Magnetic Wheel Manufacturer,Robot crawler wheel,Magnetic Drive Wheel,Magnetic Wheels Weight Loss for Crawler,Rubber Magnetic Wheel, Magnetic Holding Wheels,Magnetic Wheels for Robots,Magnetic Wheels Car

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

Unleash the climbing power of your robots with CCmagnetics' innovative magnetic wheels!

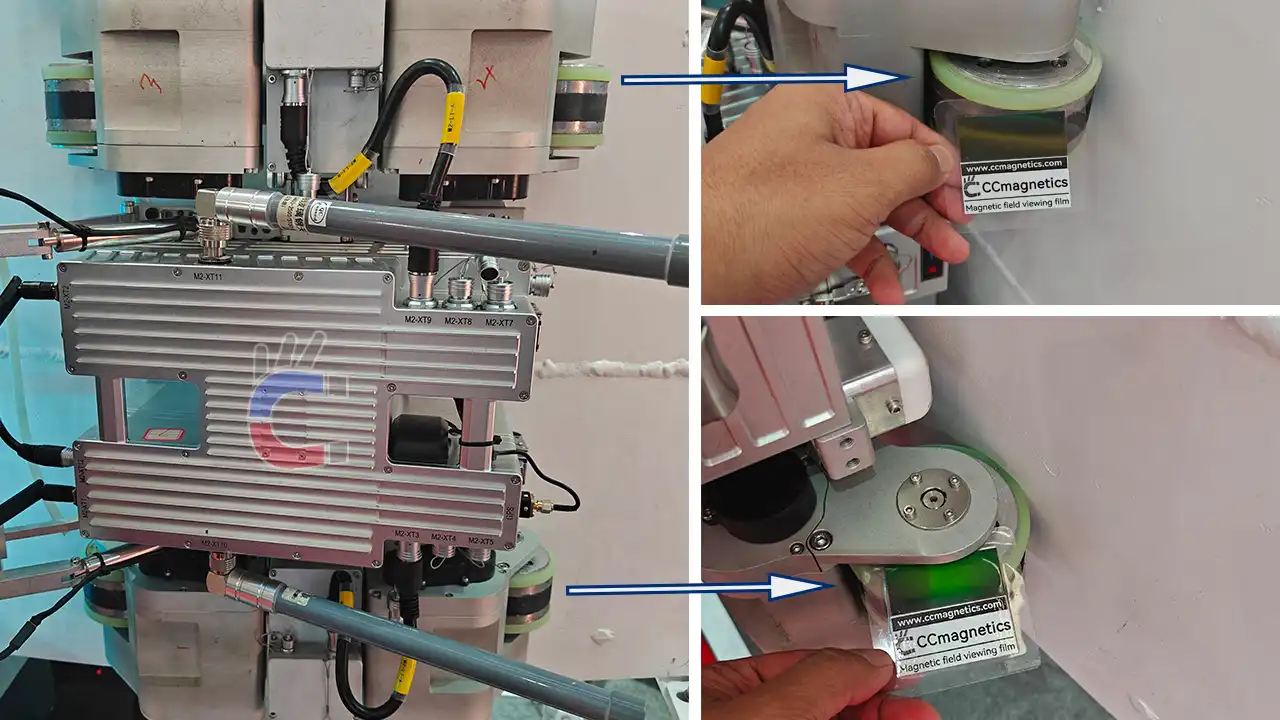

Robot magnetic wheels, primarily made of powerful neodymium magnets, offer superior adhesion to ferrous surfaces. This allows robots to effortlessly traverse vertical walls, making them ideal for applications like:

- Wall-climbing robots

- Ship inspections

- Wind turbine maintenance

- Exterior building cleaning

Parameter:

Tips

Table Title Explanation: PN stands for Part Number.

