Incremental Encoder Magnets, Multipole Rotary Encoder Magnets, Incremental Rotary Magnetic Scale, Multi-pole Magnetized Target Wheel, Hard Ferrite Ring Multi-pole Magnets, Non-contact Rotary Position Measurement, Multi-pole Permanent Magnet Target Wheel, High-Accuracy Multipole Ring Sensor Magnet, Multipolar Sensor Magnets for Encoder Rotary, IC Incremental Rotary Encoder Multipole Rings Magnet

No unnecessary moulding fees

Global door-to-door delivery

Pre-delivery testing ensures accuracy

Zero mold fees. Worldwide shipping. Dedicated service. Find what you need and enjoy the process.

At ccmagnetics, we provide free access to our extensive mold inventory, helping you save both time and money. Our commitment is to help you find the perfect magnetic ring for your needs. For magnetic ring drawings or photos, please contact our sales team.

Description:

CCmagnetics has molds and magnetizing fixtures that can produce more than 400 kinds of Axial Incremental Magnetic Rings, including: Axial Incremental Magnetic Rings are made of Injection molded neodymium magnets, Ferrite magnets, Injection molded ferrite magnets, Bonded neodymium magnets, Injection molded NdFeB magnets, Injection molded ferrite magnets, NdFeB plastic coating, with pole numbers ranging from 2 poles to 128 poles. If you can't find the Axial Incremental Magnetic Rings you need, please contact our sales staff.

Specification:

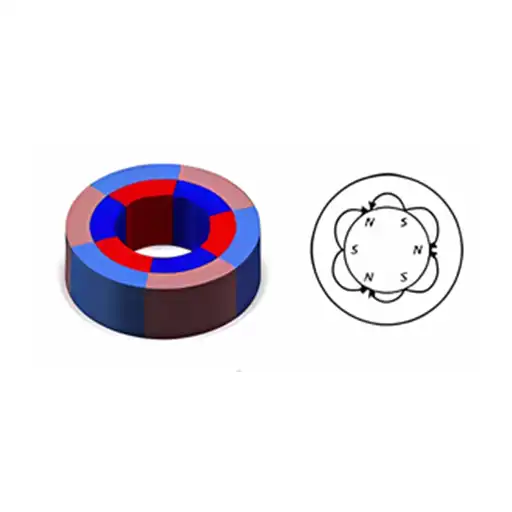

Magnetization method

(Ex. MT/Pole Count = 8 poles)

(Ex. MT/Pole Count = 2 poles)

(Ex. MT/Pole Count = 6 poles)

| SKU | O.D (mm) | I.D (mm) | T (mm) | MT | MATL | SF | MAG | CMTS |

|---|---|---|---|---|---|---|---|---|

| R0002 | 3 | 0 | 3 | 2 | Injection molded ferrite magnets | 300-330mT | Axial | Magnetic Encoder Disc |

| R0020 | 7.8 | 3 | 2 | 3 | Injection molded ferrite magnets | 80mT | Axial | |

| R0040 | 8.9 | 3.2 | 4.2 | 6 | Injection molded neodymium magnets | 110-125mT | Axial | Magnetic encoder ring |

| R0050 | 9.5 | 2 | 2 | 6 | Injection molded ferrite magnets | 55mT | Axial | |

| R0051 | 9.5 | 2 | 2 | 4 | Injection molded ferrite magnets | 70mT | Axial | |

| R0886 | 9.5 | 1 | 2 | 6 | Bonded neodymium magnets | 85-100mT | Axial | |

| R0058 | 9.6 | 1 | 2 | 6 | Injection molded ferrite magnets | 55mT | Axial | |

| R0060 | 10 | 2.2 | 2 | 2 | Injection molded ferrite magnets | 95-105mT | Axial | Magnetic encoder ring |

| R0061 | 10 | 2.2 | 2 | 6 | Injection molded ferrite magnets | 95-105mT | Axial | Magnetic encoder ring |

| R0064 | 10 | 2.3 | 2 | 6 | Injection molded ferrite magnets | 60mT | Axial | |

| R0084 | 11.5 | 2.3 | 3.5 | 2 | Injection molded ferrite magnets | 80mT | Axial | |

