Let us help you.

Devote all your time and energy to your magnetic encoder project, leave the encoder magnetic ring issues to us.

Devote all your time and energy to your magnetic encoder project, leave the encoder magnetic ring issues to us.

CCmagnetics has compiled and published specifications for 1,000 + magnetic rings. These rings require no mold or magnetization coil fees, saving you significant time and budget. Simply find the specifications you need, copy the corresponding SKU number, and contact us for assistance.

Find rings by OD (mm). No tooling fees. Low MOQ (if in stock).

Find Your Magnetic Ring by Outer Diameter (OD)

Easily find the rings you need by their outside diameter (OD) in millimeters. These rings don't require you to pay for expensive tooling. Minimum order quantities are very low, as long as we have them in stock.

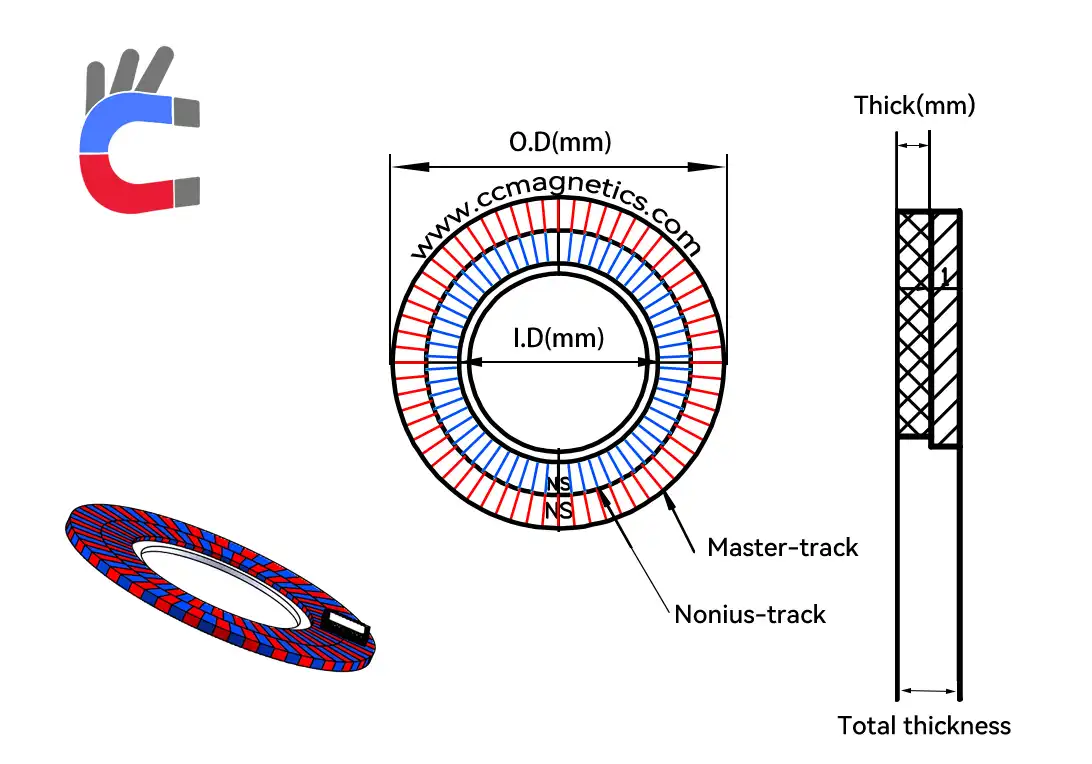

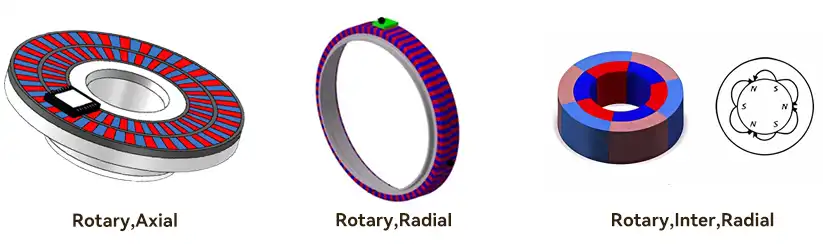

The main magnetization method are as follows. If you have any special requirements, please feel free to contact our staff.

| Material Type | Typical Applications |

|---|---|

| Injection molded ferrite magnets | Commonly used in servo motor sensors, offering high precision and excellent shock resistance. |

| Bonded neodymium magnets | Often used in encoders with less than 50 poles or in motor magnets, providing a good balance of cost and performance. |

| Injection molded neodymium magnets | Widely used in servo motor sensors and motor magnets, offering better shock resistance compared to traditional sintered NdFeB magnets. |

| Ferrite magnets | Commonly found in Hall sensors. They offer the highest precision but have the weakest shock resistance, often requiring a metal carrier. |

| Neodymium magnets | If high surface magnetism is the primary goal, this is the preferred choice. |

| Copper metal ring/ injection molded neodymium magnets | Designed for improved concentricity and wear resistance. Often used in encoder magnets to ensure accurate positioning. |

| Copper metal ring/ injection molded ferrite magnets | Designed for improved concentricity and wear resistance. Often used in encoder magnets to ensure accurate positioning. |

| Sintered NdFeB magnets | Sintered NdFeB magnets are commonly used in motor magnets, offering very high surface magnetism. |

| Vulcanized rubber magnet material | This material is the most advanced for encoder magnets, offering high magnetic pole precision and excellent shock resistance, making it popular for robotic magnetic encoders. |

| NdFeB plastic coating | This coating improves the flexibility of NdFeB magnets. |

| Sintered neodymium magnets | If high surface magnetism is the primary goal, this is the preferred choice; however, it doesn't perform as well as hot-pressed magnets. |

| Rubber magnets | These magnets are soft and have relatively low magnetic pole precision. |

The surface magnetic field refers to the magnetic field on the surface of the magnetic ring. Usually, the Hall sensor can detect a signal with a field strength of 100 Gauss (or 10 millitesla) at a distance of 1 mm from the magnetic ring. Of course, some special applications may require different parameters.

Once you've found a magnetic ring of interest, please note its SKU and contact our team. If you require a drawing, please specify in your message.CCmagnetics ensures a customer response within 24 hours.

This is the download link for our encoder magnets catalog, but it does not include specific magnet specifications.

Please note that we do not provide a static catalog due to frequent updates to our magnetic ring database. To access detailed specifications, kindly visit the individual product pages within our website.