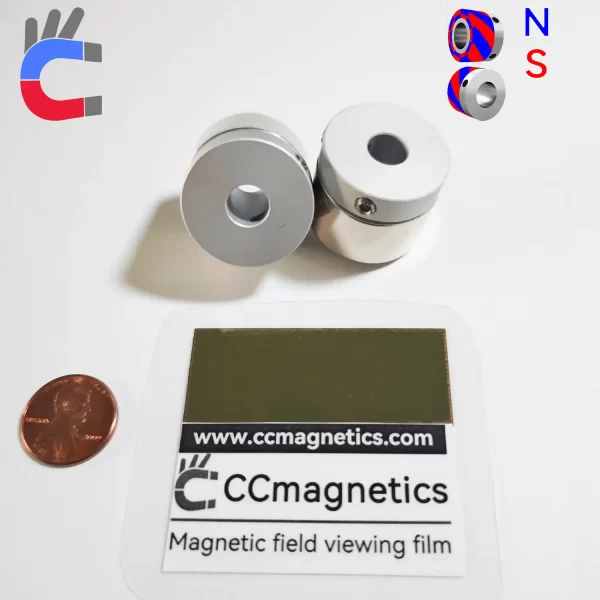

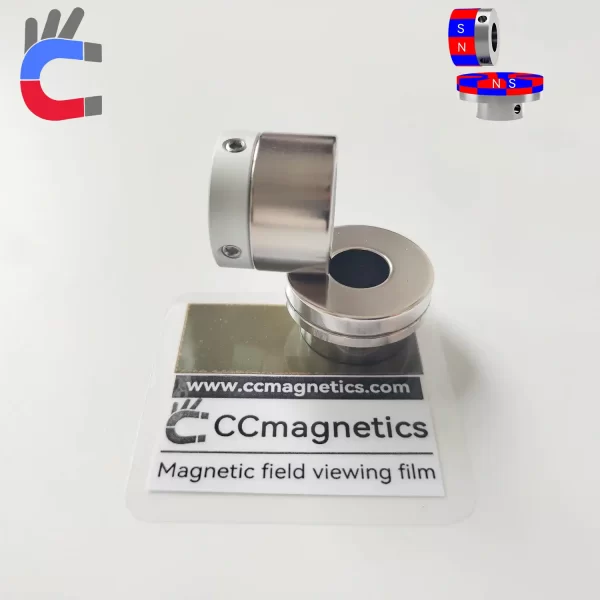

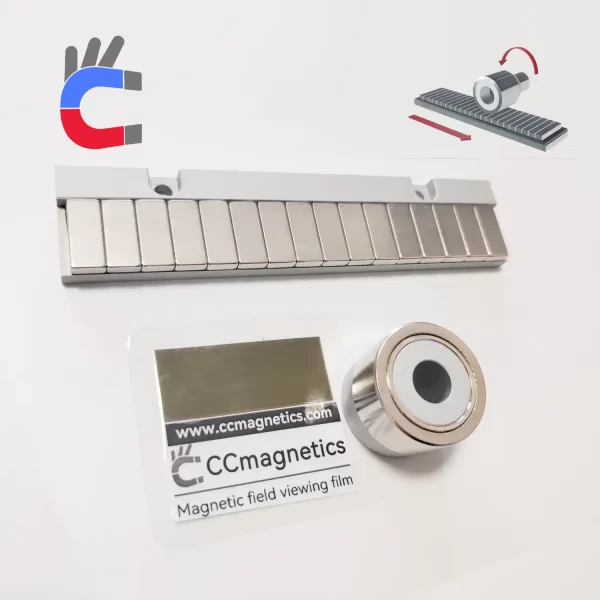

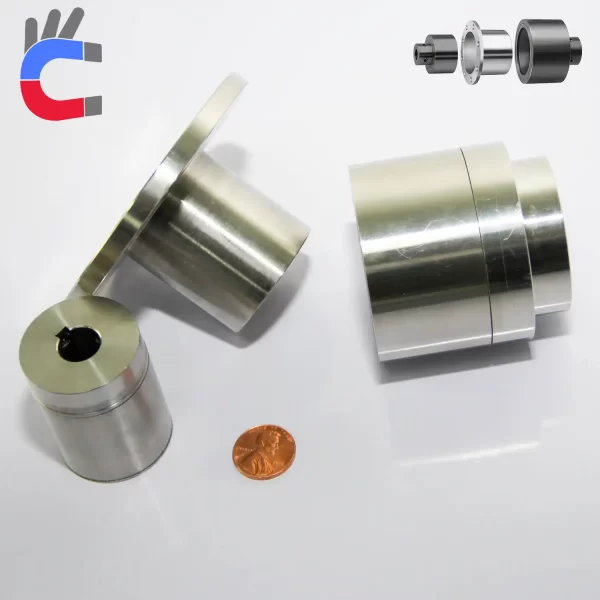

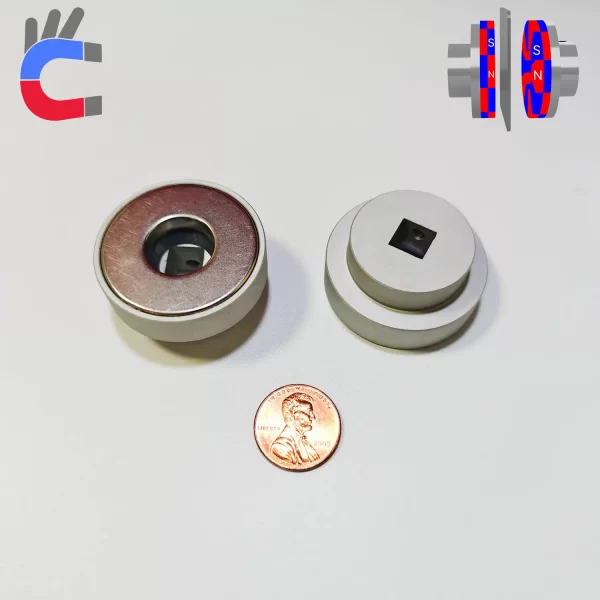

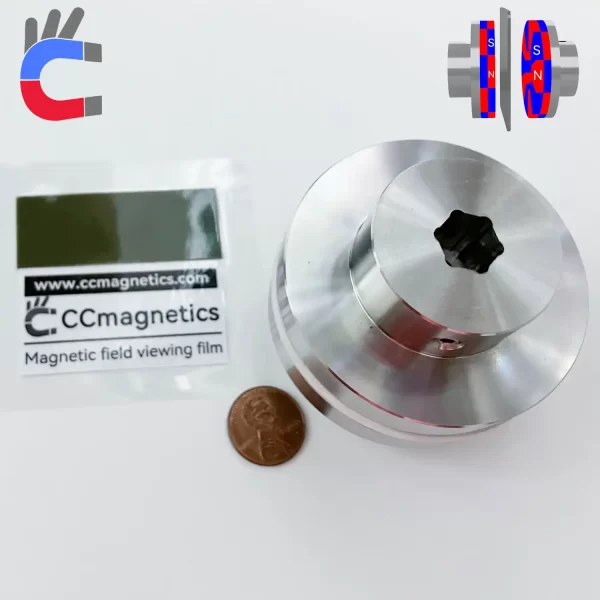

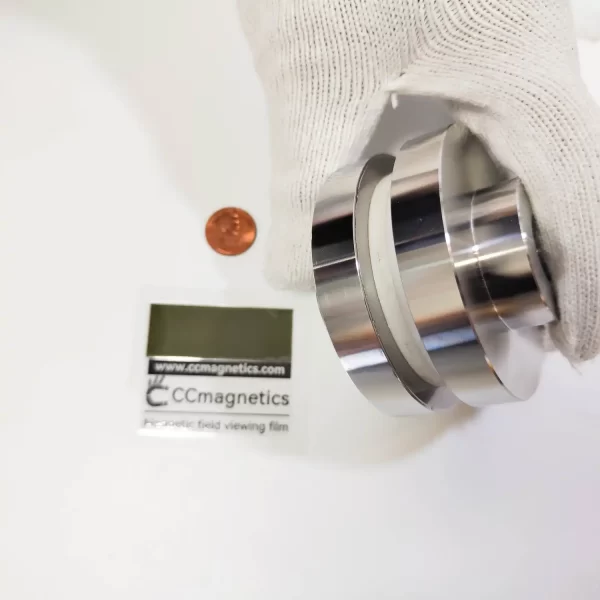

