Upgrade Your Drivetrain with the Next Generation of Magnetic Transmission

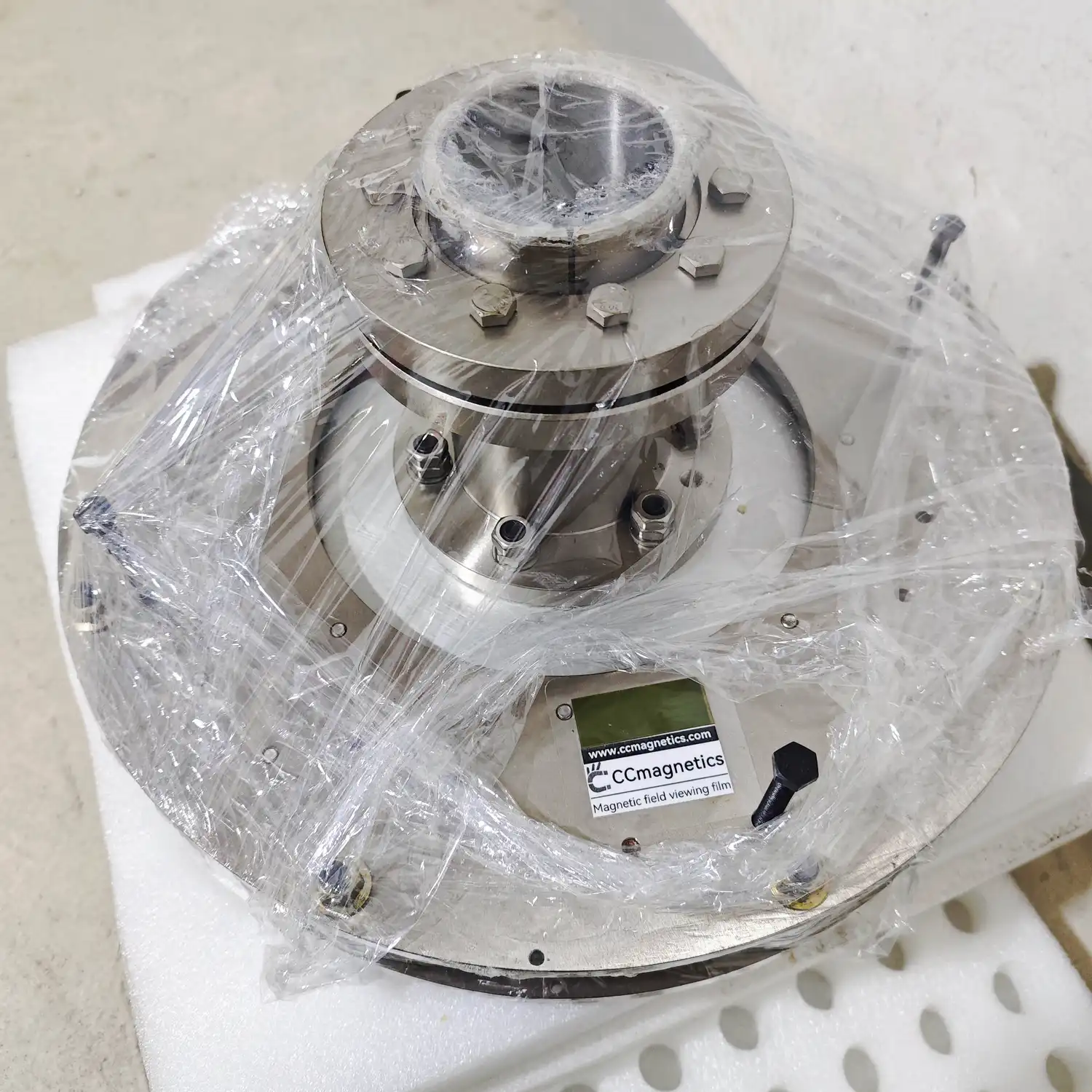

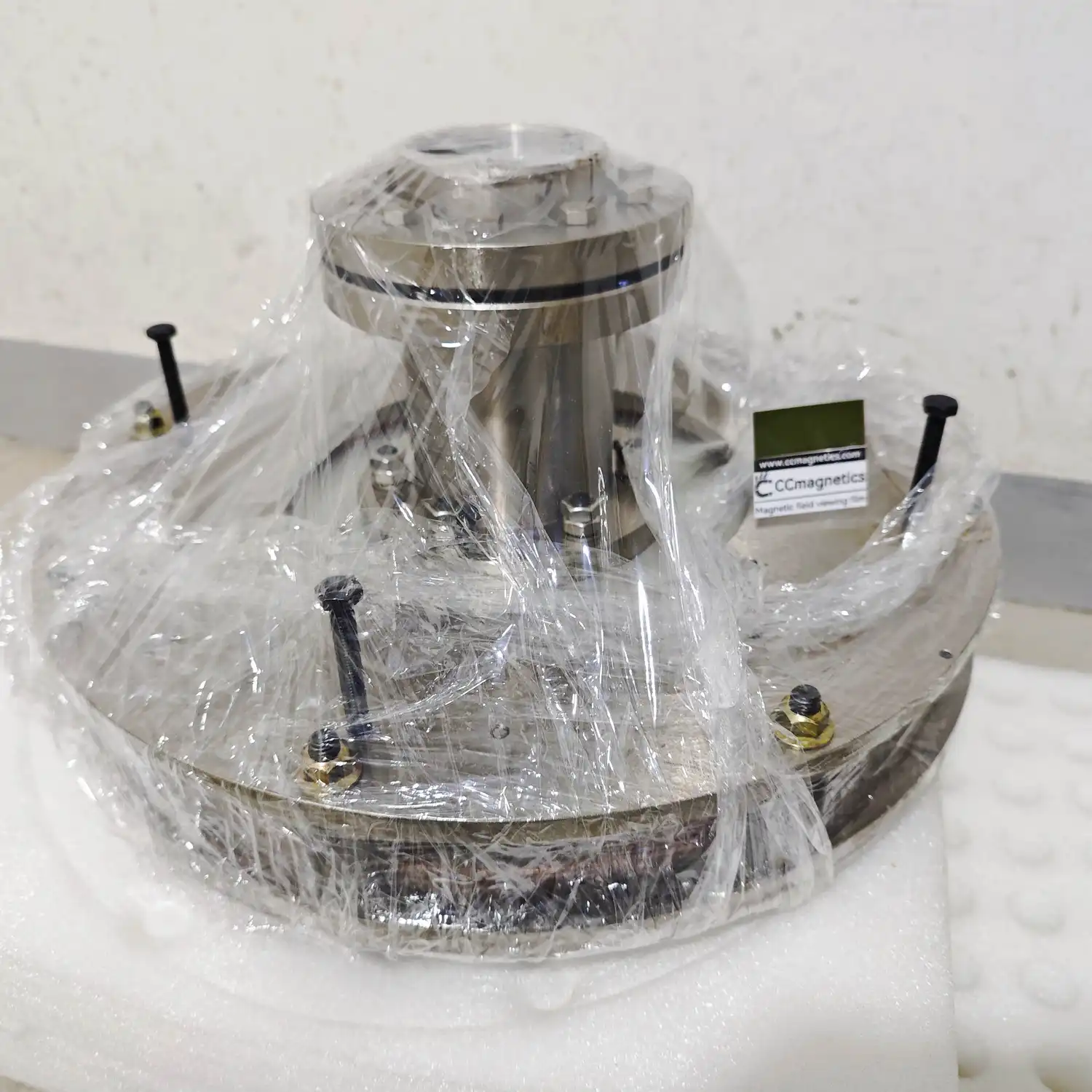

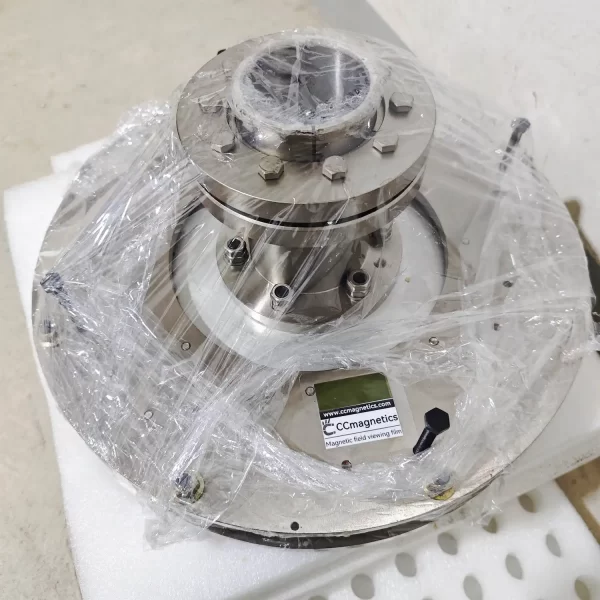

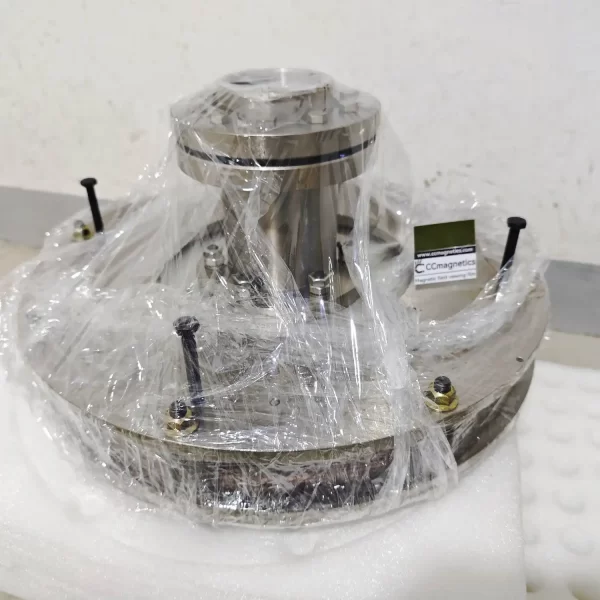

Stop relying on messy, leaking hydraulic couplers or inefficient eddy current systems. The CCmagnetics Fixed Gap Magnetic Coupling represents the future of industrial power transmission. Designed for heavy-duty applications in mining, HVAC, material