| R0110 | 13 | 1.5 | 3 | 4 | Injection molded ferrite magnets | 75mT | Axial | |

| R0112 | 13 | 1.5 | 3 | 8 | Injection molded ferrite magnets | 20mT | Axial | |

| R0111 | 13 | 1.5 | 3 | 6 | Injection molded ferrite magnets | 75mT | Axial | |

| R0113 | 13 | 1.5 | 3 | 14 | Injection molded ferrite magnets | 30mT | Axial | |

| R0114 | 13 | 1.5 | 3 | 22 | Injection molded ferrite magnets | 100mT | Axial | |

| R0122 | 13.3 | 2 | 2.1 | 2 | Bonded neodymium magnets | 220-230mT | Axial | Magnetic encoder ring |

| R0143 | 14 | 3.2 | 4 | 6 | Injection molded neodymium magnets | 90-100mT | Axial | Magnetic encoder ring |

| R0151 | 14 | 1.5 | 2.3 | 6 | Injection molded neodymium magnets | 110-120mT | Axial | Magnetic encoder ring |

| R0152 | 14 | 2 | 2.3 | 6 | Injection molded neodymium magnets | 110-120mT | Axial | Magnetic encoder ring |

| R0213 | 14 | 1.98 | 2 | 20 | Injection molded ferrite magnets | 60mT | Axial | |

| R0220 | 14 | 2 | 2 | 6 | Injection molded ferrite magnets | 75mT | Axial | |

| R0219 | 14 | 2 | 2 | 4 | Injection molded ferrite magnets | 75mT | Axial | |

| R0222 | 14 | 2 | 2 | 14 | Injection molded ferrite magnets | 75mT | Axial | |

| R0221 | 14 | 2 | 2 | 8 | Injection molded ferrite magnets | 75mT | Axial | |

| R0315 | 14.5 | 2.3 | 4 | 8 | Injection molded ferrite magnets | 110mT | Axial | |

| R0313 | 14.5 | 2.3 | 4 | 4 | Injection molded ferrite magnets | 110mT | Axial | |

| R0314 | 14.5 | 2.3 | 4 | 6 | Injection molded ferrite magnets | 110mT | Axial | |

| R0311 | 14.5 | 3.175 | 2 | 6 | Injection molded ferrite magnets | 90mT | Axial | |

| R0312 | 14.5 | 3.175 | 2 | 8 | Injection molded ferrite magnets | 90mT | Axial | |

| R0310 | 14.5 | 3.175 | 4 | 6 | Injection molded ferrite magnets | 55-100mT | Axial | |

| R0308 | 14.5 | 3.175 | 3 | 2 | Injection molded ferrite magnets | 75mT | Axial | |

| R0309 | 14.5 | 3.175 | 4 | 4 | Injection molded ferrite magnets | 55-100mT | Axial | |

| R0306 | 14.5 | 4 | 3 | 2 | Injection molded ferrite magnets | 90mT | Axial | |

| R0304 | 14.5 | 3.175 | 2 | 4 | Injection molded ferrite magnets | 90mT | Axial | The inside of the magnetic ring is made of copper. |

| R0303 | 14.5 | 3.175 | 4 | 24 | Injection molded ferrite magnets | 55-100mT | Axial | |

| R0305 | 14.5 | 3.175 | 2 | 4 | Injection molded ferrite magnets | 90mT | Axial | |

| R0302 | 14.5 | 3.175 | 4 | 8 | Injection molded ferrite magnets | 55-100mT | Axial | |

| R0301 | 14.5 | 1.5 | 2 | 8 | Injection molded ferrite magnets | 75mT | Axial | |

| R0316 | 14.6 | 3.17 | 3 | 6 | Injection molded ferrite magnets | 75mT | Axial | Double Face both had magnetic poles |

| R0363 | 15.5 | 3.15 | 3 | 10 | Injection molded neodymium magnets | 130mT | Axial | |

| R0362 | 15.5 | 3.15 | 3 | 6 | Injection molded neodymium magnets | 130mT | Axial | |

| R0361 | 15.5 | 3.15 | 3 | 4 | Injection molded neodymium magnets | 130mT | Axial | |

