magnetic coupling pump,magnetic coupling torque calculation,magnetic coupled pump,magnetically coupled pumps,magnetically coupled pump,magnetic pump coupling,Magnetic Driving Shaft Couplings,Magnetic Coupling Assembly

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

What is magnetic coupling pump ?

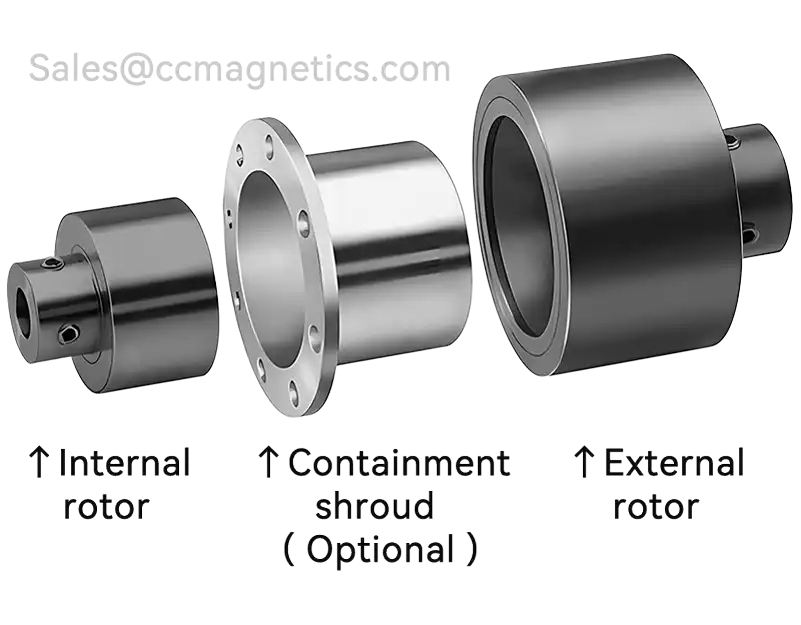

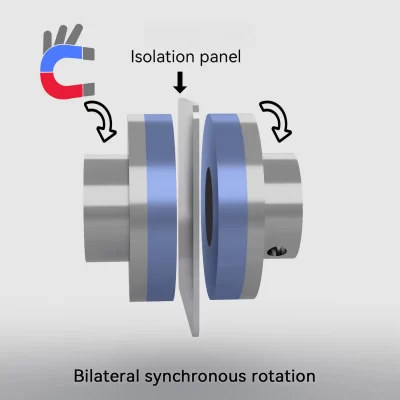

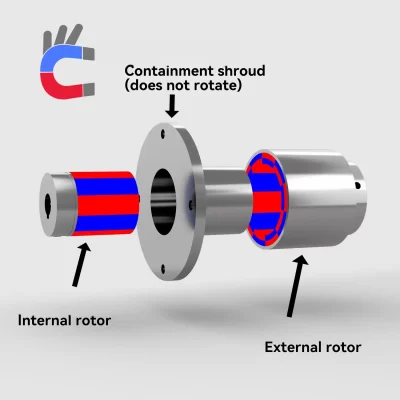

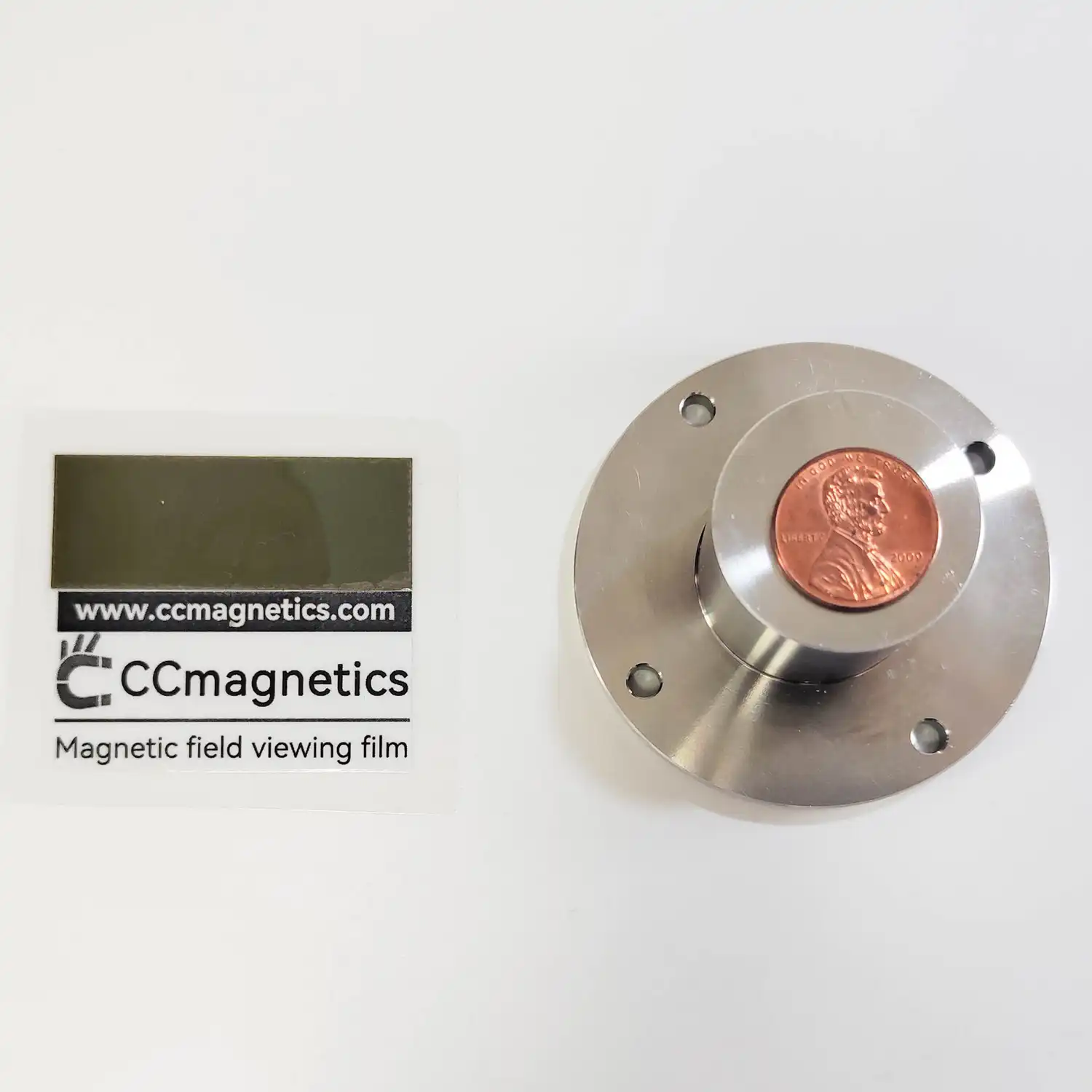

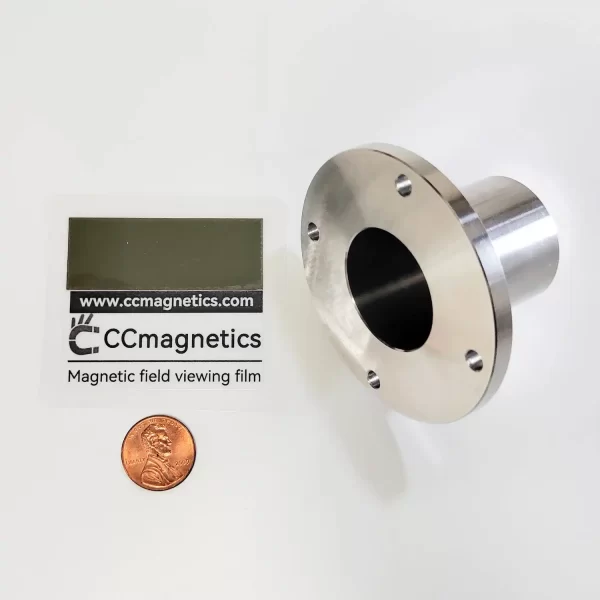

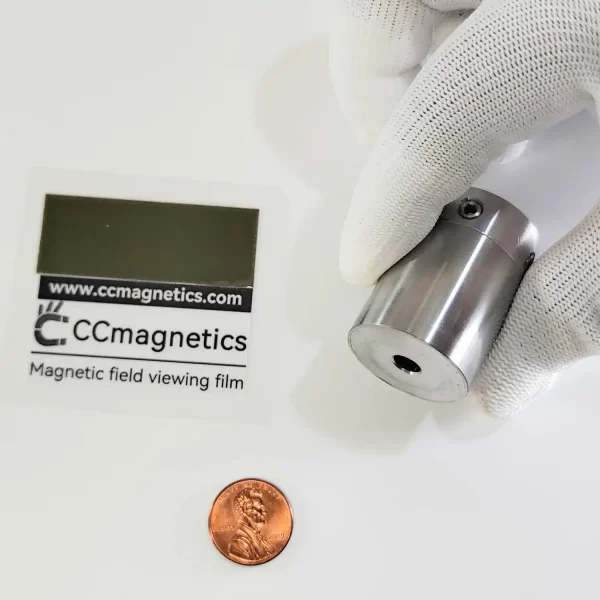

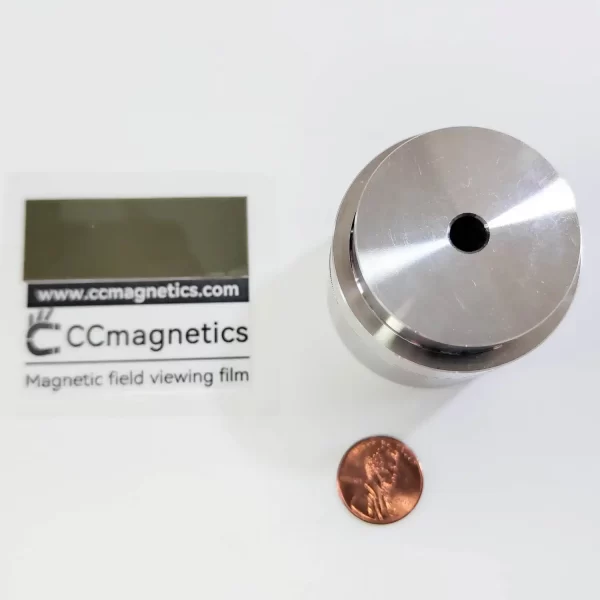

