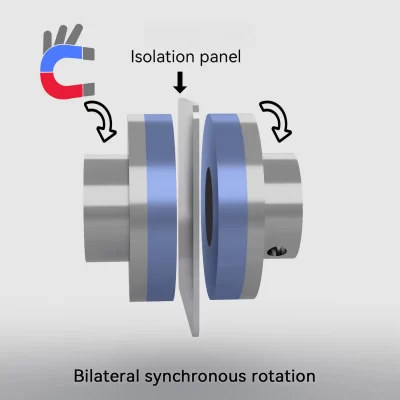

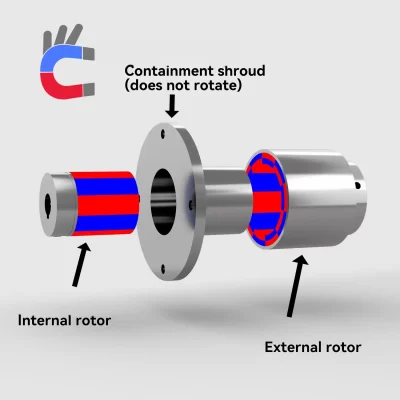

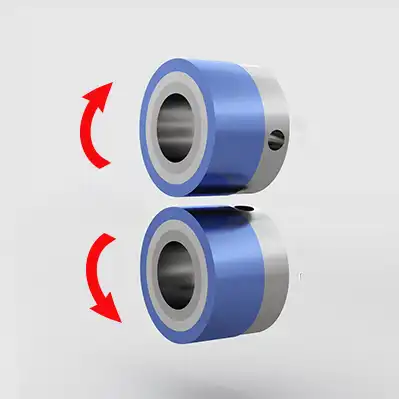

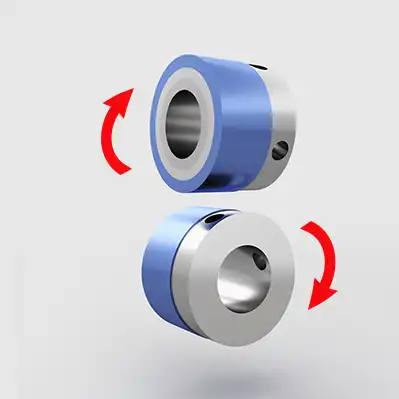

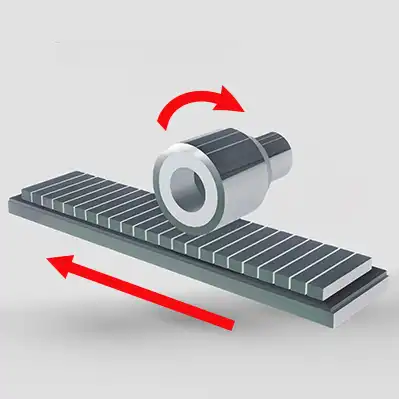

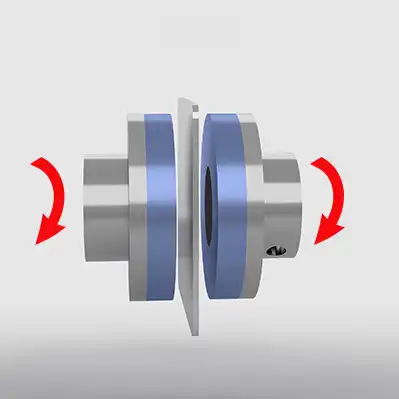

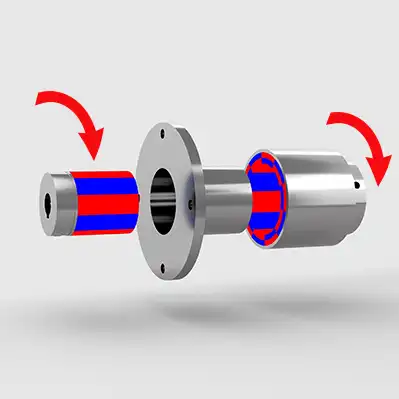

Magnetic disc couplings provide a contactless means of torque transfer. The concept is straightforward: Opposite poles attract. This fundamental principle enables the transmission of torque from one magnetic hub to another. By rotating one magnetic hub, the torque is magnetically conveyed to the companion hub. This transmission can occur through air or via a non-magnetic barrier like stainless steel or fiberglass, achieving complete isolation of the inner from the outer hub. The design excludes any contacting components.

What makes magnetic disc couplings so efficient?