| R0916 | 15.9 | 2.3 | 2.7 | 6 | Injection molded ferrite magnets | 90-110mT | Axial | O.D tolerance: ±0.05mm/ I.D tolerance: ±0.02mm/ Height (thickness) tolerance:±0.10mm |

| R0375 | 16 | 3.17 | 4 | 10 | Injection molded ferrite magnets | 100mT | Axial | |

| R0376 | 16 | 3.17 | 2.5 | 6 | Injection molded ferrite magnets | 100mT | Axial | |

| R0374 | 16 | 3.17 | 4 | 8 | Injection molded ferrite magnets | 100mT | Axial | |

| R0373 | 16 | 3.17 | 4 | 6 | Injection molded ferrite magnets | 100mT | Axial | |

| R0371 | 16 | 3.2 | 5 | 10 | Injection molded ferrite magnets | 55-60mT | Axial | Magnetic encoder ring |

| R0398 | 16.7 | 4 | 5 | 4 | Injection molded ferrite magnets | 100mT | Axial | |

| R0402 | 17 | 5 | 4.5 | 4 | Injection molded ferrite magnets | 135mT | Axial | |

| R0453 | 18 | 10 | 5 | 4 | Sintered neodymium magnets | 200-400mT | Axial | |

| R0450 | 18 | 10 | 5 | 4 | Sintered NdFeB Magnets | 270-275mT | Axial | |

| R0429 | 18 | 2.3 | 4 | 8 | Injection molded ferrite magnets | 75mT | Axial | |

| R0425 | 18 | 2 | 4 | 24 | Injection molded neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0422 | 18 | 2.3 | 4 | 10 | Injection molded neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0420 | 18 | 2.3 | 4 | 6 | Injection molded neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0421 | 18 | 2.3 | 4 | 8 | Injection molded neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0418 | 18 | 3.2 | 3.6 | 24 | Injection molded neodymium magnets | 60-63mT | Axial | Magnetic encoder ring |

| R0417 | 18 | 3.2 | 3.6 | 10 | Injection molded neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0416 | 18 | 3.2 | 3.6 | 8 | Injection molded neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0921 | 18.1 | 2.26 | 3.2 | 32 | Injection molded ferrite magnets | 40-90mT | Axial | O.D tolerance: ±0.05mm/ I.D tolerance: ±0.02mm/ Height (thickness) tolerance:±0.10mm |

| R0920 | 18.1 | 2.26 | 3.2 | 24 | Injection molded ferrite magnets | 40-90mT | Axial | O.D tolerance: ±0.05mm/ I.D tolerance: ±0.02mm/ Height (thickness) tolerance:±0.10mm |

| R0919 | 18.1 | 2.26 | 3.2 | 12 | Injection molded ferrite magnets | 40-90mT | Axial | O.D tolerance: ±0.05mm/ I.D tolerance: ±0.02mm/ Height (thickness) tolerance:±0.10mm |

| R0918 | 18.1 | 2.26 | 3.2 | 8 | Injection molded ferrite magnets | 40-90mT | Axial | O.D tolerance: ±0.05mm/ I.D tolerance: ±0.02mm/ Height (thickness) tolerance:±0.10mm |

| R0469 | 19 | 3.17 | 5.3 | 8 | Injection molded ferrite magnets | 120mT | Axial | |

| R0467 | 19 | 2 | 5.3 | 8 | Injection molded ferrite magnets | 120mT | Axial | |

| R0468 | 19 | 2.3 | 5.3 | 8 | Injection molded ferrite magnets | 120mT | Axial | |

| R0498 | 20 | 18 | 2 | 2 | Bonded neodymium magnets | 85-100mT | Axial | Magnetics encoder ring |

| R0496 | 20 | 2 | 2 | 2 | Injection molded ferrite magnets | 75mT | Axial | |

| R0577 | 23.9 | 6.5 | 9.3 | 6 | Injection molded ferrite magnets | 95-100mT | Axial | Magnetic encoder ring |

| R0581 | 24 | 8 | 9.5 | 6 | Injection molded ferrite magnets | 60-70mT | Axial | Hall effect sensor magnetic ring |

| R0591 | 24.95 | 12 | 7 | 4 | Injection molded ferrite magnets | 110mT | Axial | |

| R0600 | 25 | 8 | 2.5 | 24 | Injection molded ferrite magnets | 65-75mT | Axial | Hall effect sensor magnet for motor |