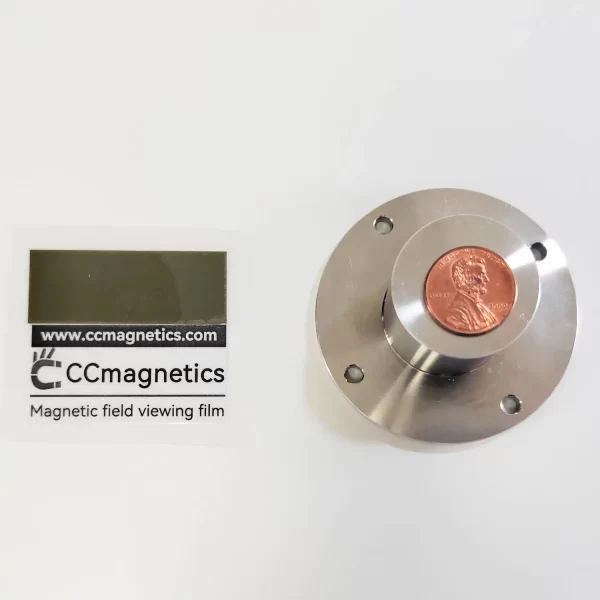

The magnetic coupling pump transmit the torque without contact through magnetic forces between the internal and external rotor. They ensure hermetic separation between driving and driven side in pumps and agitators sealing hazardous liquids and gases reliably.

