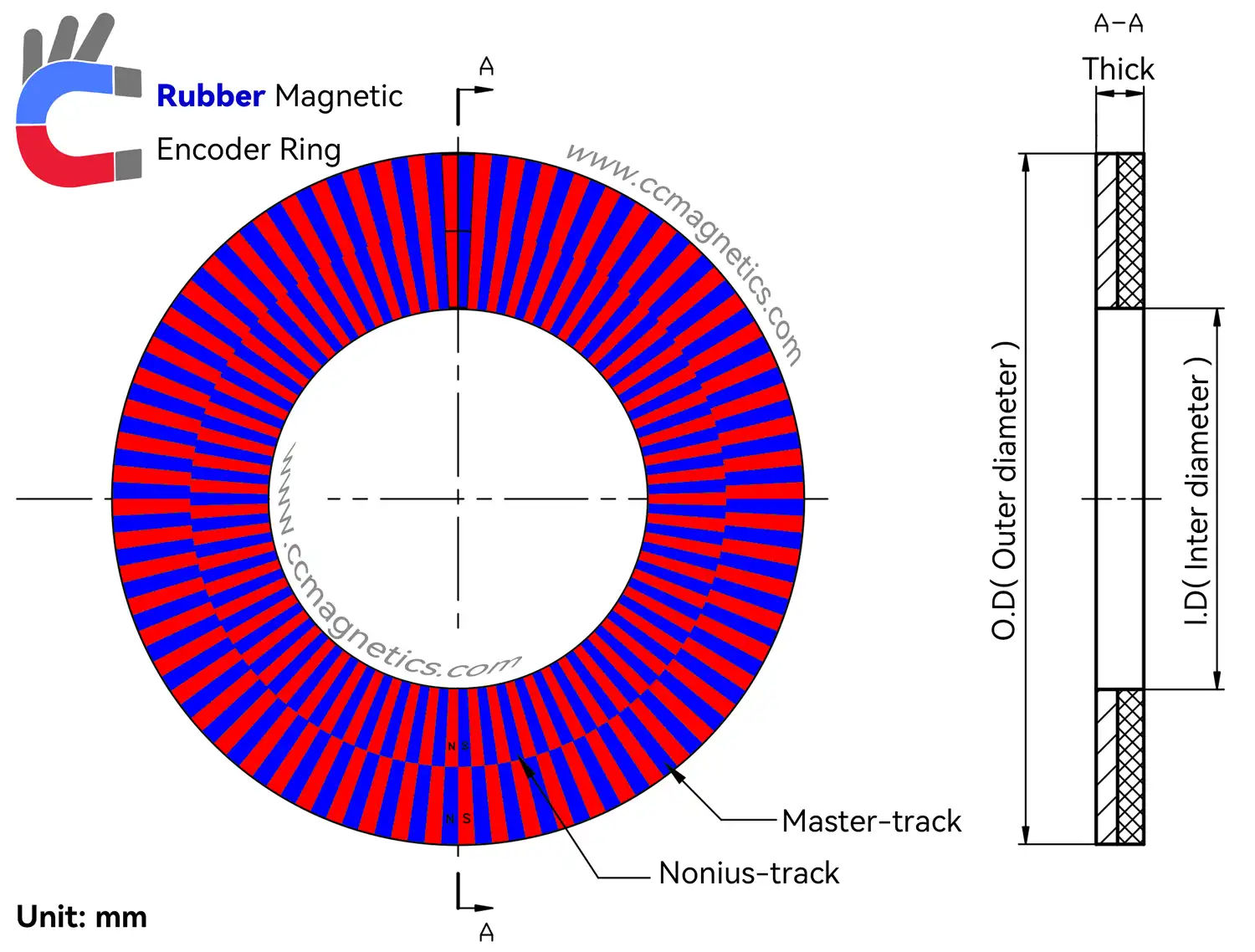

How Nonius Magnet Rings Works ?