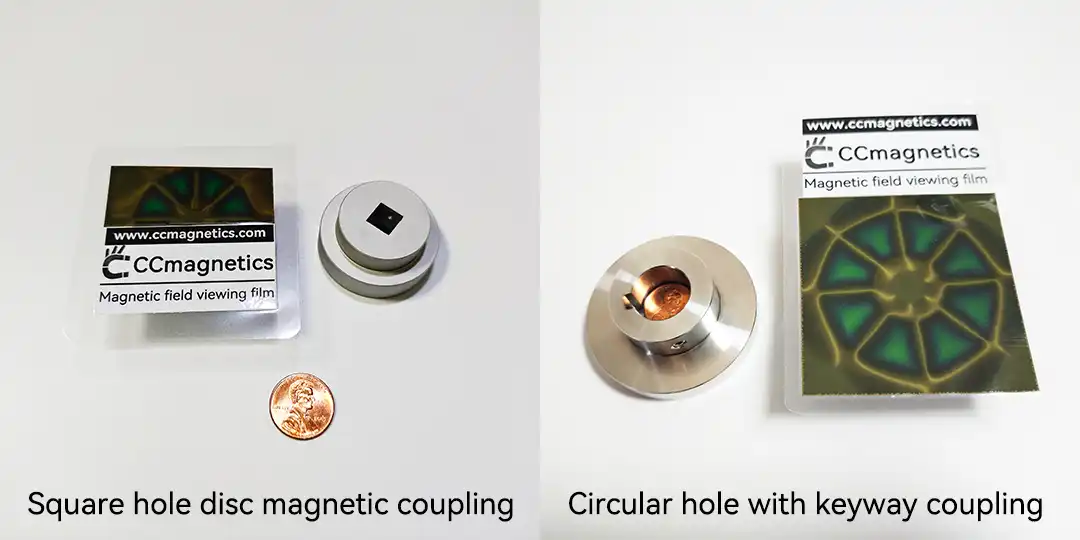

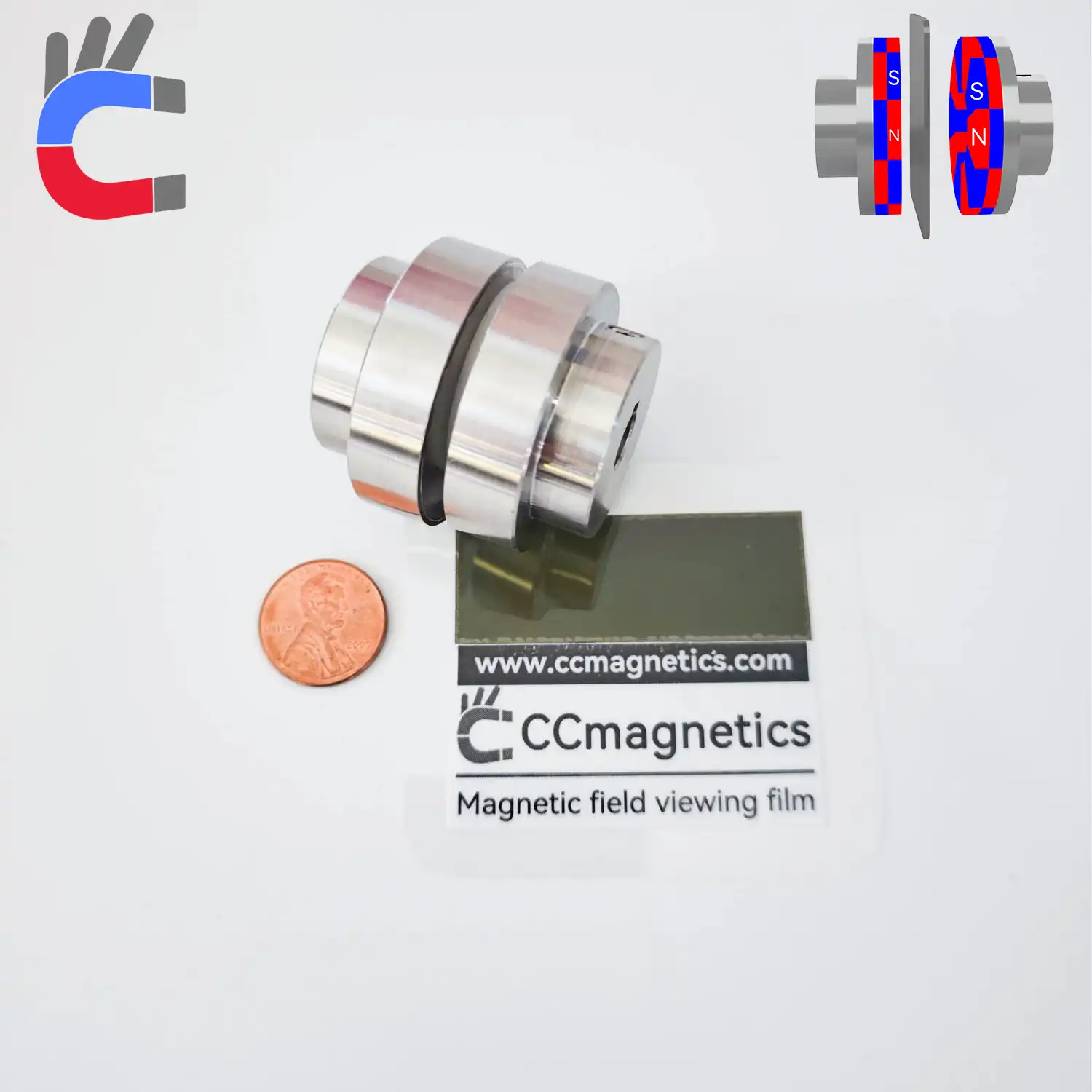

All sizes of CCmagnetics' magnetic disc couplings use sector-shaped magnets for torque transfer. These magnets maximize the use of the disc surface area, eliminating redundancy. The image above, captured using magnetic field viewing film, illustrates this point by showing the magnetic field distribution within a CCmagnetics magnetic disc coupling.