handling, and fluid processing, this coupling solves the common pain points of traditional drive systems.

Why Choose Fixed Gap Technology?

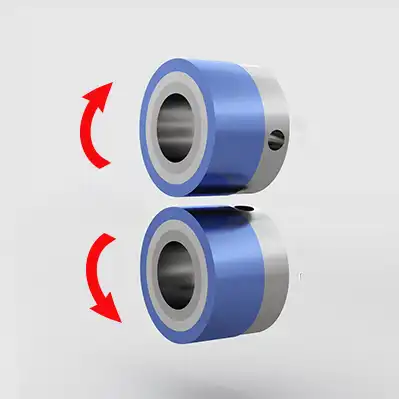

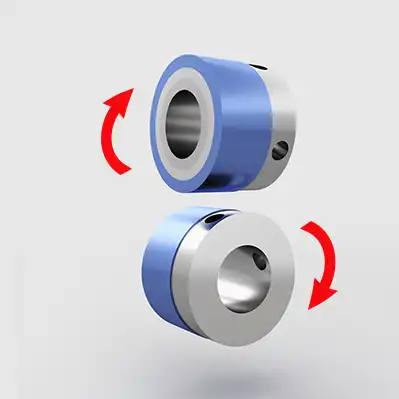

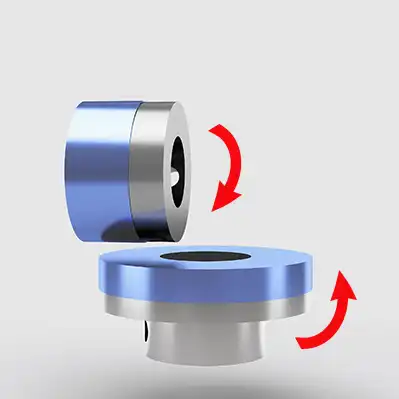

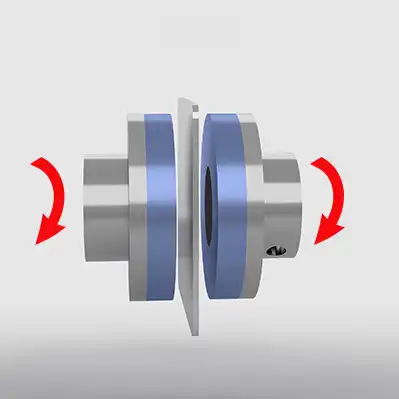

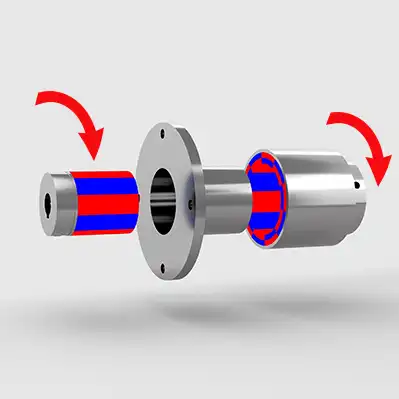

- Synchronous Power: We use permanent magnets to lock the drive and load in perfect sync. This means no "slip," no wasted energy, and no heat generation.

- Equipment Protection: The magnetic air gap acts as a cushion. If your machine jams, the magnetic field allows for elastic displacement, preventing catastrophic mechanical failure on your motor shaft.

- Zero Maintenance: With no physical contact between rotors and no oil to change, this unit is virtually maintenance-free for its entire 15+ year design life.

Comparison:

- Vs. Hydraulic: No oil leaks, no fusible plugs to replace, and significantly higher efficiency.