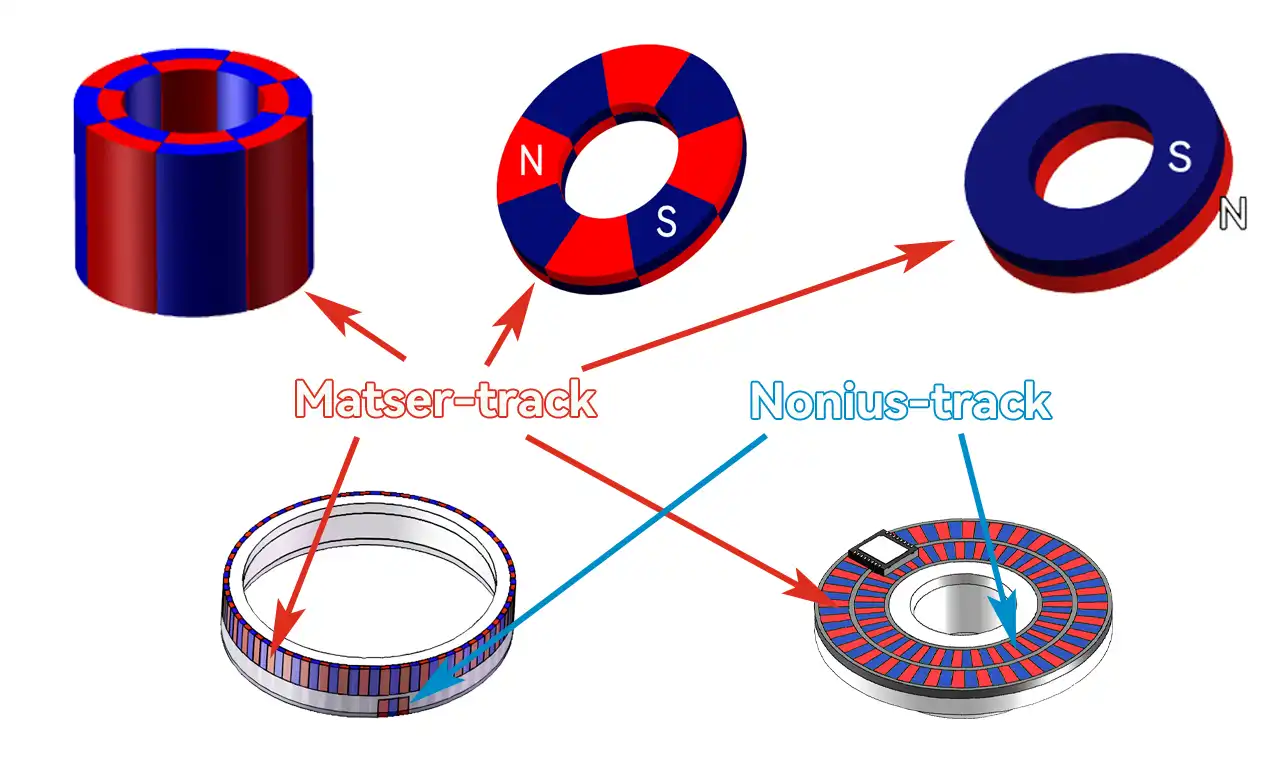

Our axial magnet rings utilize a sophisticated Dual-Track Magnetic System on a flat surface to achieve absolute positioning:

- Master Track: Contains an even number of magnetized pole pairs for high-precision incremental signals.

- Nonius Track: Contains one less pole pair than the Master track.

By calculating the offset between these two tracks, the sensor (such as iC-Haus chips) generates an absolute position value instantly upon power-up, without the need for a reference run.

Available Models (Stock List)

We stock the following part numbers. These are standard parts fully compatible with existing HUT series specifications.