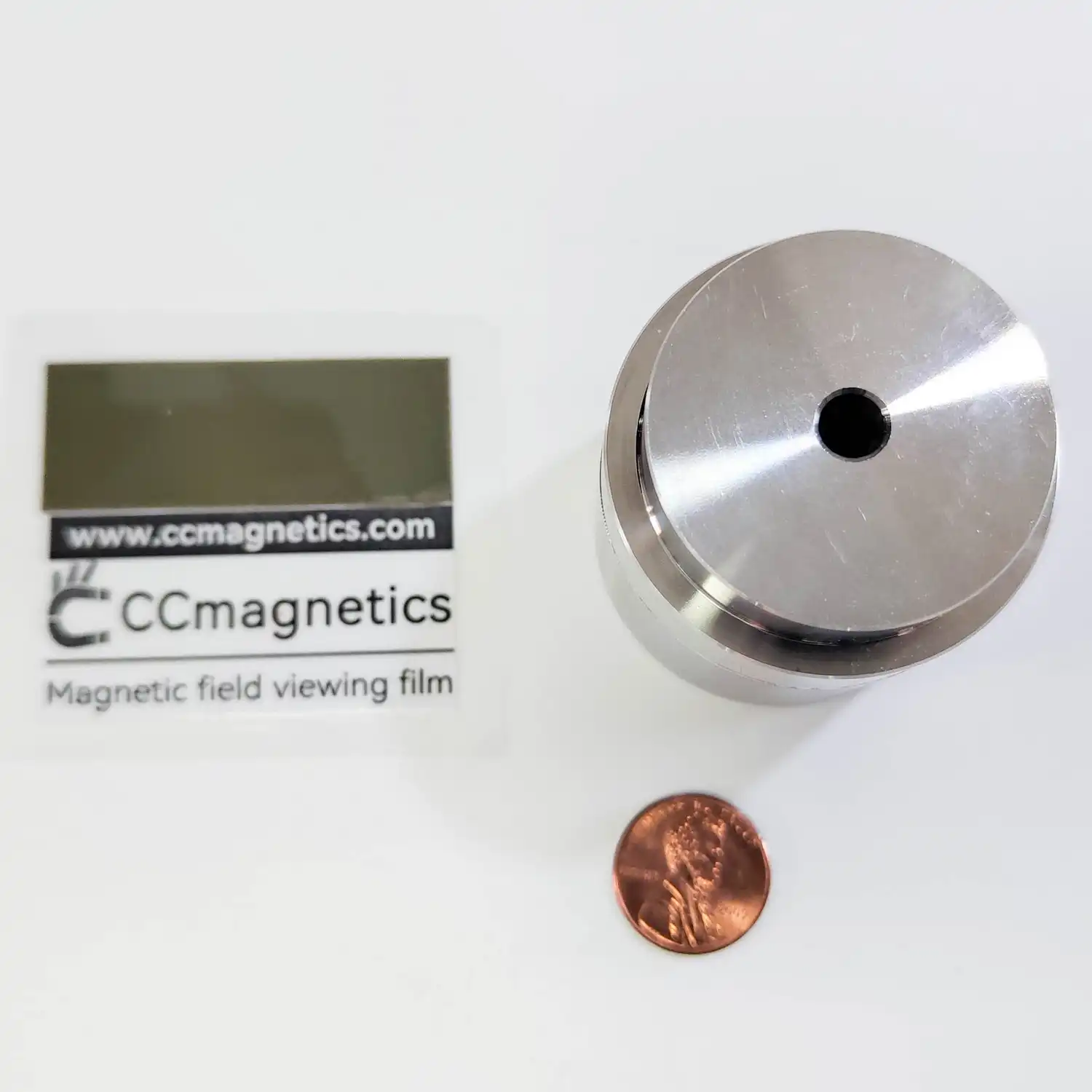

The magnetic coupling pump consists of an external and an internal rotor. The external rotor has got high-quality, permanent magnets of changing polarity on the inner side while the internal rotor has got them on the outside.The external rotor is usually fixed on the drive side and the magnets are glued in the keyways. The magnets of the internal rotor on the driven side are fully encapsulated.

How magnetic coupling pump work?