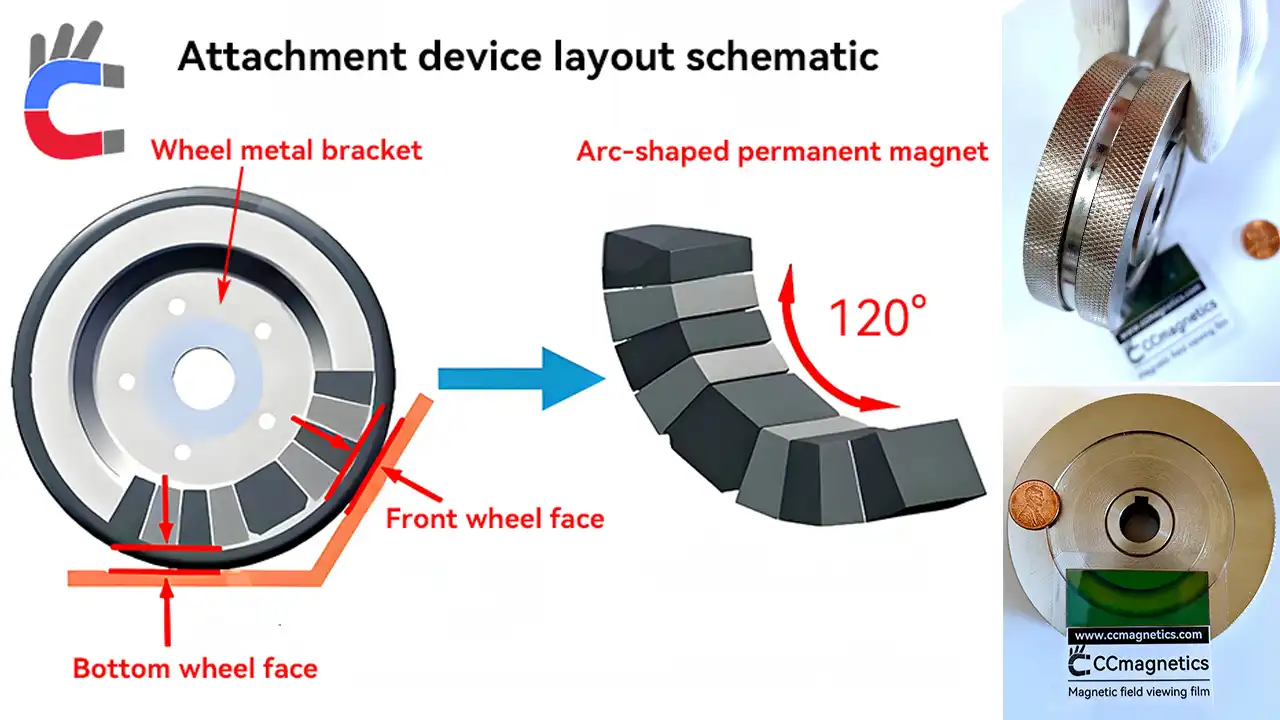

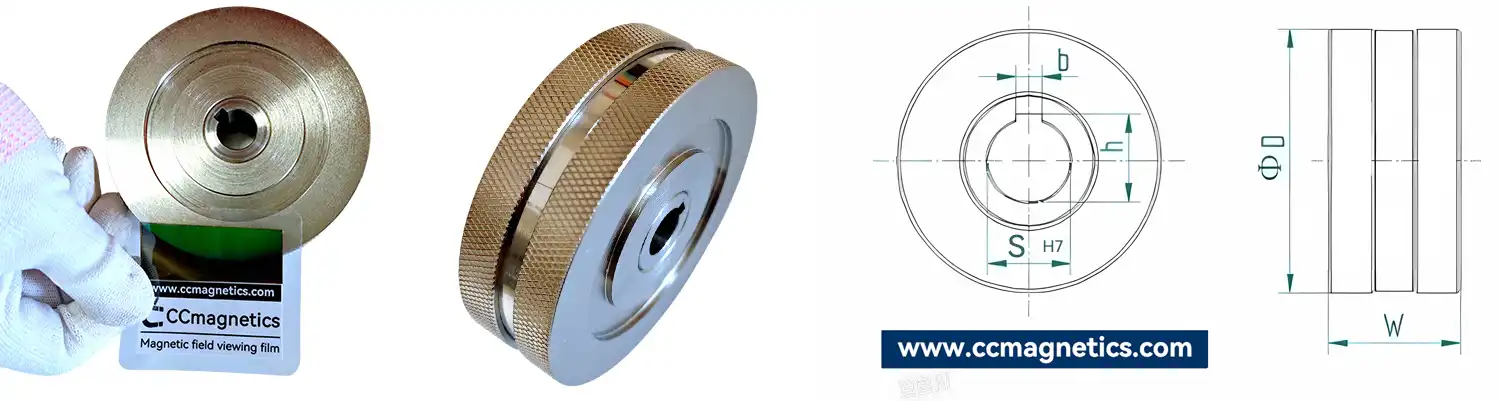

For the meanings of D, W, S, B, and H, please refer to the drawing. The value for S is a suggested range, and the final values for B, H, and S will be based on your specific requirements.

- Self-Wt is the weight of a single wheel.

- Load Cap is the maximum load capacity of a single wheel.

| PN | D (mm) | W (mm) | S (mm) | B & H (mm) | Self-Wt (kgs) | Pull Force (kgf) | Pull Force (N) |