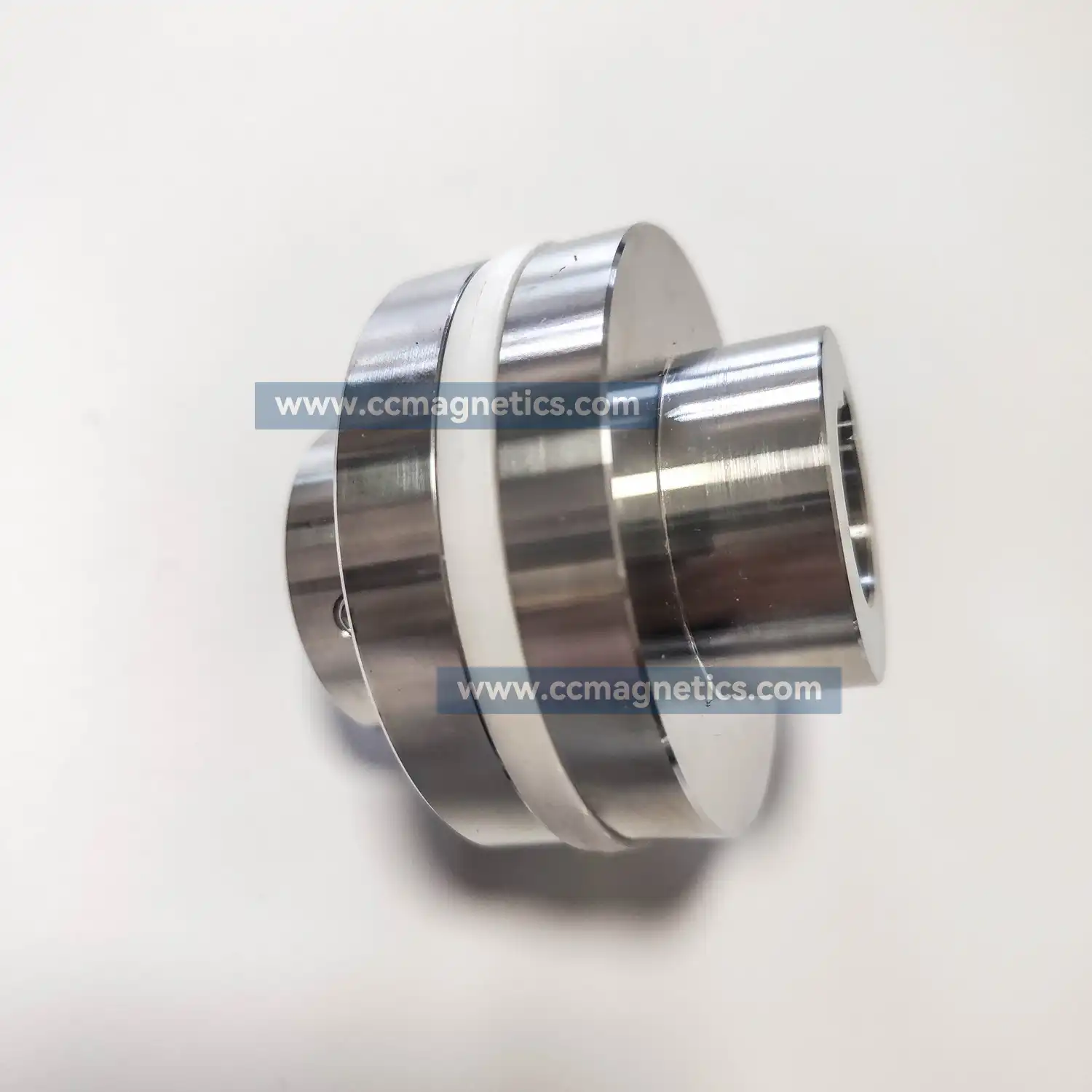

Compared to the Demo magnetic disc coupling, CCmagnetics' magnetic coupling is smaller and lighter while achieving greater torque.This disc-shaped magnetic coupling is not only more efficient but also saves valuable space within the device.

Parameter

Unit of length: millimeter.

| PN | B | SCM | SFM | MC | HS | RPM | Tq1 (N.m) | Tq5 (N.m) | A | C | D | E | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XD12 | 4~6 | S/L | A | F | B/T | 35,500 | 0.05 | - | 12 | 16 | 12 | - | M3 |

| XD24 | 6~10 | S/L/A | B/C/A | F/H | B/T | 35,000 | 0.42 | 0.04 | 24 | 18 | 18 | 10 | M4 |

| XD28 | 6~10 | S/L/A | B/C/A | F/H | B/T | 34,000 | 0.75 | 0.12 | 28 | 18 | 20 | 10 | M4 |

| XD32 | 8~12 | S/L/A | B/C/A | F/H | B/T | 32,000 | 1.95 | 0.32 | 32 | 18 | 24 | 10 | M5 |

| XD43 | 12~20 | S/L/A | B/C/A | F | B/T | 26,500 | 3.8 | 1.2 | 43 | 20 | 30 | 12 | M5 |