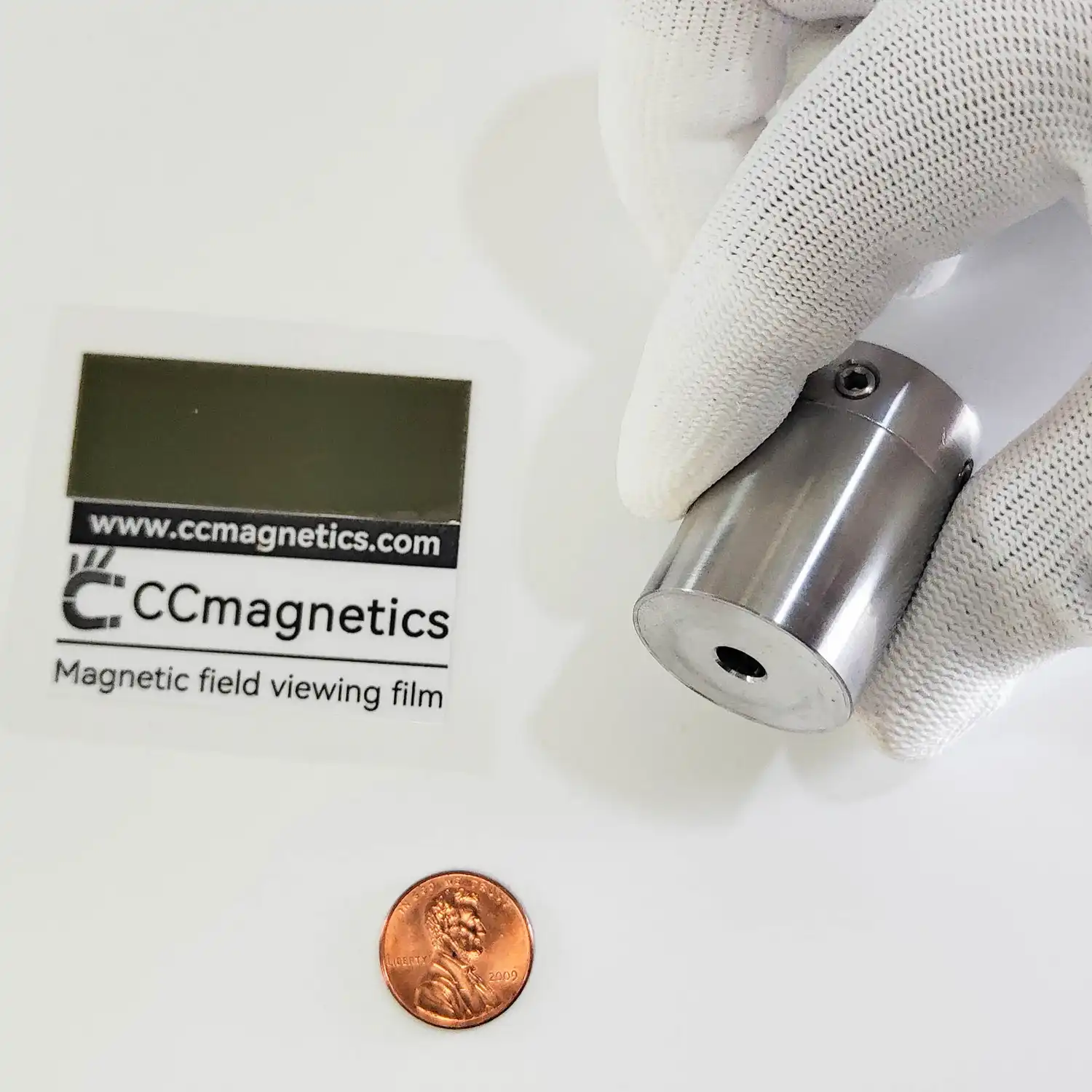

The magnetic coupling pump consists of three parts. The external rotor consists of a series of rare earth magnets that are ground, potted and attached to the inside diameter of a steel hub. The Internal rotor consists of a series of rare earth magnets that are ground, potted and attached to the outside diameter of a steel rotor. The sealing is achieved statically.

Then there is a synchronous operation under a constant torsion angle. If the maximum coupling torque and the maximum torsion angle are exceeded, the power transmission is interrupted.Since the torque transmission of the magnetic coupling pump is interrupted, the motor will be effectively protected.The motor will not burn out due to absolute torque transmission.

Application of magnetic coupling pump

Typical applications: Gear pumps, centrifugal pumps, screw spindle pumps, agitators, PU foaming lines.

The magnetic coupling pump parameter

Note:Website drawings and product catalog drawings are for reference only. They can help customers quickly understand the high cost performance of our magnetic couplings, so as to quickly compare and make decisions. We will provide formal engineering drawings after payment. These formal drawings contain all engineering details.

| PN | D (mm) | ΦC (mm) | M | B (mm) | ΦA (mm) | L (mm) | F (mm) | Torque NORMAL [N.m] |