| R0617 | 25.5 | 17.5 | 8 | 2 | Injection molded ferrite magnets | 75mT | Axial | |

| R0644 | 27 | 12 | 7 | 4 | Injection molded ferrite magnets | 110mT | Axial | |

| R0649 | 27.5 | 13 | 7.1 | 4 | Bonded neodymium magnets | 90-300mT | Axial | |

| R0652 | 28 | 22.8 | 5 | 24 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0657 | 28.9 | 18.9 | 1.5 | 150 | Ferrite magnets | 60-65mT | Axial | robot encoder ring |

| R0665 | 30 | 8 | 5 | 6 | Injection molded neodymium magnets | 110-120mT | Axial | Speed Control Magnetic Ring for Push Rod Motor |

| R0664 | 30 | 10 | 3 | 40 | Ferrite magnets | 95-100mT | Axial | Encoder Magnet for Logistics Robot |

| R0683 | 31 | 25 | 1.5 | 62 | Neodymium magnets | 140-150mT | Axial | incremental encoder ring |

| R0923 | 31.5 | 14.3 | 4 | 6 | Injection molded ferrite magnets | 90-110mT | Axial | O.D tolerance: ±0.05mm/ I.D tolerance: ±0.05mm/ Height (thickness) tolerance:±0.10mm |

| R0992 | 32 | 24 | 1.5 | 44 | Ferrite magnets | 50-60mT | Axial | Pole pitch: 2.0mm |

| R0688 | 32 | 24 | 1.5 | 44 | Ferrite magnets | 60-65mT | Axial | robot encoder ring |

| R0689 | 32 | 24 | 1.5 | 44 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0687 | 32 | 26 | 3 | 24 | Bonded neodymium magnets | 260-270mT | Axial | Magnetic Encoder for Brushless DC Motor |

| R0731 | 36.8 | 26.8 | 1.5 | 200 | Ferrite magnets | 60-65mT | Axial | |

| R0740 | 39 | 33 | 1.5 | 64 | Neodymium magnets | 140-150mT | Axial | rotary encoder ring |

| R0744 | 40 | 30 | 1.5 | 16 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0742 | 40 | 10.1 | 3 | 10 | Injection molded ferrite magnets | 65-70mT | Axial | Magnet for 775 Motor Magnetic Encoder |

| R0749 | 42 | 28.5 | 1.45 | 128 | Ferrite magnets | 60-65mT | Axial | |

| R0870 | 42.4 | 38 | 2.5 | 24 | Bonded neodymium magnets | 85-100mT | Axial | |

| R0884 | 42.5 | 38.5 | 1.5 | 64 | Bonded neodymium magnets | 85-100mT | Axial | MHL200/AS5304A |

| R0995 | 42.5 | 38.5 | 1.5 | 128 | Neodymium magnets | 10-20mT | Axial | Pole pitch: 1.0mm |

| R0754 | 42.5 | 38.5 | 1.5 | 64 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0753 | 42.5 | 38.5 | 1.5 | 128 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0756 | 44.2 | 34.7 | 1.5 | 48 | Ferrite magnets | 60-65mT | Axial | |

| R0764 | 45 | 21.6 | 9 | 8 | Injection molded ferrite magnets | 80-90mT | Axial | Speed Measurement Magnet for Motor |

| R0768 | 45.2 | 30 | 1.5 | 48 | Ferrite magnets | 60-65mT | Axial | |

| R0980 | 45.7 | 35.8 | 1.5 | 128 | Bonded neodymium magnets | 80-95mT | Axial | The encoder magnetic ring has a pole pitch of 2mm and is available in two materials: ferrite and bonded neodymium magnets. |

| R0771 | 47 | 39 | 18.5 | 8 | Injection molded ferrite magnets | 130-140mT | Axial | Outer Rotor Magnet for Magnetic Drive Pump |

| R0775 | 48 | 35 | 3 | 16 | Bonded neodymium magnets | 85-100mT | Axial | Hall sensor magnetic ring |

| R0779 | 49 | 43.2 | 4 | 48 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0955 | 52 | 47 | 2.5 | 24 | Bonded neodymium magnets | 200mT | Axial | Used in hair dryers |