|---|---|---|---|---|---|---|---|

| MW40-25 | 40 | 25 | 6 | Upon Request | ≈0.28 | 8 | 78 |

| MW50-25 | 50 | 25 | 6~8 | Upon Request | ≈0.4 | 10 | 98 |

| MW50-30 | 50 | 30 | 6~8 | Upon Request | ≈0.48 | 14 | 137 |

| MW50-35 | 50 | 35 | 6~8 | Upon Request | ≈0.56 | 18 | 176 |

| MW50-40 | 50 | 40 | 6~8 | Upon Request | ≈0.64 | 22 | 216 |

| MW50-45 | 50 | 45 | 6~8 | Upon Request | ≈0.72 | 26 | 255 |

| MW50-50 | 50 | 50 | 6~8 | Upon Request | ≈0.8 | 30 | 294 |

| MW60-25 | 60 | 25 | 8~12 | Upon Request | ≈0.59 | 15 | 147 |

| MW60-30 | 60 | 30 | 8~12 | Upon Request | ≈0.71 | 19 | 186 |

| MW60-35 | 60 | 35 | 8~12 | Upon Request | ≈0.83 | 23 | 225 |

| MW60-40 | 60 | 40 | 8~12 | Upon Request | ≈0.95 | 27 | 265 |

| MW60-45 | 60 | 45 | 8~12 | Upon Request | ≈1.07 | 31 | 304 |

| MW60-50 | 60 | 50 | 8~12 | Upon Request | ≈1.18 | 35 | 343 |

| MW63-25 | 63 | 25 | 8~12 | Upon Request | ≈0.61 | 15 | 147 |

| MW63-30 | 63 | 30 | 8~12 | Upon Request | ≈0.73 | 19 | 186 |

| MW63-35 | 63 | 35 | 8~12 | Upon Request | ≈0.86 | 23 | 225 |

| MW63-40 | 63 | 40 | 8~12 | Upon Request | ≈0.98 | 27 | 265 |

| MW63-45 | 63 | 45 | 8~12 | Upon Request | ≈1.11 | 31 | 304 |

| MW63-50 | 63 | 50 | 8~12 | Upon Request | ≈1.22 | 35 | 343 |

| MW65-25 | 65 | 25 | 12~16 | Upon Request | ≈0.63 | 20 | 196 |

| MW65-30 | 65 | 30 | 12~16 | Upon Request | ≈0.75 | 26 | 255 |

| MW65-35 | 65 | 35 | 12~16 | Upon Request | ≈0.88 | 32 | 314 |

| MW65-40 | 65 | 40 | 12~16 | Upon Request | ≈1 | 38 | 372 |

| MW65-45 | 65 | 45 | 12~16 | Upon Request | ≈1.13 | 44 | 431 |

| MW65-50 | 65 | 50 | 12~16 | Upon Request | ≈1.25 | 50 | 490 |

| MW80-25 | 80 | 25 | 12~16 | Upon Request | ≈0.8 | 40 | 392 |

| MW80-30 | 80 | 30 | 12~16 | Upon Request | ≈0.96 | 45 | 441 |

| MW80-35 | 80 | 35 | 12~16 | Upon Request | ≈1.12 | 50 | 490 |

| MW80-40 | 80 | 40 | 12~16 | Upon Request | ≈1.28 | 55 | 539 |

| MW80-45 | 80 | 45 | 12~16 | Upon Request | ≈1.44 | 60 | 588 |

| MW80-50 | 80 | 50 | 12~16 | Upon Request | ≈1.6 | 65 | 637 |

| MW90-25 | 90 | 25 | 12~16 | Upon Request | ≈1.19 | 50 | 490 |

| MW90-30 | 90 | 30 | 12~16 | Upon Request | ≈1.43 | 56 | 549 |

| MW90-35 | 90 | 35 | 12~16 | Upon Request | ≈1.67 | 62 | 608 |

| MW90-40 | 90 | 40 | 12~16 | Upon Request | ≈1.9 | 68 | 666 |

| MW90-45 | 90 | 45 | 12~16 | Upon Request | ≈2.14 | 74 | 725 |

| MW90-50 | 90 | 50 | 12~16 | Upon Request | ≈2.38 | 80 | 784 |

| MW100-25 | 100 | 25 | 12~16 | Upon Request | ≈1.6 | 50 | 490 |

| MW100-30 | 100 | 30 | 12~16 | Upon Request | ≈1.92 | 60 | 588 |

| MW100-35 | 100 | 35 | 12~16 | Upon Request | ≈2.24 | 70 | 686 |

| MW100-40 | 100 | 40 | 12~16 | Upon Request | ≈2.56 | 80 | 784 |

| MW100-45 | 100 | 45 | 12~16 | Upon Request | ≈2.88 | 90 | 882 |

| MW100-50 | 100 | 50 | 12~16 | Upon Request | ≈3.1 | 100 | 980 |

| MW110-30 | 110 | 30 | 16~20 | Upon Request | ≈2.1 | 55 | 539 |

| MW110-35 | 110 | 35 | 16~20 | Upon Request | ≈2.45 | 66 | 647 |

| MW110-40 | 110 | 40 | 16~20 | Upon Request | ≈2.8 | 77 | 755 |

| MW110-45 | 110 | 45 | 16~20 | Upon Request | ≈3.15 | 88 | 862 |

| MW110-50 | 110 | 50 | 16~20 | Upon Request | ≈3.5 | 99 | 970 |

| MW110-55 | 110 | 55 | 16~20 | Upon Request | ≈3.85 | 110 | 1078 |

| MW110-60 | 110 | 60 | 16~20 | Upon Request | ≈4.2 | 120 | 1176 |

| MW120-30 | 120 | 30 | 20~26 | Upon Request | ≈2.2 | 60 | 588 |