|---|---|---|---|---|---|---|---|---|

| XC45-1 | 45 | 6~19 | M4 | 27 | 6~15 | 67 | 65 | 1 |

| XC45-2 | 45 | 6~19 | M4 | 27 | 6~15 | 67 | 65 | 2 |

| XC60-3 | 60 | 12~24 | M5 | 35 | 8~18 | 78 | 90 | 3 |

| XC69-3 | 69 | 5~19 | M4/M5 | 28 | 8~16 | 69.5 | 78 | 3 |

| XC60-5 | 60 | 12~24 | M5 | 35 | 8~18 | 78 | 90 | 5 |

| XC80-8 | 80 | 15~28 | M6 | 48 | 10~20 | 90 | 115 | 8 |

| XC94-7 | 94.5 | 9~28 | M5/M6 | 35 | 12~22 | 81.3 | 89.5 | 7 |

| XC110-10 | 110 | 12~28 | M6 | 45 | 12~28 | 102 | 118 | 10 |

| XC80-11 | 80 | 15~28 | M6 | 48 | 10~20 | 90 | 115 | 11 |

| XC90-15 | 90 | 15~28 | M6 | 48 | 10~20 | 90 | 115 | 15 |

| XC94-14 | 94.5 | 9~38 | M5/M8 | 35 | 12~22 | 108 | 89.5 | 14 |

| XC100-25 | 100 | 9~38 | M8 | 58 | 15~25 | 129 | 142 | 25 |

| XC110-24 | 110 | 12~28 | M6 | 45 | 12~28 | 102 | 118 | 24 |

| XC145-25 | 145 | 14~55 | M8/M6 | 72 | 14~55 | 115 | 153 | 25 |

| XC110-40 | 110 | Upon Request | M6 | 45 | 12~28 | 102 | 118 | 40 |

| XC100-43 | 100 | Upon Request | M8 | 58 | 15~25 | 129 | 142 | 44 |

| XC145-60 | 145 | Upon Request | M8/M6 | 72 | 14~55 | 115 | 153 | 60 |

| XC120-84 | 120 | Upon Request | M8 | 70 | 15~30 | 137 | 165 | 84 |

| XC145-95 | 145 | Upon Request | M8/M6 | 72 | 14~55 | 115 | 153 | 95 |

| XC170-100 | 170 | Upon Request | M10/M6 | 90 | 20~70 | 139 | 178 | 100 |

| XC170-145 | 170 | Upon Request | M10/M6 | 90 | 20~70 | 139 | 178 | 145 |

| XC170-200 | 170 | Upon Request | M10/M6 | 90 | 20~70 | 139 | 178 | 200 |

| XC198-210 | 198 | Upon Request | M12/M6 | 110 | 24~90 | 170 | 218 | 210 |

| XC198-285 | 198 | Upon Request | M12/M6 | 110 | 24~90 | 170 | 218 | 285 |

| XC198-370 | 198 | Upon Request | M12/M6 | 110 | 24~90 | 170 | 218 | 370 |

| XC232-430 | 232 | Upon Request | M16/M6 | 130 | 38~90 | 180 | 278 | 430 |

| XC232-550 | 232 | Upon Request | M16/M6 | 130 | 38~90 | 180 | 278 | 550 |

| XC287-670 | 287 | Upon Request | M16/M6 | 165 | 38~90 | 183 | 315 | 670 |

| XC287-820 | 287 | Upon Request | M16/M6 | 165 | 38~90 | 183 | 315 | 820 |

| XC287-1000 | 287 | Upon Request | M16/M6 | 165 | 38~90 | 183 | 315 | 1,000 |

| XC298-1260 | 298.5 | Upon Request | M10/G1 | 246 | 65~95 | 277 | 345 | 1,260 |

| XC298-1580 | 298.5 | Upon Request | M10/G1 | 246 | 65~95 | 277 | 345 | 1,580 |

| PN | D (in) | ΦC (in) | M | B (in) | ΦA (in) | L (in) | F (in) | Torque NORMAL [in.lbs] |