- Vs. Eddy Current: No heat generation, fully sealed against dust, and zero axial force damaging your bearings.

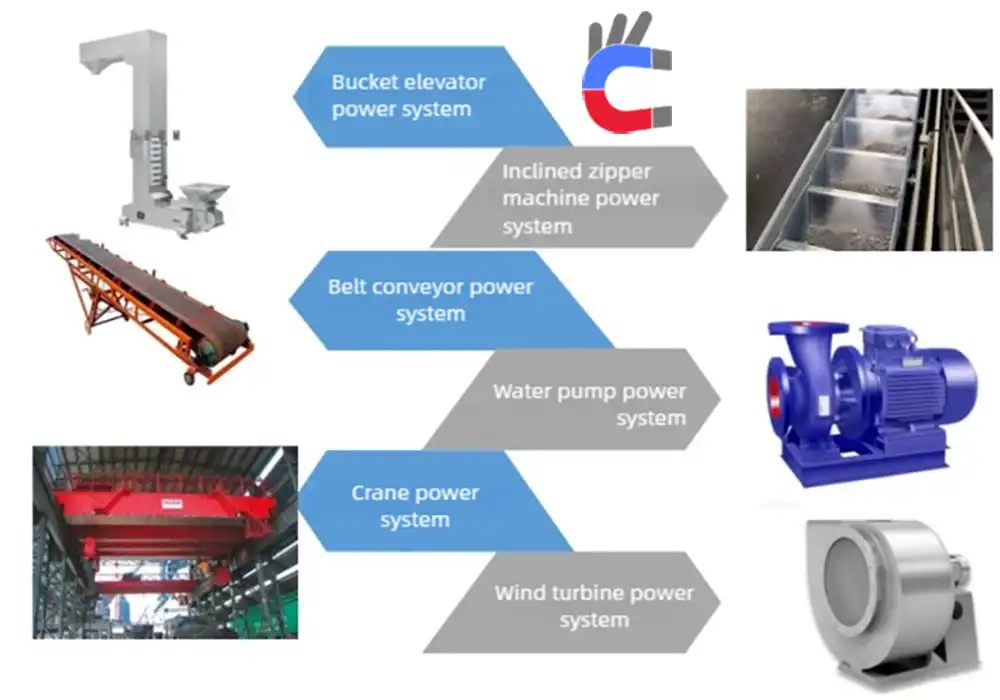

Ideal Applications:

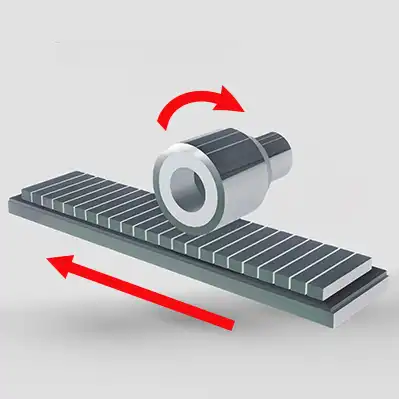

- Belt Conveyors & Bucket Elevators

- Centrifugal Pumps & Fans

- Crushers & Mixers

- Operations requiring frequent reversing or vertical mounting.

Technical Specifications:

- Type: Fixed Gap Permanent Magnetic Coupling

- Efficiency: ~100% (Synchronous)

- Cooling: Passive (No fins required)

- Protection: Overload slip protection with auto-recovery

- Material: Carbon Steel / Stainless Steel housing

How to Get Started

We can produce fixed gap magnetic couplings based on your drawings. If you don't have drawings, please provide the following key information. After our evaluation, we'll give you a quote. Once you accept the quote and make payment, we'll design the drawings for your coupler. Finally, we'll deliver the magnetic coupler and related test reports according to the confirmed drawings.

| No. | Parameter | Description/Requirement | Filling Instructions |

|---|---|---|---|

| 1 | Motor Power | (Kw/HP)? | |

| 2 | Motor Speed | RPM | |

| 3 | Gearbox (Yes/No) & Ratio | With reducer? | |

| 4 | Torque | N.m / in.lbs acceptable. | |

| 5 | Operating Temperature | Celsius / Fahrenheit acceptable. | |

| 6 | Operating Pressure | Mpa | |

| 7 | Working Medium | e.g., gas, liquid, etc. | |

| 8 | Material Requirements | e.g., stainless steel/ Q235 iron | |

| 9 | Connected Equipment | e.g., Pump/Agitator | |

| 10 | Support Requirement | e.g., Bellhousings | |

| 11 | Quantity Needed | What quantity do you need? |

Note: You can download the demand form, fill it out and email it to us.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

jdkshepard –

good!

billeysimp –

Great!

skylarthompson44 –

Great communication, prompt delivery