| MW120-35 | 120 | 35 | 20~26 | Upon Request | ≈2.58 | 72 | 706 |

| MW120-40 | 120 | 40 | 20~26 | Upon Request | ≈2.95 | 84 | 823 |

| MW120-45 | 120 | 45 | 20~26 | Upon Request | ≈3.33 | 96 | 941 |

| MW120-50 | 120 | 50 | 20~26 | Upon Request | ≈3.7 | 108 | 1058 |

| MW120-55 | 120 | 55 | 20~26 | Upon Request | ≈4.05 | 120 | 1176 |

| MW120-60 | 120 | 60 | 20~26 | Upon Request | ≈4.4 | 130 | 1274 |

| MW125-30 | 125 | 30 | 20~26 | Upon Request | ≈2.3 | 65 | 637 |

| MW125-35 | 125 | 35 | 20~26 | Upon Request | ≈2.69 | 78 | 764 |

| MW125-40 | 125 | 40 | 20~26 | Upon Request | ≈3.07 | 90 | 882 |

| MW125-45 | 125 | 45 | 20~26 | Upon Request | ≈3.45 | 103 | 1009 |

| MW125-50 | 125 | 50 | 20~26 | Upon Request | ≈3.83 | 115 | 1127 |

| MW125-55 | 125 | 55 | 20~26 | Upon Request | ≈4.22 | 128 | 1254 |

| MW125-60 | 125 | 60 | 20~26 | Upon Request | ≈4.6 | 140 | 1372 |

| MW130-30 | 130 | 30 | 20~28 | Upon Request | ≈2.5 | 70 | 686 |

| MW130-35 | 130 | 35 | 20~28 | Upon Request | ≈2.93 | 83 | 813 |

| MW130-40 | 130 | 40 | 20~28 | Upon Request | ≈3.35 | 97 | 951 |

| MW130-45 | 130 | 45 | 20~28 | Upon Request | ≈3.78 | 110 | 1078 |

| MW130-50 | 130 | 50 | 20~28 | Upon Request | ≈4.2 | 123 | 1205 |

| MW130-55 | 130 | 55 | 20~28 | Upon Request | ≈4.6 | 137 | 1343 |

| MW130-60 | 130 | 60 | 20~28 | Upon Request | ≈5 | 150 | 1470 |

| MW150-30 | 150 | 30 | 26~30 | Upon Request | ≈4.4 | 80 | 784 |

| MW150-35 | 150 | 35 | 26~30 | Upon Request | ≈5.1 | 93 | 911 |

| MW150-40 | 150 | 40 | 26~30 | Upon Request | ≈5.8 | 106 | 1039 |

| MW150-45 | 150 | 45 | 26~30 | Upon Request | ≈6.55 | 120 | 1176 |

| MW150-50 | 150 | 50 | 26~30 | Upon Request | ≈7.3 | 133 | 1303 |

| MW150-55 | 150 | 55 | 26~30 | Upon Request | ≈8 | 146 | 1431 |

| MW150-60 | 150 | 60 | 26~32 | Upon Request | ≈8 | 160 | 1568 |

| MW160-30 | 160 | 30 | 26~32 | Upon Request | ≈5.8 | 90 | 882 |

| MW160-35 | 160 | 35 | 26~32 | Upon Request | ≈6.8 | 103 | 1009 |

| MW160-40 | 160 | 40 | 26~32 | Upon Request | ≈7.8 | 117 | 1147 |

| MW160-45 | 160 | 45 | 26~32 | Upon Request | ≈8.8 | 130 | 1274 |

| MW160-50 | 160 | 50 | 26~32 | Upon Request | ≈9.8 | 143 | 1401 |

| MW160-55 | 160 | 55 | 26~32 | Upon Request | ≈10.8 | 157 | 1539 |

| MW160-60 | 160 | 60 | 26~32 | Upon Request | ≈11.8 | 170 | 1666 |

| MW180-30 | 180 | 30 | 28~36 | Upon Request | ≈9.2 | 100 | 980 |

| MW180-35 | 180 | 35 | 28~36 | Upon Request | ≈10.75 | 113 | 1107 |

| MW180-40 | 180 | 40 | 28~36 | Upon Request | ≈12.3 | 127 | 1245 |

| MW180-45 | 180 | 45 | 28~36 | Upon Request | ≈13.8 | 140 | 1372 |

| MW180-50 | 180 | 50 | 28~36 | Upon Request | ≈15.3 | 153 | 1499 |

| MW180-55 | 180 | 55 | 28~36 | Upon Request | ≈16.85 | 167 | 1637 |

| MW180-60 | 180 | 60 | 28~36 | Upon Request | ≈18.4 | 180 | 1764 |

| MW200-30 | 200 | 30 | 30~40 | Upon Request | ≈11 | 120 | 1176 |

| MW200-35 | 200 | 35 | 30~40 | Upon Request | ≈12.85 | 143 | 1401 |

| MW200-40 | 200 | 40 | 30~40 | Upon Request | ≈14.7 | 166 | 1627 |

| MW200-45 | 200 | 45 | 30~40 | Upon Request | ≈16.52 | 190 | 1862 |

| MW200-50 | 200 | 50 | 30~40 | Upon Request | ≈18.33 | 213 | 2087 |

| MW200-55 | 200 | 55 | 30~40 | Upon Request | ≈20.17 | 236 | 2313 |

| MW200-60 | 200 | 60 | 30~40 | Upon Request | ≈22 | 260 | 2548 |

| PN | D (in) | W (in) | S (in) | B & H (mm) | Self-Wt (lbs) | Pull Force (lbf) | Pull Force (N) |