|---|---|---|---|---|---|---|---|---|

| XC45-1 | 1.8 | 0.2 ~ 0.7 | M4 | 1.1 | 0.2 ~ 0.6 | 2.6 | 2.6 | 8.9 |

| XC45-2 | 1.8 | 0.2 ~ 0.7 | M4 | 1.1 | 0.2 ~ 0.6 | 2.6 | 2.6 | 17.7 |

| XC60-3 | 2.4 | 0.5 ~ 0.9 | M5 | 1.4 | 0.3 ~ 0.7 | 3.1 | 3.5 | 26.6 |

| XC69-3 | 2.7 | 0.2 ~ 0.7 | M4/M5 | 1.1 | 0.3 ~ 0.6 | 2.7 | 3.1 | 26.6 |

| XC60-5 | 2.4 | 0.5 ~ 0.9 | M5 | 1.4 | 0.3 ~ 0.7 | 3.1 | 3.5 | 44.3 |

| XC80-8 | 3.1 | 0.6 ~ 1.1 | M6 | 1.9 | 0.4 ~ 0.8 | 3.5 | 4.5 | 70.8 |

| XC94-7 | 3.7 | 0.4 ~ 1.1 | M5/M6 | 1.4 | 0.5 ~ 0.9 | 3.2 | 3.5 | 62 |

| XC110-10 | 4.3 | 0.5 ~ 1.1 | M6 | 1.8 | 0.5 ~ 1.1 | 4 | 4.6 | 88.5 |

| XC80-11 | 3.1 | 0.6 ~ 1.1 | M6 | 1.9 | 0.4 ~ 0.8 | 3.5 | 4.5 | 97.4 |

| XC90-15 | 3.5 | 0.6 ~ 1.1 | M6 | 1.9 | 0.4 ~ 0.8 | 3.5 | 4.5 | 132.8 |

| XC94-14 | 3.7 | 0.4 ~ 1.5 | M5/M8 | 1.4 | 0.5 ~ 0.9 | 4.3 | 3.5 | 123.9 |

| XC100-25 | 3.9 | 0.4 ~ 1.5 | M8 | 2.3 | 0.6 ~ 1.0 | 5.1 | 5.6 | 221.3 |

| XC110-24 | 4.3 | 0.5 ~ 1.1 | M6 | 1.8 | 0.5 ~ 1.1 | 4 | 4.6 | 212.4 |

| XC145-25 | 5.7 | 0.6 ~ 2.2 | M8/M6 | 2.8 | 0.6 ~ 2.2 | 4.5 | 6 | 221.3 |

| XC110-40 | 4.3 | Upon Request | M6 | 1.8 | 0.5 ~ 1.1 | 4 | 4.6 | 354 |

| XC100-43 | 3.9 | Upon Request | M8 | 2.3 | 0.6 ~ 1.0 | 5.1 | 5.6 | 389.4 |

| XC145-60 | 5.7 | Upon Request | M8/M6 | 2.8 | 0.6 ~ 2.2 | 4.5 | 6 | 531 |

| XC120-84 | 4.7 | Upon Request | M8 | 2.8 | 0.6 ~ 1.2 | 5.4 | 6.5 | 743.5 |

| XC145-95 | 5.7 | Upon Request | M8/M6 | 2.8 | 0.6 ~ 2.2 | 4.5 | 6 | 840.8 |

| XC170-100 | 6.7 | Upon Request | M10/M6 | 3.5 | 0.8 ~ 2.8 | 5.5 | 7 | 885.1 |

| XC170-145 | 6.7 | Upon Request | M10/M6 | 3.5 | 0.8 ~ 2.8 | 5.5 | 7 | 1283.4 |

| XC170-200 | 6.7 | Upon Request | M10/M6 | 3.5 | 0.8 ~ 2.8 | 5.5 | 7 | 1770.1 |

| XC198-210 | 7.8 | Upon Request | M12/M6 | 4.3 | 0.9 ~ 3.5 | 6.7 | 8.6 | 1858.7 |

| XC198-285 | 7.8 | Upon Request | M12/M6 | 4.3 | 0.9 ~ 3.5 | 6.7 | 8.6 | 2522.5 |

| XC198-370 | 7.8 | Upon Request | M12/M6 | 4.3 | 0.9 ~ 3.5 | 6.7 | 8.6 | 3274.8 |

| XC232-430 | 9.1 | Upon Request | M16/M6 | 5.1 | 1.5 ~ 3.5 | 7.1 | 10.9 | 3805.8 |

| XC232-550 | 9.1 | Upon Request | M16/M6 | 5.1 | 1.5 ~ 3.5 | 7.1 | 10.9 | 4867.9 |

| XC287-670 | 11.3 | Upon Request | M16/M6 | 6.5 | 1.5 ~ 3.5 | 7.2 | 12.4 | 5930 |

| XC287-820 | 11.3 | Upon Request | M16/M6 | 6.5 | 1.5 ~ 3.5 | 7.2 | 12.4 | 7257.6 |

| XC287-1000 | 11.3 | Upon Request | M16/M6 | 6.5 | 1.5 ~ 3.5 | 7.2 | 12.4 | 8850.7 |

| XC298-1260 | 11.8 | Upon Request | M10/G1 | 9.7 | 2.6 ~ 3.7 | 10.9 | 13.6 | 11151.9 |

| XC298-1580 | 11.8 | Upon Request | M10/G1 | 9.7 | 2.6 ~ 3.7 | 10.9 | 13.6 | 13984.2 |

Note:

Design Options: Table values are for proven designs. We can also make custom designs from your drawings. We can provide a free evaluation service for your drawings.

Standard Tolerances: Bore tolerance is standard H7. Keyway tolerance is standard JS9E.

Material Choices:

- Standard: Stainless Steel 304 (housing), Neodymium Iron Boron (magnets).

- Other options available: Stainless Steel 316L, 431, Carbon Steel (housing); Sm2Co17 (magnets).

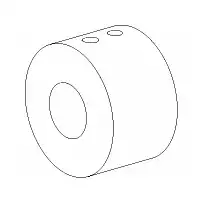

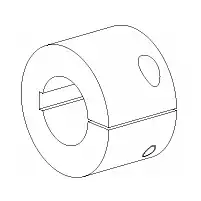

High Torque Connection: For torque above 40 N.m, the outer rotor uses a flange connection. The 'C' value in the table should be less than or equal to the outer rotor's inner diameter.

Screw Sizes: The 'M' column shows screw size. Inner rotors typically use smaller screws; outer rotors and shrouds use larger screws.

Testing: Third-party torque and material test reports are available.

High temperature custom options: CCmagnetics can customize Samarium Cobalt magnetic couplers. They have a torque range of 20 to 1,290 N.m (177 to 11,417 in.lbs) and can withstand high temperatures up to 280°C (536°F).

Ordering & Delivery: No minimum order quantity (MOQ). Global door-to-door delivery is available.

Shaft Customization: You can choose the shaft size and shape (Free Service).