| R0077 | 52 | 47 | 2.5 | 32 | Bonded neodymium magnets | 200mT | Axial | Used in hair dryers |

| R0806 | 56 | 25 | 15 | 64 | Injection molded ferrite magnets | 60-70mT | Axial | Brushless Motor Encoder Magnet |

| R0997 | 58 | 49 | 1.5 | 40 | Neodymium magnets | 160-180mT | Axial | Pole pitch: 4.2mm |

| R0819 | 58 | 49 | 1.5 | 40 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0998 | 58.5 | 51 | 1.5 | 86 | Neodymium magnets | 60-70mT | Axial | Pole pitch: 2.0mm |

| R0821 | 58.5 | 51 | 1.5 | 86 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0822 | 60 | 56 | 2 | 128 | Neodymium magnets | 140-150mT | Axial | Magnetic encoder ring |

| R0823 | 60.8 | 45 | 10 | 96 | Injection molded neodymium magnets | 140-150mT | Axial | High Precision Motor Strong Magnet |

| R1000 | 66 | 61.3 | 2 | 100 | Neodymium magnets | 60-70mT | Axial | Pole pitch: 2.0mm |

| R0839 | 68.8 | 58 | 1.5 | 96 | Rubber magnets | 10-20mT | Axial | Metal carrier included, Also compatible with iC-MU200. |

| R0841 | 71.5 | 58.7 | 7 | 96 | Rubber magnets | 10-20mT | Axial | Metal carrier included,mu200 |

| R0850 | 82.5 | 78.5 | 3 | 60 | Injection molded neodymium magnets | 75-80mT | Axial | 60-Pole High Precision Magnetic Encoder Ring |

Glossary of Terms:

| No. | Item | Description | Notes |

|---|---|---|---|

| 1 | SKU | Stock Keeping Unit Number | This number needs to be recorded and used when submitting inquiries to CCmagnetics. |

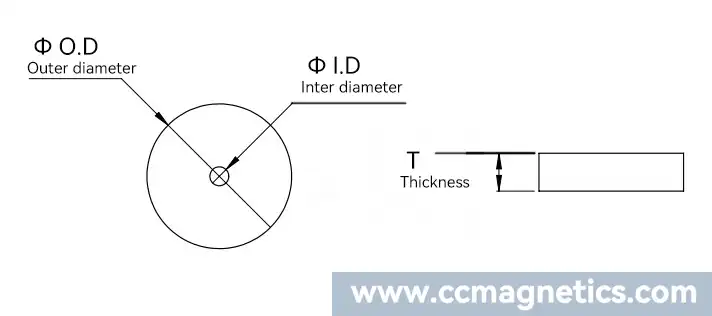

| 2, 3, 4 | O.D./I.D./T | The Magnetic Ring Dimensions | All dimensions in the table are in millimeters. O.D = Outer Diameter I.D = Inner Diameter T = Thickness |