| XD50 | 12~20 | S/L/A | B/C/A | F | B/T | 23,000 | 4.2 | 1.5 | 50 | 22 | 34 | 13 | M5 |

| XD68 | 15~25 | S/L/A | B/C | F | B/T | 17,500 | 16.2 | 7.8 | 68 | 30 | 40 | 18 | M5 |

| XD78 | 18~30 | S/L/A | B/C | F | B/T | 15,000 | 18.5 | 10 | 78 | 32 | 42 | 18 | M5 |

| XD90 | 20~35 | S/L/A | B/C | F | B/T | 13,500 | 22.8 | 8.7 | 90 | 38 | - | 20 | M6 |

| XD100 | 20~35 | S/L/A | B/C | F | B/T | 12,000 | 28.5 | 10.5 | 100 | 40 | - | 22 | M6 |

| XD120 | 28~38 | S/L/A | B/C | F | B/T | 10,000 | 33 | 12.3 | 120 | 50 | - | 30 | M8 |

| XD130 | 35~40 | S/L/A | B/C | F | B/T | 9,000 | 50 | 19.6 | 130 | 45 | - | 25 | M8 |

| XD38 | 8~15 | S/L/A | B/C/A | F/H | B/T | 30,000 | 2.98 | 0.82 | 38 | 18 | 28 | 10 | M5 |

| XD63 | 15~25 | S/L/A | B/C | F | B/T | 20,000 | 11 | 4.5 | 63 | 25 | 36 | 15 | M5 |

Parameter Notes:

| Term | Explanation | Notes |

|---|---|---|

| SCM | Surface Covering Material | A=Aluminum 6061 Alloy (UNS A96061), |

| S=Stainless Steel 304 (UNS S30400), | ||

| L=Stainless Steel 316 (UNS S31600), | ||

| T=TC4 Titanium Alloy, Ti-6Al-4V, (UNS R56400). | ||

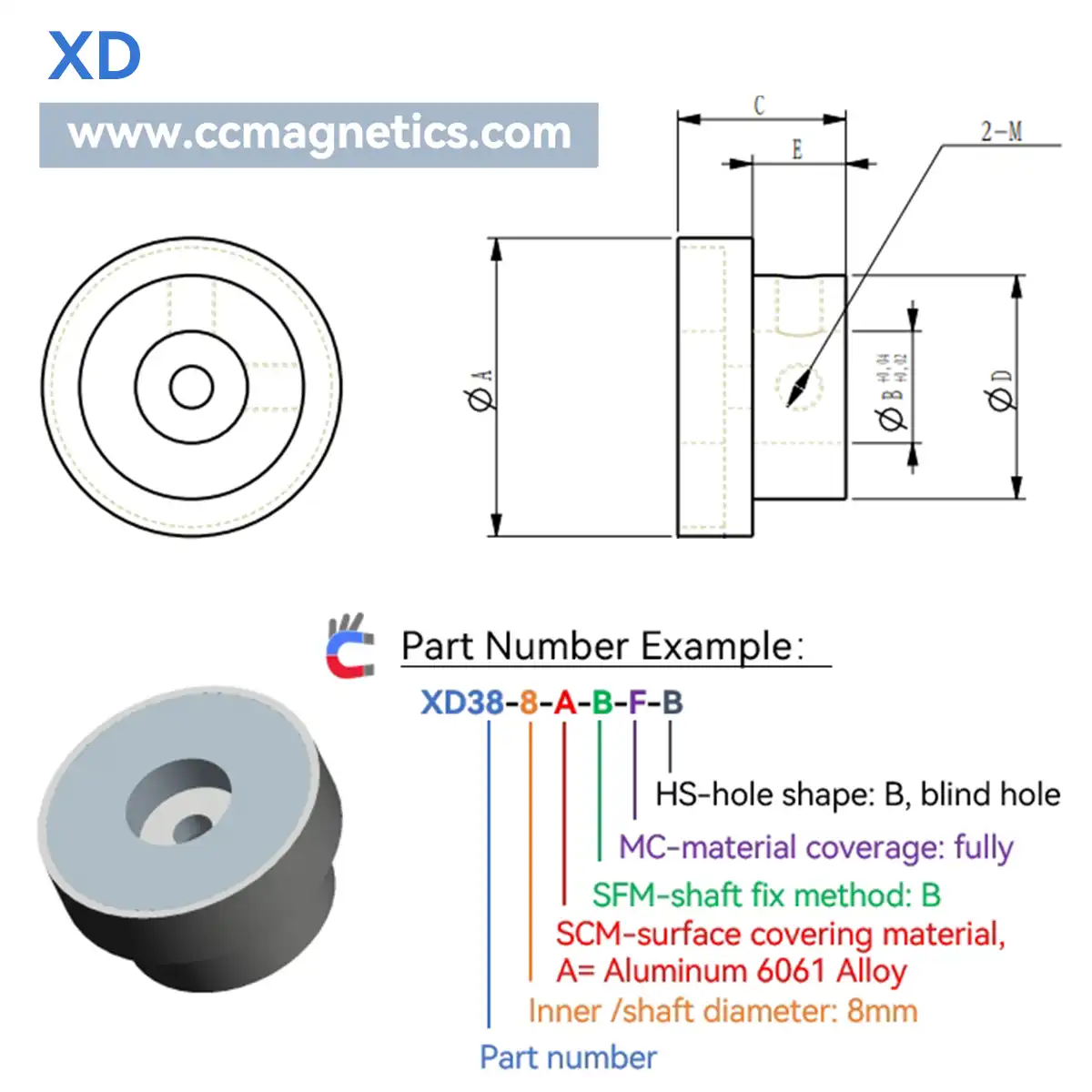

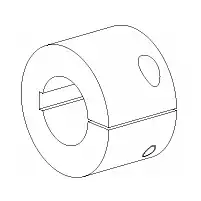

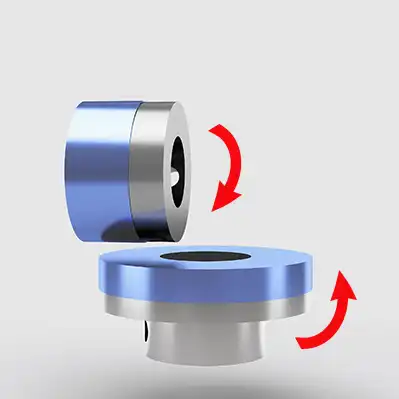

| SFM | Shaft Fixing Method | A,B,C, refer to the picture for details. |

| MC | Material Coverage | F= Fully, H= Half |

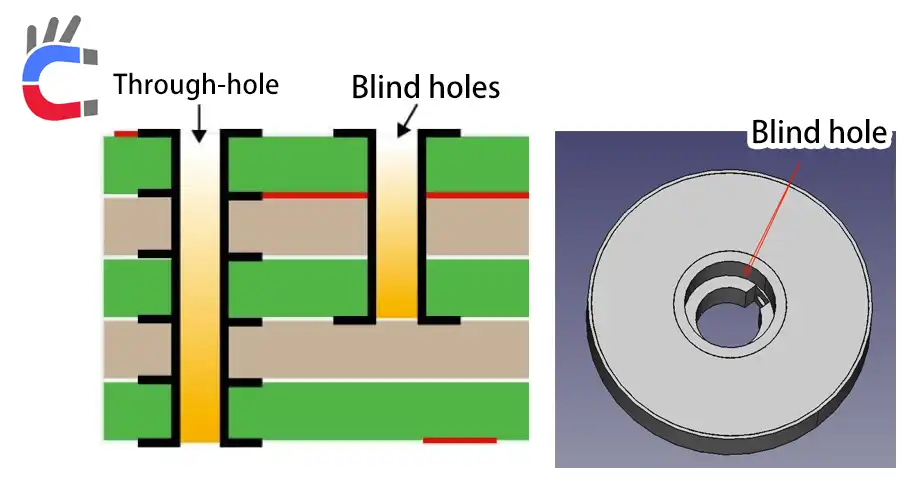

| HS | Hole Shape | B= Blind hole, T=Through hole |

| RPM | RPM, Revolutions Per Minute | Max speed, Revolutions Per Minute |

| Tq1 | Torque, gap = 1mm / 0.03in | The torque value shown is for a 1mm or 0.03in gap. |

| Tq5 | Torque, gap = 5mm / 0.2in | The torque value shown is for a 1mm or 0.03in gap. |

Shaft fixing method

Customizable Items

1. No MOQ and Global Door-to-Door Delivery

We offer global door-to-door delivery service with no minimum order quantity (MOQ).

2. Shaft Diameter and Shape (Free Service)

You can choose the shaft's size and shape to meet your specific needs.

3. Blind Holes and Through Holes (Free Service)

You can choose between blind holes and through holes as needed.

4. Half-Enclosed and Fully-Enclosed Designs (Paid Service)

You can choose between half-enclosed and fully-enclosed designs. Half-enclosed designs are less expensive but are not waterproof, while fully-enclosed designs are waterproof.

5. Material Selection (Paid Service)

You can choose the material for your magnetic disc coupling, including surface and magnet materials. Different materials are suitable for various applications. Learn more about materials used in disc-type magnetic couplings, or describe your butterfly coupling's working environment, and our staff will recommend the appropriate material.