|---|---|---|---|---|---|---|---|

| MW40-25 | 1.57 | 0.98 | 0.24 | Upon Request | ≈0.88 | ≈17.6 | 78 |

| MW50-25 | 1.97 | 0.98 | 0.24~0.47 | Upon Request | ≈0.9 | ≈22 | 98 |

| MW50-30 | 1.97 | 1.18 | 0.24~0.47 | Upon Request | ≈1.1 | ≈30.9 | 137 |

| MW50-35 | 1.97 | 1.38 | 0.24~0.47 | Upon Request | ≈1.2 | ≈39.7 | 176 |

| MW50-40 | 1.97 | 1.57 | 0.24~0.47 | Upon Request | ≈1.4 | ≈48.5 | 216 |

| MW50-45 | 1.97 | 1.77 | 0.24~0.47 | Upon Request | ≈1.6 | ≈57.3 | 255 |

| MW50-50 | 1.97 | 1.97 | 0.24~0.47 | Upon Request | ≈1.8 | ≈66.1 | 294 |

| MW60-25 | 2.36 | 0.98 | 0.31~0.47 | Upon Request | ≈1.3 | ≈33.1 | 147 |

| MW60-30 | 2.36 | 1.18 | 0.31~0.47 | Upon Request | ≈1.6 | ≈41.9 | 186 |

| MW60-35 | 2.36 | 1.38 | 0.31~0.47 | Upon Request | ≈1.8 | ≈50.7 | 225 |

| MW60-40 | 2.36 | 1.57 | 0.31~0.47 | Upon Request | ≈2.1 | ≈59.5 | 265 |

| MW60-45 | 2.36 | 1.77 | 0.31~0.47 | Upon Request | ≈2.4 | ≈68.3 | 304 |

| MW60-50 | 2.36 | 1.97 | 0.31~0.47 | Upon Request | ≈2.6 | ≈77.2 | 343 |

| MW63-25 | 2.48 | 0.98 | 0.31~0.47 | Upon Request | ≈1.3 | ≈33.1 | 147 |

| MW63-30 | 2.48 | 1.18 | 0.31~0.47 | Upon Request | ≈1.6 | ≈41.9 | 186 |

| MW63-35 | 2.48 | 1.38 | 0.31~0.47 | Upon Request | ≈1.9 | ≈50.7 | 225 |

| MW63-40 | 2.48 | 1.57 | 0.31~0.47 | Upon Request | ≈2.2 | ≈59.5 | 265 |

| MW63-45 | 2.48 | 1.77 | 0.31~0.47 | Upon Request | ≈2.4 | ≈68.3 | 304 |

| MW63-50 | 2.48 | 1.97 | 0.31~0.47 | Upon Request | ≈2.7 | ≈77.2 | 343 |

| MW65-25 | 2.56 | 0.98 | 0.47~0.63 | Upon Request | ≈1.4 | ≈44.1 | 196 |

| MW65-30 | 2.56 | 1.18 | 0.47~0.63 | Upon Request | ≈1.7 | ≈57.3 | 255 |

| MW65-35 | 2.56 | 1.38 | 0.47~0.63 | Upon Request | ≈1.9 | ≈70.5 | 314 |

| MW65-40 | 2.56 | 1.57 | 0.47~0.63 | Upon Request | ≈2.2 | ≈83.8 | 372 |

| MW65-45 | 2.56 | 1.77 | 0.47~0.63 | Upon Request | ≈2.5 | ≈97 | 431 |

| MW65-50 | 2.56 | 1.97 | 0.47~0.63 | Upon Request | ≈2.8 | ≈110.2 | 490 |

| MW80-25 | 3.15 | 0.98 | 0.47~0.63 | Upon Request | ≈1.8 | ≈88.2 | 392 |

| MW80-30 | 3.15 | 1.18 | 0.47~0.63 | Upon Request | ≈2.1 | ≈99.2 | 441 |

| MW80-35 | 3.15 | 1.38 | 0.47~0.63 | Upon Request | ≈2.5 | ≈110.2 | 490 |

| MW80-40 | 3.15 | 1.57 | 0.47~0.63 | Upon Request | ≈2.8 | ≈121.3 | 539 |

| MW80-45 | 3.15 | 1.77 | 0.47~0.63 | Upon Request | ≈3.2 | ≈132.3 | 588 |

| MW80-50 | 3.15 | 1.97 | 0.47~0.63 | Upon Request | ≈3.5 | ≈143.3 | 637 |

| MW90-25 | 3.54 | 0.98 | 0.47~0.63 | Upon Request | ≈2.6 | ≈110.2 | 490 |

| MW90-30 | 3.54 | 1.18 | 0.47~0.63 | Upon Request | ≈3.2 | ≈123.5 | 549 |

| MW90-35 | 3.54 | 1.38 | 0.47~0.63 | Upon Request | ≈3.7 | ≈136.7 | 608 |

| MW90-40 | 3.54 | 1.57 | 0.47~0.63 | Upon Request | ≈4.2 | ≈149.9 | 666 |

| MW90-45 | 3.54 | 1.77 | 0.47~0.63 | Upon Request | ≈4.7 | ≈163.1 | 725 |