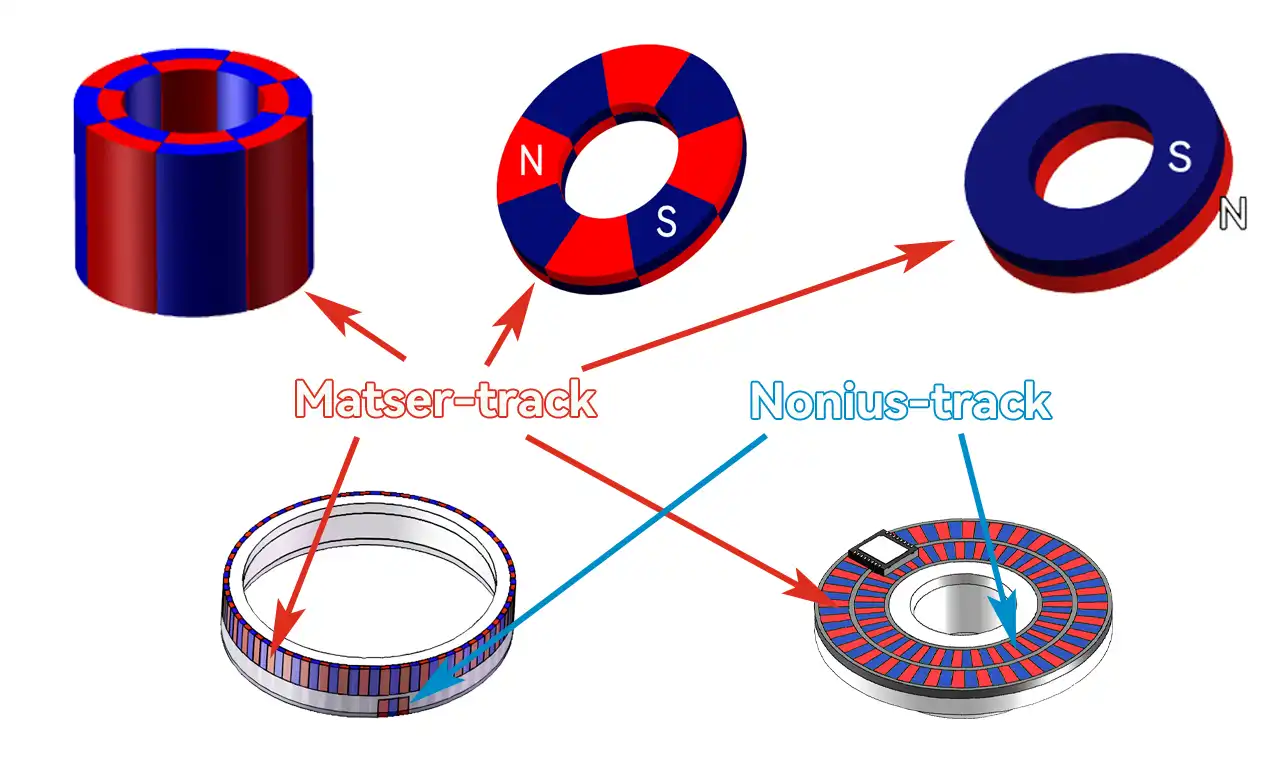

| 5 | MT | Master-track Pole Count | For a magnetic ring with a single track, the Master-track represents the number of magnetic poles. For example, "10 poles" means 5 pole pairs. |

| 6 | NT | Nonius-track: Orbit with Fewer Pole Count | For a 2-track magnetic encoder ring, the Nonius-track typically has the lower pole count. The number of poles on the Nonius-track may sometimes be an odd number, such as 3 poles. |

| 5 | MATL | Magnetic Ring Material | There are various types of magnetic ring materials. Please refer to the FAQ at the bottom of the page. |

| 6 | SF | Surface Magnetic Field | This refers to the surface magnetic field strength. |

| 7 | MAG | Magnetization Method | Common magnetization methods are listed at the top of the page. |

| 8 | CMTS | Comments | This section provides information about the use, features, and other details of the magnetic ring. |

FAQs:

Please send the SKU number and quantity of the magnetic rings you want from the list.

Your salesperson will send you a price quote and payment options (T/T 100% upfront or credit card 100% upfront).

- In-stock items: Ship immediately after payment.

- Out-of-stock items: Ship within 30 days after payment.

Our magnetic rings have a key benefit: transparent costs for molds and magnetizing coils. We don't charge extra for these.

For small sample orders (around 10 pieces), this stock is usually leftover from larger production runs. Please pay quickly to secure your stock. We don't start production for small orders; it's not cost-effective for us.

We usually start production for orders over 2k-10k pieces to manage costs. If your order is small and not confirmed quickly, you might miss out on current stock.

Sizes: All lengths are in millimeters (mm) by default.

Number of poles:

- The Master-track refers to the main magnetic track's pole count on a ring magnet. Most ring magnets, like those for motors or incremental encoders, have only one magnetic track.

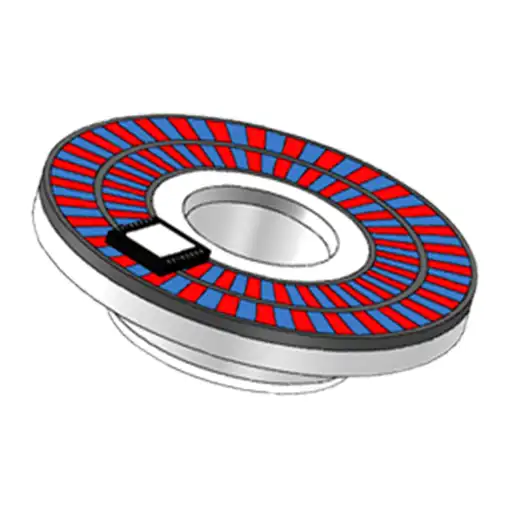

- However, absolute encoder ring magnets or encoder ring magnets with marker points also have a Nonius-track. This means they have two magnetic tracks, as shown in the picture.