Magnetic disc vs co-axial coupling comparison

| Magnetic disc vs co-Axial coupling comparison |

|

|

|---|---|---|

| Coupling style | Magnetic disc couplings ( XD ) | Co-axial magnetic couplings ( XC ) |

| Permanent-magnetic | √ | √ |

| Contactless | √ | √ |

| Maintenance-free | √ | √ |

| Torsionally flexible | √ | √ |

| Low vibrations | √ | √ |

| Material | Standard: SS304. Options: Aluminum alloy 6061, Stainless steel 316L, PVC, available) |

Standard: SS304. Options: SS316/UNS S31603. |

| Containment shroud | None | Optional |

| Axial forces | High axial force which must be restrained | Coupling finds its own center with ~0 axial force |

| Shaft fixing method | Small size type A, big size type B & C available |

Type B |

| Slip torque adjustment | Air gap can be adjusted to increase or decrease slip torque |

Coupling hubs can be seperated axially to decrease slip torque (axial force will result) |

| Angular misalignment capacity | 3° Max | Ensure coupling hubs (or barrier if used) do not contact |

| Parallel misalignment capacity | 6.35mm (0.25in) Max | Ensure coupling hubs (or barrier if used) do not contact |

| Containment barrier | Simple flat barrier | Top-hat shaped barrier |

| Max. pressure resistance [bar] | Up to 80 bars depending on size | Up to 90 bars depending on size |

| Max. temperature resistance [°C] | 150/300 depending on magnet material | 150/300 depending on magnet material |

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

alan.freitag –

Good quailty.It can transmit without any issue during coupling even if there is a bulkhead between them, as long as the bulkhead is made of non-magnetic material.

fergus.ryan7 –

Simple process and great customer service.

It can be used for mixing applications without needing to machine holes, sealing.