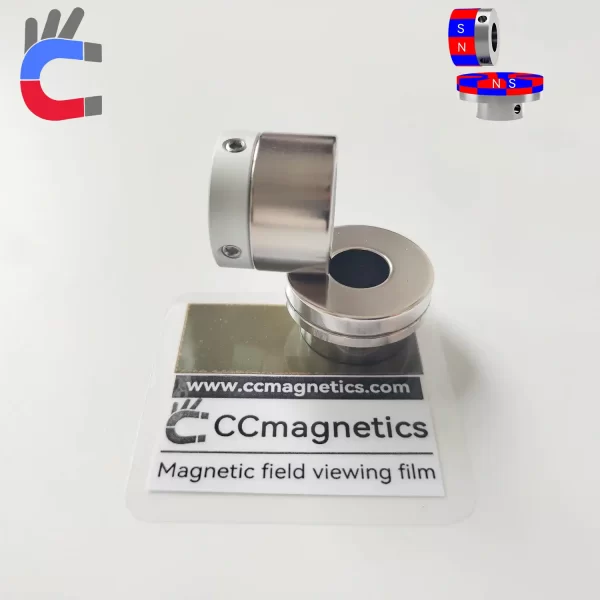

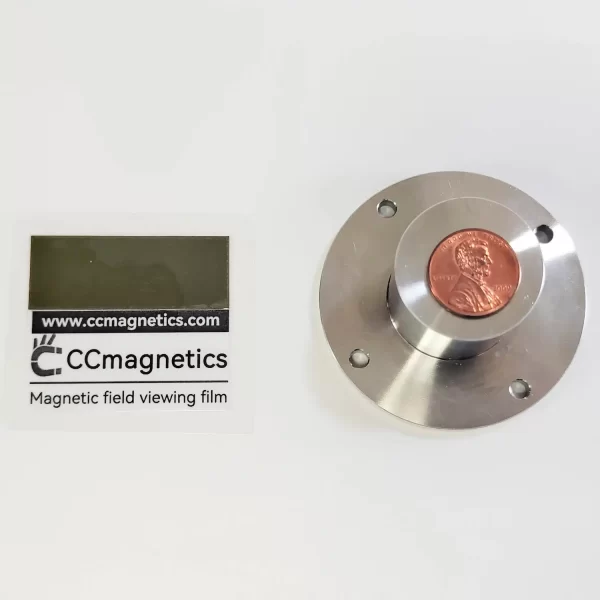

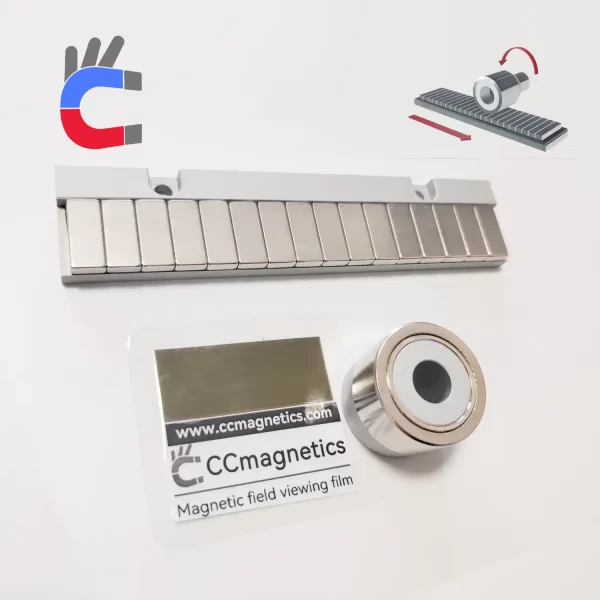

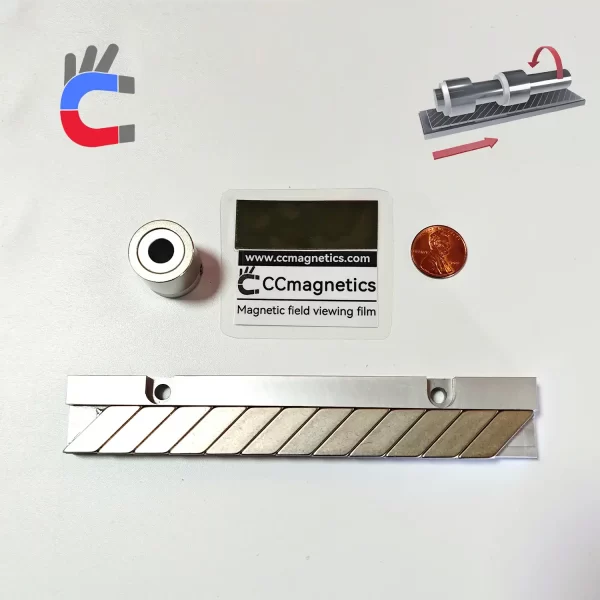

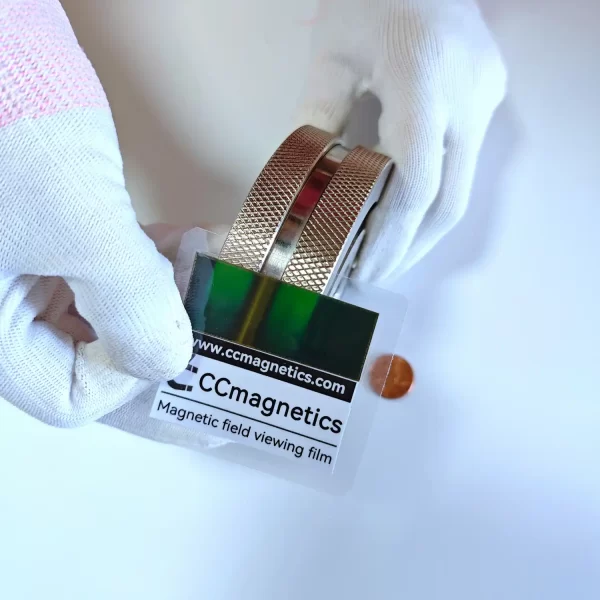

Non-Contact Magnetic Transmission Products

Non-contact transmission components utilize magnetic forces to transmit motion without physical contact. This is achieved by harnessing the attractive and repulsive forces generated by a strong magnet, resulting in smooth rotation.

Safer

torque overload protection, angle offset compatible.

Environmentally

no noise, free oil.

Maintenance-free

no friction, non-contact.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語