- Ferrite magnets are also called sintered ferrite or hard ferrite magnets. They look and are made like ceramics, so some call them ceramic magnets.These magnets are cheap to make in large amounts, even though the mold costs are high. They are very good at resisting rust and high temperatures, up to 250℃.Ferrite magnets are accurate and low-cost for encoders. But, they can break easily if shaken a lot, like in outdoor robots. For those, Vulcanized rubber magnet material is more stable.

- Injection molded ferrite magnets are made by mixing ferrite magnetic powder with plastic binders like Nylon (PA6 or 12) or PPS. This mixture is then injection molded, meaning it's shaped using a mold.These magnets can even be molded directly onto a metal shaft. They can work in temperatures up to 150°C.

Bonded neodymium magnets are made by mixing neodymium magnetic powder with a binder.

Simply put, they are injection molded, which means they contain a binder. About 80% of the magnet is neodymium powder, and the remaining 20% is binder.

Their benefits include high dimensional accuracy, great design flexibility, and good mechanical strength.

Injection molded neodymium magnets are made by mixing neodymium magnetic powder with thermoplastic. This mix is then injection molded. These magnets are stronger than injection molded ferrite magnets.

Injection molded neodymium magnets can be made into many shapes. They can be small or irregular. You can magnetize them with multiple poles or complex patterns. They are also very accurate and consistent in shape.

These magnets can be molded directly onto motor cores or metal shafts. This saves assembly costs. They are seen as a stronger option than injection molded ferrite magnets. They can work in temperatures up to 180℃.