🔹 Compact Series (OD: 29mm)

Compatible with iC-MU / iC-MU128

- HUT128A32 (31/32 Pole Pairs) – In Stock

- HUT128A64 (63/64 Pole Pairs) – In Stock

🔹 Standard Industrial Series (OD: 34.5mm - 65.1mm)

Compatible with iC-MU150

- HUT150A32 (31/32 Pole Pairs) – In Stock

- HUT150A64 (63/64 Pole Pairs) – In Stock

🔹 Large Bore/High Res Series (OD: 44.5mm - 85mm)

Compatible with iC-MU200

- HUT200A16 (15/16 Pole Pairs) – In Stock

- HUT200A32 (31/32 Pole Pairs) – In Stock

- HUT200A64 (63/64 Pole Pairs) – In Stock

- HUT220A32 (31/32 Pole Pairs) – In Stock

(Note: Please refer to our downloadable datasheet for detailed dimensions, ID/OD, and pole width specifications for each model.)

| SKU | O.D (mm) | I.D (mm) | T (mm) | MT | NT | MATL | SF | MAG | CMTS |

|---|---|---|---|---|---|---|---|---|---|

| R0713 | 27.2 | 15 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150 and includes metal carrier compatible with mu128. |

| R0871 | 29 | 15 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU, Datasheet.HUT128A32 and AKP18. |

| R0661 | 29 | 10 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU (32-pole master-track, 31-pole nonius-track, drawings via sales) and AKS16. |

| R0872 | 28.5 | 16.5 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU, Datasheet.ic-MU (32-pole master-track, 31-pole nonius-track, drawings via sales) and AKS16-MT. |

| R0662 | 29 | 15 | 2.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU (32-pole master-track, 31-pole nonius-track, drawings available via sales) and AKP18. |

| R0873 | 30 | 11 | 3 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU (32-pole pairs in master-track, 31-pole pairs in nonius-track; drawings available via sales), MU18S_30-32N and AKS16.,Datasheet. |

| R0814 | 56 | 38 | 1.1 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU, HUT128A64 and AKP18., Datasheet. |

| R0868 | 54.7 | 40 | 1.1 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | MU128 is compatible with AKP18. |

| R0811 | 56 | 35 | 2 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU (64-pole master-track, 63-pole nonius-track, drawings via sales) and AKS16-MT. |

| R0801 | 54.7 | 40 | 2 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU, ic-MU (64-pole master-track, 63-pole nonius-track, drawings via sales) and AKS16-MT. |

| R0812 | 55 | 35 | 2.5 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with MU128, includes metal carrier and compatible with AKS16. |

| R0866 | 53 | 40 | 3.5 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU and AKS16, Datasheet. |

| R0815 | 56 | 37 | 13 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with MU128, mu35s_56-64n, includes metal carrier and is compatible with AKS16-MT. |

| R0874 | 18 | 8 | 2 | 32 | 30 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150 and AKS16, Datasheet. |

| R0875 | 20 | 7 | 2 | 32 | 30 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, Datasheet. and AKP18. |

| R0714 | 34 | 18 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, HUT150A32 and AKS16, Datasheet. |

| R0684 | 31.5 | 19.5 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with AKS16 and MU150, Datasheet. |

| R0702 | 33 | 20 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, includes metal carrier and compatible with mu150 and AKS16-MT. |

| R0704 | 35 | 23 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, includes metal carrier and compatible with mu150 and AKP18. |

| R0839 | 31.5 | 19.5 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Metal carrier included, mu150 |

| R0703 | 33 | 20 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | 58825、Compatible with ic-MU150, Datasheet. and AKS16. |

| R0877 | 39 | 20 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150 (32-pole master-track, 31-pole nonius-track, drawings via sales) and AKS16-MT. |

| R0721 | 35 | 23 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150 and AKS16, Datasheet. |

| R0841 | 34 | 18 | 5 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Metal carrier included, mu150 |

| R0712 | 34 | 20 | 11 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, includes metal carrier and compatible with mu150 and AKP18. |

| R0878 | 64 | 47.4 | 1.1 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, AKS16-MT, HUT150A64, Datasheet. |

| R0828 | 64 | 45 | 5 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with IC-MU150, includes a metal carrier with MU150, and compatible with AKS16-MT. |

| R0879 | 63 | 46 | 2 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150 (64-pole master-track, 63-pole nonius-track, drawings via sales) and AKS16. |

| R0829 | 64 | 45 | 2.5 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150, 58834, ic-MU150 (64-pole master-track, 63-pole nonius-track, drawings via sales) and AKS16. |