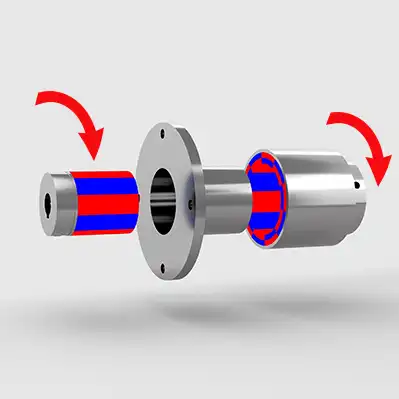

Co-Axial Magnetic Couplings

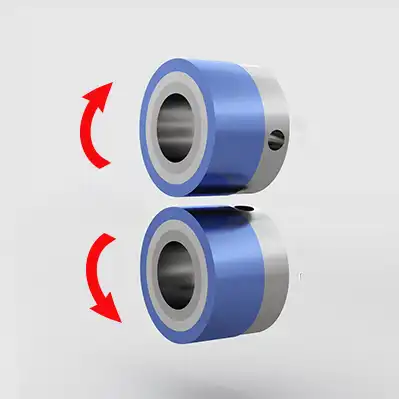

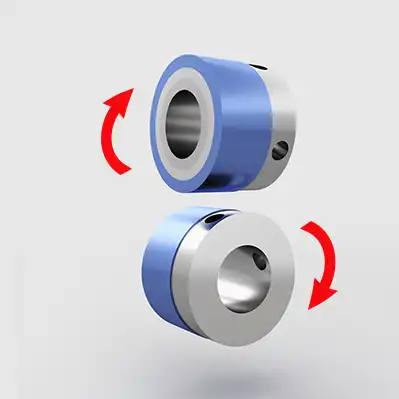

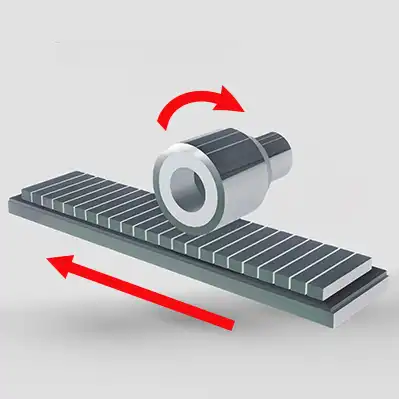

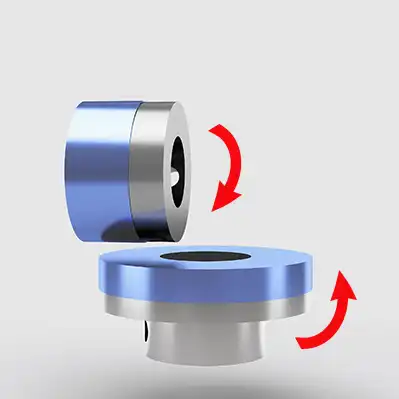

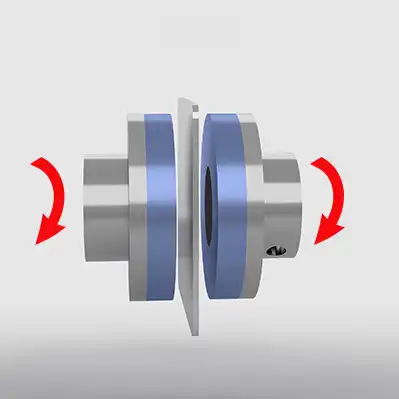

Co-Axial Magnetic Couplings transmit torque without contact by utilizing magnetic forces between the internal and external rotors. They provide a hermetically sealed separation between the driving and driven sides in pumps and agitators, effectively sealing hazardous liquids and gases.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語