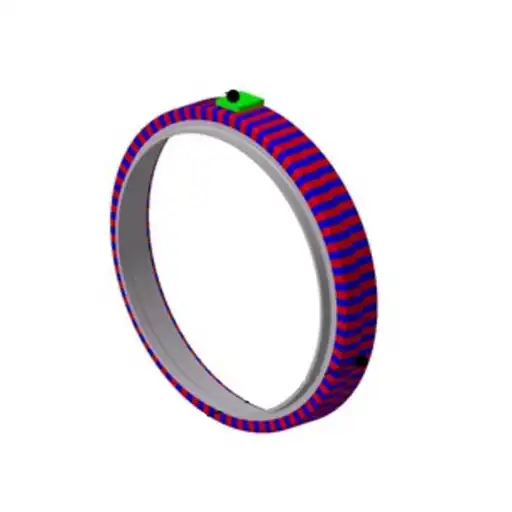

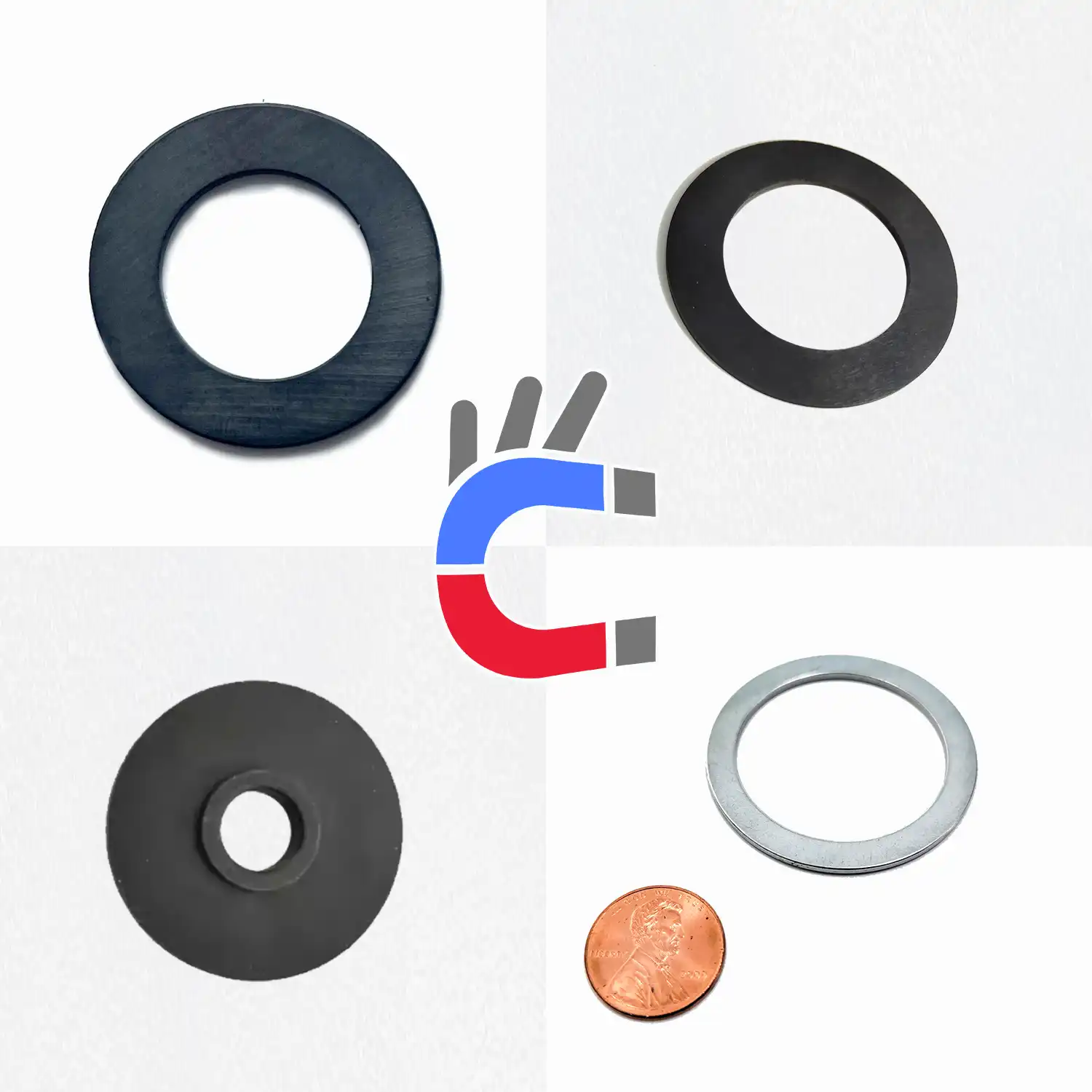

These magnets are injection molded neodymium or ferrite magnets that include a metal carrier. Please see the picture below:

These magnets are injection molded neodymium or ferrite magnets that include a metal carrier. Please see the picture below:

Sintered NdFeB magnets are also called Sintered Neodymium magnets. These are the strongest known permanent magnets. They are made from neodymium (Nd), iron (Fe), boron (B), and other rare earth elements.

These magnets create very strong magnetic fields and stay magnetic at room temperature. They can be made into many shapes. This makes them great for many uses, especially for high-end commercial motors.

Sintering is how they are made. Powdered materials are heated until they merge. This process makes the magnets stronger and more effective.

However, these magnets can corrode easily and are affected by high temperatures. So, they are usually coated (often with a nickel-copper-nickel layer) to protect them. Adding heavy rare earth elements also helps them resist higher temperatures.

- Vulcanized rubber magnet material is made when magnetic powder is added to rubber during a process called vulcanization. This process changes the rubber's structure, making it much stronger, more elastic, and more stable.Vulcanized rubber magnets are often used for magnetic targets on sports robots. They are flexible and don't break easily from shocks.

- Rubber magnets are made from magnetic powder mixed with synthetic rubber. They are formed by extrusion, calendering, or injection molding. You can make them into strips, rolls, sheets, blocks, rings, and many other shapes. Their main advantages are that they are flexible and can be made into various shapes.However, their disadvantage is that they are not very strong (they don't have high remanence) compared to Neodymium magnets. For encoders, regular rubber magnets can't meet high precision needs. They are only good for single-track incremental encoders.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

aroyt778 –

these cores like Magnetics,and bar power just what i want.

philipp-daub –

Good communication and tracking process. Fast response.