| MW90-50 | 3.54 | 1.97 | 0.47~0.63 | Upon Request | ≈5.2 | ≈176.4 | 784 |

| MW100-25 | 3.94 | 0.98 | 0.47~0.63 | Upon Request | ≈3.5 | ≈110.2 | 490 |

| MW100-30 | 3.94 | 1.18 | 0.47~0.63 | Upon Request | ≈4.2 | ≈132.3 | 588 |

| MW100-35 | 3.94 | 1.38 | 0.47~0.63 | Upon Request | ≈4.9 | ≈154.3 | 686 |

| MW100-40 | 3.94 | 1.57 | 0.47~0.63 | Upon Request | ≈5.6 | ≈176.4 | 784 |

| MW100-45 | 3.94 | 1.77 | 0.47~0.63 | Upon Request | ≈6.3 | ≈198.4 | 882 |

| MW100-50 | 3.94 | 1.97 | 0.47~0.63 | Upon Request | ≈6.8 | ≈220.5 | 980 |

| MW110-30 | 4.33 | 1.18 | 0.63~0.79 | Upon Request | ≈4.6 | ≈121.3 | 539 |

| MW110-35 | 4.33 | 1.38 | 0.63~0.79 | Upon Request | ≈5.4 | ≈145.5 | 647 |

| MW110-40 | 4.33 | 1.57 | 0.63~0.79 | Upon Request | ≈6.2 | ≈169.8 | 755 |

| MW110-45 | 4.33 | 1.77 | 0.63~0.79 | Upon Request | ≈6.9 | ≈194 | 862 |

| MW110-50 | 4.33 | 1.97 | 0.63~0.79 | Upon Request | ≈7.7 | ≈218.3 | 970 |

| MW110-55 | 4.33 | 2.17 | 0.63~0.79 | Upon Request | ≈8.5 | ≈242.5 | 1078 |

| MW110-60 | 4.33 | 2.36 | 0.63~0.79 | Upon Request | ≈9.3 | ≈264.6 | 1176 |

| MW120-30 | 4.72 | 1.18 | 0.79~1.02 | Upon Request | ≈4.9 | ≈132.3 | 588 |

| MW120-35 | 4.72 | 1.38 | 0.79~1.02 | Upon Request | ≈5.7 | ≈158.7 | 706 |

| MW120-40 | 4.72 | 1.57 | 0.79~1.02 | Upon Request | ≈6.5 | ≈185.2 | 823 |

| MW120-45 | 4.72 | 1.77 | 0.79~1.02 | Upon Request | ≈7.3 | ≈211.6 | 941 |

| MW120-50 | 4.72 | 1.97 | 0.79~1.02 | Upon Request | ≈8.2 | ≈238.1 | 1058 |

| MW120-55 | 4.72 | 2.17 | 0.79~1.02 | Upon Request | ≈8.9 | ≈264.6 | 1176 |

| MW120-60 | 4.72 | 2.36 | 0.79~1.02 | Upon Request | ≈9.7 | ≈286.6 | 1274 |

| MW125-30 | 4.92 | 1.18 | 0.79~1.02 | Upon Request | ≈5.1 | ≈143.3 | 637 |

| MW125-35 | 4.92 | 1.38 | 0.79~1.02 | Upon Request | ≈5.9 | ≈172 | 764 |

| MW125-40 | 4.92 | 1.57 | 0.79~1.02 | Upon Request | ≈6.8 | ≈198.4 | 882 |

| MW125-45 | 4.92 | 1.77 | 0.79~1.02 | Upon Request | ≈7.6 | ≈227.1 | 1009 |

| MW125-50 | 4.92 | 1.97 | 0.79~1.02 | Upon Request | ≈8.4 | ≈253.5 | 1127 |

| MW125-55 | 4.92 | 2.17 | 0.79~1.02 | Upon Request | ≈9.3 | ≈282.2 | 1254 |

| MW125-60 | 4.92 | 2.36 | 0.79~1.02 | Upon Request | ≈10.1 | ≈308.6 | 1372 |

| MW130-30 | 5.12 | 1.18 | 0.79~1.10 | Upon Request | ≈5.5 | ≈154.3 | 686 |

| MW130-35 | 5.12 | 1.38 | 0.79~1.10 | Upon Request | ≈6.5 | ≈183 | 813 |

| MW130-40 | 5.12 | 1.57 | 0.79~1.10 | Upon Request | ≈7.4 | ≈213.8 | 951 |

| MW130-45 | 5.12 | 1.77 | 0.79~1.10 | Upon Request | ≈8.3 | ≈242.5 | 1078 |

| MW130-50 | 5.12 | 1.97 | 0.79~1.10 | Upon Request | ≈9.3 | ≈271.2 | 1205 |

| MW130-55 | 5.12 | 2.17 | 0.79~1.10 | Upon Request | ≈10.1 | ≈302 | 1343 |

| MW130-60 | 5.12 | 2.36 | 0.79~1.10 | Upon Request | ≈11 | ≈330.7 | 1470 |