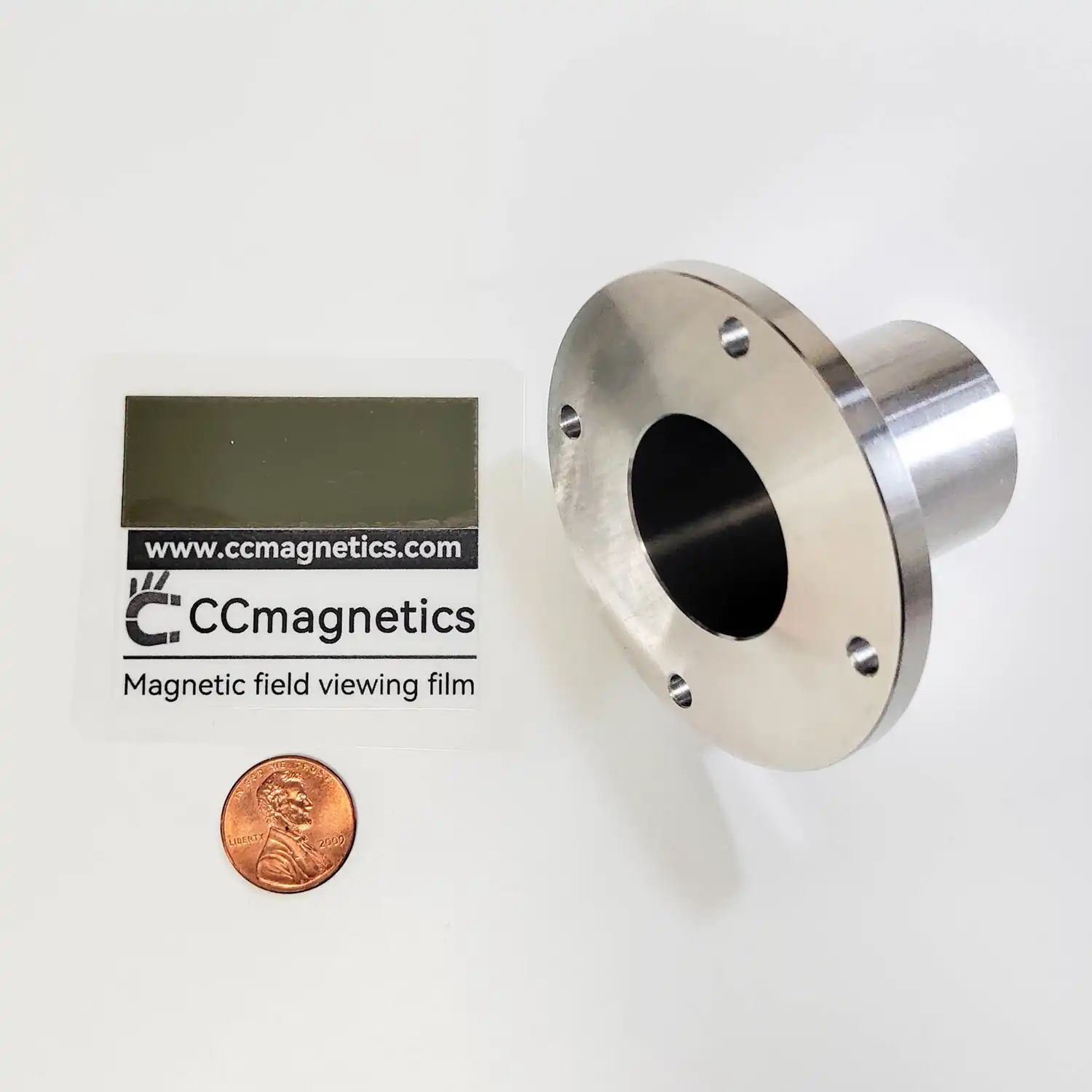

Containment Shroud: Optional.

Shaft fixing method

Magnetic disc vs co-axial coupling comparison

| Magnetic disc vs co-Axial coupling comparison |

|

|

|---|---|---|

| Coupling style | Magnetic disc couplings ( XD ) | Co-axial magnetic couplings ( XC ) |

| Permanent-magnetic | √ | √ |

| Contactless | √ | √ |

| Maintenance-free | √ | √ |

| Torsionally flexible | √ | √ |

| Low vibrations | √ | √ |

| Material | Standard: SS304. Options: Aluminum alloy 6061,Stainless steel 316L,PVC, available) |

Standard: SS304. Options: SS316/UNS S31603. |

| Containment shroud | None | Optional |

| Axial forces | High axial force which must be restrained | Coupling finds its own center with ~0 axial force |

| Shaft fixing method | Small size type A, big size type B & C available |

Type B |

| Slip torque adjustment | Air gap can be adjusted to increase or decrease slip torque |

Coupling hubs can be seperated axially to decrease slip torque (axial force will result) |

| Angular misalignment capacity | 3° Max | Ensure coupling hubs (or barrier if used) do not contact |

| Parallel misalignment capacity | 6.35mm (0.25in) Max | Ensure coupling hubs (or barrier if used) do not contact |

| Containment barrier | Simple flat barrier | Top-hat shaped barrier |

| Max. pressure resistance [bar] | Up to 80 bars depending on size | Up to 90 bars depending on size |

| Max. temperature resistance [°C] | 150/300 depending on magnet material | 150/300 depending on magnet material |

Please Note:

- The magnetic coupling pump containment shroud is optional, we can produce it according to your drawings, the larger the order quantity, the better the discount.

- We are the original manufacturer for magnetic coupling pump, we provide very flexible customizability; any grade of magnet, any material, one-year warranty, lifetime technical support.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

Reviews

There are no reviews yet.