| R0838 | 68 | 55 | 3.5 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU150 (64-pole master-track, 63-pole nonius-track, drawings via sales) and AKS16. |

| R0529 | 22 | 6 | 2 | 32 | 30 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 (16-pole pairs master-track, 15-pole pairs nonius-track, drawings available via sales) and AKS16-MT. |

| R0880 | 22 | 8 | 2 | 32 | 30 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 (16-pole pairs master-track, 15-pole pairs nonius-track, drawings available via sales) and AKS16-MT. |

| R0881 | 22 | 10 | 2 | 32 | 30 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 (16-pole pairs in master-track, 15-pole pairs in nonius-track, drawings available via sales) and AKS16. |

| R0882 | 25 | 11.5 | 2 | 32 | 30 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 (16-pole pairs master-track, 15-pole pairs nonius-track, drawings available via sales) and AKP18. |

| R0763 | 42 | 29 | 1.1 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with mu200; includes metal carrier, compatible with mu200 and AKS16-MT. |

| R0762 | 44.5 | 25 | 1.4 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | HUT200A32 includes metal carrier and is compatible with AKP18. |

| R0759 | 48 | 37.7 | 1.5 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | The mu37s 45-32n includes a metal bracket and is compatible with MU200 and AKS16-MT. |

| R0794 | 49 | 25 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-mu200. R0794: full hole, R0758: half hole |

| R0758 | 49 | 25 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 (32-pole pairs master-track, 31-pole pairs nonius-track, drawings available via sales) and AKP18. |

| R0752 | 42.5 | 30.5 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 and AKS16-MT, Datasheet. |

| R0883 | 49 | 25 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200, HUT220A32 and AKS16; Datasheet. |

| R0774 | 48 | 35 | 2 | 64 | 62 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 and AKS16, Datasheet. |

| R0852 | 84 | 62 | 1.8 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200, 58843, HUT200A64, AKS16-MT, Datasheet. |

| R0851 | 84 | 65 | 2.5 | 128 | 126 | Vulcanized rubber magnet material | 20-30mT | Axial | Compatible with ic-MU200 and AKP18, Datasheet. |

Note:

All dimensions in the table are in millimeters.

Abbreviations:

- MT (Master-track): Both regular and incremental magnetic rings have poles on this track. '10 poles' means 5 pole pairs.

- NT (Nonius-track): This is usually the second track on absolute encoder rings where poles are located.

- MATL: material

- MAG: magnetization method

- SF: surface magnetic field

- CMTS: comments

Please contact our sales team for drawings and photos.

If the SKU number is clickable, you can download the datasheet directly.

Target Applications

These axial magnetic rings are the preferred choice for:

- 🤖 Robotics: Joint control in collaborative robots (Cobots).

- 🏥 Medical Technology: Precision positioning for surgical robots and MRI tables.

- 🏭 Motor Feedback: Brushless DC motor commutation and speed control.

Why Choose Our Axial Magnet Rings?

1. Ultra-Thin Design for Compact Housing

Space is at a premium in modern motor feedback systems. Our axial rings feature an incredibly slim profile (Total thickness: 1.10 mm), allowing for:

- Downsized motor housings.

- Integration into slim robotic joints.

- Reduced rotational inertia.

2. Superior Material Construction

We use a Magnetic Vulcanized Rubber Compound bonded securely to a Stainless Steel Insert.

- High-Speed Stability: The vulcanization process ensures optimum rubber-metal adhesion, preventing detachment even at high rotational speeds.

- Durability: Excellent resistance to industrial oils, grease, dust, and vibration.

- Temperature Resilience: Fully operational from -40°C to +140°C.

3. Verified Sensor Compatibility

Our stock items are strictly verified for compatibility with industry-standard Hall effect sensors, specifically the iC-MU Series:

- Supported Chips: iC-MU, iC-MU150, iC-MU200.

- Signal Quality: Optimized magnetic field strength ensures a clean signal with the recommended 0.40 mm mechanical air gap.

FAQs

Please send the SKU number and quantity of the magnetic rings you want from the list.

Your salesperson will send you a price quote and payment options (T/T 100% upfront or credit card 100% upfront).