| MW150-30 | 5.91 | 1.18 | 1.02~1.18 | Upon Request | ≈9.7 | ≈176.4 | 784 |

| MW150-35 | 5.91 | 1.38 | 1.02~1.18 | Upon Request | ≈11.2 | ≈205 | 911 |

| MW150-40 | 5.91 | 1.57 | 1.02~1.18 | Upon Request | ≈12.8 | ≈233.7 | 1039 |

| MW150-45 | 5.91 | 1.77 | 1.02~1.18 | Upon Request | ≈14.4 | ≈264.6 | 1176 |

| MW150-50 | 5.91 | 1.97 | 1.02~1.18 | Upon Request | ≈16.1 | ≈293.2 | 1303 |

| MW150-55 | 5.91 | 2.17 | 1.02~1.18 | Upon Request | ≈17.6 | ≈321.9 | 1431 |

| MW150-60 | 5.91 | 2.36 | 1.02~1.26 | Upon Request | ≈17.6 | ≈352.7 | 1568 |

| MW160-30 | 6.3 | 1.18 | 1.02~1.26 | Upon Request | ≈12.8 | ≈198.4 | 882 |

| MW160-35 | 6.3 | 1.38 | 1.02~1.26 | Upon Request | ≈15 | ≈227.1 | 1009 |

| MW160-40 | 6.3 | 1.57 | 1.02~1.26 | Upon Request | ≈17.2 | ≈257.9 | 1147 |

| MW160-45 | 6.3 | 1.77 | 1.02~1.26 | Upon Request | ≈19.4 | ≈286.6 | 1274 |

| MW160-50 | 6.3 | 1.97 | 1.02~1.26 | Upon Request | ≈21.6 | ≈315.3 | 1401 |

| MW160-55 | 6.3 | 2.17 | 1.02~1.26 | Upon Request | ≈23.8 | ≈346.1 | 1539 |

| MW160-60 | 6.3 | 2.36 | 1.02~1.26 | Upon Request | ≈26 | ≈374.8 | 1666 |

| MW180-30 | 7.09 | 1.18 | 1.10~1.42 | Upon Request | ≈20.3 | ≈220.5 | 980 |

| MW180-35 | 7.09 | 1.38 | 1.10~1.42 | Upon Request | ≈23.7 | ≈249.1 | 1107 |

| MW180-40 | 7.09 | 1.57 | 1.10~1.42 | Upon Request | ≈27.1 | ≈280 | 1245 |

| MW180-45 | 7.09 | 1.77 | 1.10~1.42 | Upon Request | ≈30.4 | ≈308.6 | 1372 |

| MW180-50 | 7.09 | 1.97 | 1.10~1.42 | Upon Request | ≈33.7 | ≈337.3 | 1499 |

| MW180-55 | 7.09 | 2.17 | 1.10~1.42 | Upon Request | ≈37.1 | ≈368.2 | 1637 |

| MW180-60 | 7.09 | 2.36 | 1.10~1.42 | Upon Request | ≈40.6 | ≈396.8 | 1764 |

| MW200-30 | 7.87 | 1.18 | 1.18~1.57 | Upon Request | ≈24.3 | ≈264.6 | 1176 |

| MW200-35 | 7.87 | 1.38 | 1.18~1.57 | Upon Request | ≈28.3 | ≈315.3 | 1401 |

| MW200-40 | 7.87 | 1.57 | 1.18~1.57 | Upon Request | ≈32.4 | ≈366 | 1627 |

| MW200-45 | 7.87 | 1.77 | 1.18~1.57 | Upon Request | ≈36.4 | ≈418.9 | 1862 |

| MW200-50 | 7.87 | 1.97 | 1.18~1.57 | Upon Request | ≈40.4 | ≈469.6 | 2087 |

| MW200-55 | 7.87 | 2.17 | 1.18~1.57 | Upon Request | ≈44.5 | ≈520.3 | 2313 |

| MW200-60 | 7.87 | 2.36 | 1.18~1.57 | Upon Request | ≈48.5 | ≈573.2 | 2548 |

Note:

- About vertical hanging load, The data in the table is very conservative. For example, the tested data for MW50-25 is 13.5 kgf, but we list 12kgs. Learn more about how the robot magnetic wheel calculation works.

- S, H, and B are based on customer needs and fully specified by the customer. The S value is our recommended diameter range; But the final diameter is specified by the customer.

- All sizes of magnetic hanging wheels can be customized with rubber tires. The rubber tires can be replaced anytime.

- If the magnetic wheel size you need is not in the table, we can also customize based on the CAD drawing you provide.

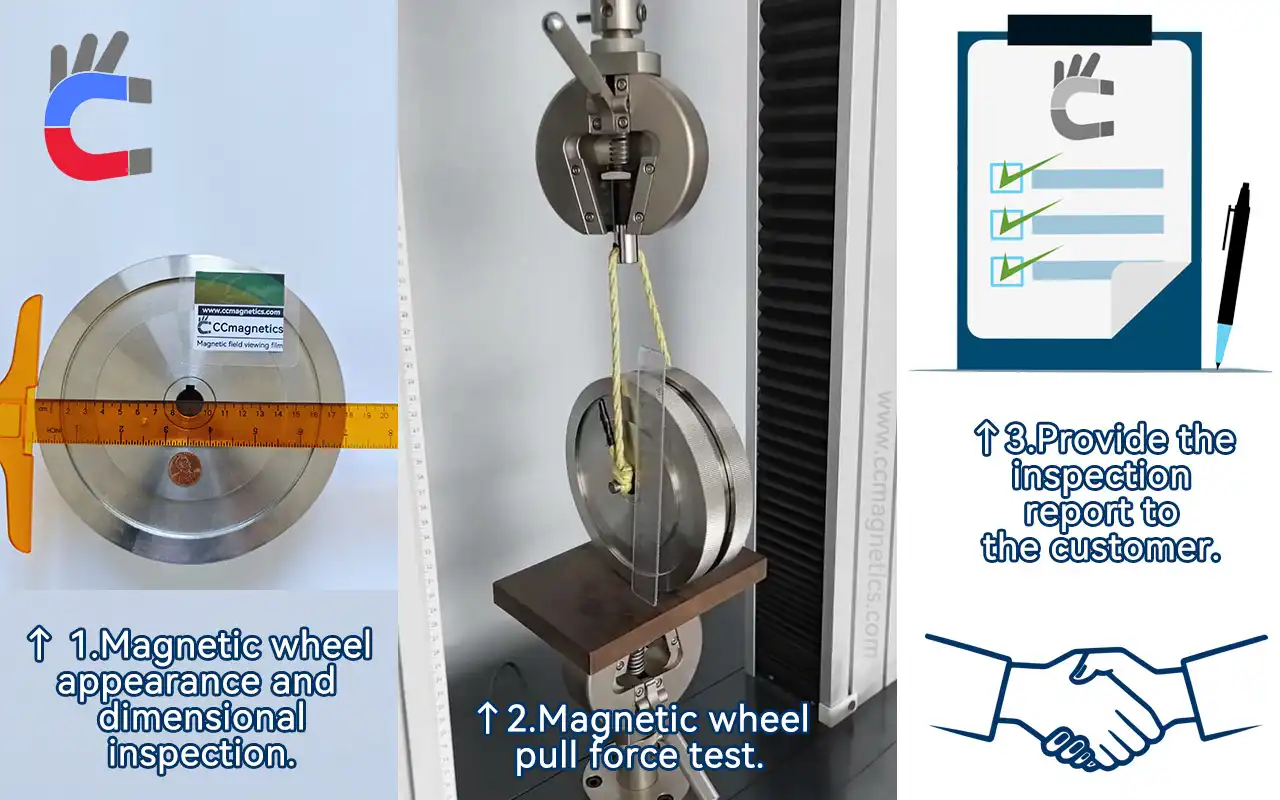

- Provide customers with free tensile test reports.

Provide customers with free tensile test reports.

Application:

- Wall Climbing Robot Magnetic Wheel

- Ship sandblasting robot magnetic wheel

- Magnetic Climbing Robot Wheel

- Robot Magnetic Climbing Wheel

- Neodymium Magnetic Wheel

- Oil Pipeline Robot Wall Climbing Wheel

- Ship Derusting and Painting Robot Magnetic Wheel

- Permanent magnetic wheel

Features:

- Strong Magnetic Adhesion:Neodymium magnets provide exceptional grip on ferrous surfaces.

- Versatile Size Options: Choose from a range of diameters (40mm - 200mm) to suit your specific robot needs.

- High Weight Capacity: Supports robots up to 1040kg (when used in sets of four).

- Customizable Traction: Enhance grip and stability with optional non-slip rubber rings.

- Wide Operating Temperature: Performs reliably in diverse environments (-40°C to 80°C).

Q&A: Magnetic Wheels for Wall-Climbing Robots

Note: This is the limit of magnetic adhesion, not the safe working load. For wall-climbing robots, the actual payload capacity depends on the friction coefficient (typically 20%-30% of the Pull Force).

Subtract the total weight of the magnetic wheel from the total suspension weight of the magnetic wheel, which is: (4*90kg) - (4*8.5kg)=326kg.

So 326kg is the total body weight of the robot.

Additional Customization Options: Custom Rubber Tires.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

susp1216 –

Danke, habe mein Problem gelöst.

kristenbellows18 –

fast shipping, good price and good quality, highly recommended

walterfuentes4 –

thank you a lot.