- In-stock items: Ship immediately after payment.

- Out-of-stock items: Ship within 30 days after payment.

Our magnetic rings have a key benefit: transparent costs for molds and magnetizing coils. We don't charge extra for these.

For small sample orders (around 10 pieces), this stock is usually leftover from larger production runs. Please pay quickly to secure your stock. We don't start production for small orders; it's not cost-effective for us.

We usually start production for orders over 2k-10k pieces to manage costs. If your order is small and not confirmed quickly, you might miss out on current stock.

Sizes: All lengths are in millimeters (mm) by default.

Number of poles:

- The Master-track refers to the main magnetic track's pole count on a ring magnet. Most ring magnets, like those for motors or incremental encoders, have only one magnetic track.

- However, absolute encoder ring magnets or encoder ring magnets with marker points also have a Nonius-track. This means they have two magnetic tracks, as shown in the picture.

- Ferrite magnets are also called sintered ferrite or hard ferrite magnets. They look and are made like ceramics, so some call them ceramic magnets.These magnets are cheap to make in large amounts, even though the mold costs are high. They are very good at resisting rust and high temperatures, up to 250℃.Ferrite magnets are accurate and low-cost for encoders. But, they can break easily if shaken a lot, like in outdoor robots. For those, Vulcanized rubber magnet material is more stable.

- Injection molded ferrite magnets are made by mixing ferrite magnetic powder with plastic binders like Nylon (PA6 or 12) or PPS. This mixture is then injection molded, meaning it's shaped using a mold.These magnets can even be molded directly onto a metal shaft. They can work in temperatures up to 150°C.

Bonded neodymium magnets are made by mixing neodymium magnetic powder with a binder.

Simply put, they are injection molded, which means they contain a binder. About 80% of the magnet is neodymium powder, and the remaining 20% is binder.

Their benefits include high dimensional accuracy, great design flexibility, and good mechanical strength.

Injection molded neodymium magnets are made by mixing neodymium magnetic powder with thermoplastic. This mix is then injection molded. These magnets are stronger than injection molded ferrite magnets.

Injection molded neodymium magnets can be made into many shapes. They can be small or irregular. You can magnetize them with multiple poles or complex patterns. They are also very accurate and consistent in shape.

These magnets can be molded directly onto motor cores or metal shafts. This saves assembly costs. They are seen as a stronger option than injection molded ferrite magnets. They can work in temperatures up to 180℃.

These magnets are injection molded neodymium or ferrite magnets that include a metal carrier. Please see the picture below:

These magnets are injection molded neodymium or ferrite magnets that include a metal carrier. Please see the picture below:

Sintered NdFeB magnets are also called Sintered Neodymium magnets. These are the strongest known permanent magnets. They are made from neodymium (Nd), iron (Fe), boron (B), and other rare earth elements.

These magnets create very strong magnetic fields and stay magnetic at room temperature. They can be made into many shapes. This makes them great for many uses, especially for high-end commercial motors.

Sintering is how they are made. Powdered materials are heated until they merge. This process makes the magnets stronger and more effective.

However, these magnets can corrode easily and are affected by high temperatures. So, they are usually coated (often with a nickel-copper-nickel layer) to protect them. Adding heavy rare earth elements also helps them resist higher temperatures.

- Vulcanized rubber magnet material is made when magnetic powder is added to rubber during a process called vulcanization. This process changes the rubber's structure, making it much stronger, more elastic, and more stable.Vulcanized rubber magnets are often used for magnetic targets on sports robots. They are flexible and don't break easily from shocks.

- Rubber magnets are made from magnetic powder mixed with synthetic rubber. They are formed by extrusion, calendering, or injection molding. You can make them into strips, rolls, sheets, blocks, rings, and many other shapes. Their main advantages are that they are flexible and can be made into various shapes.However, their disadvantage is that they are not very strong (they don't have high remanence) compared to Neodymium magnets. For encoders, regular rubber magnets can't meet high precision needs. They are only good for single-track incremental encoders.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

gissendannerdetrick –

Toller Service und qualitativ hochwertige Produkte.

jgroenert –

thank you.