Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

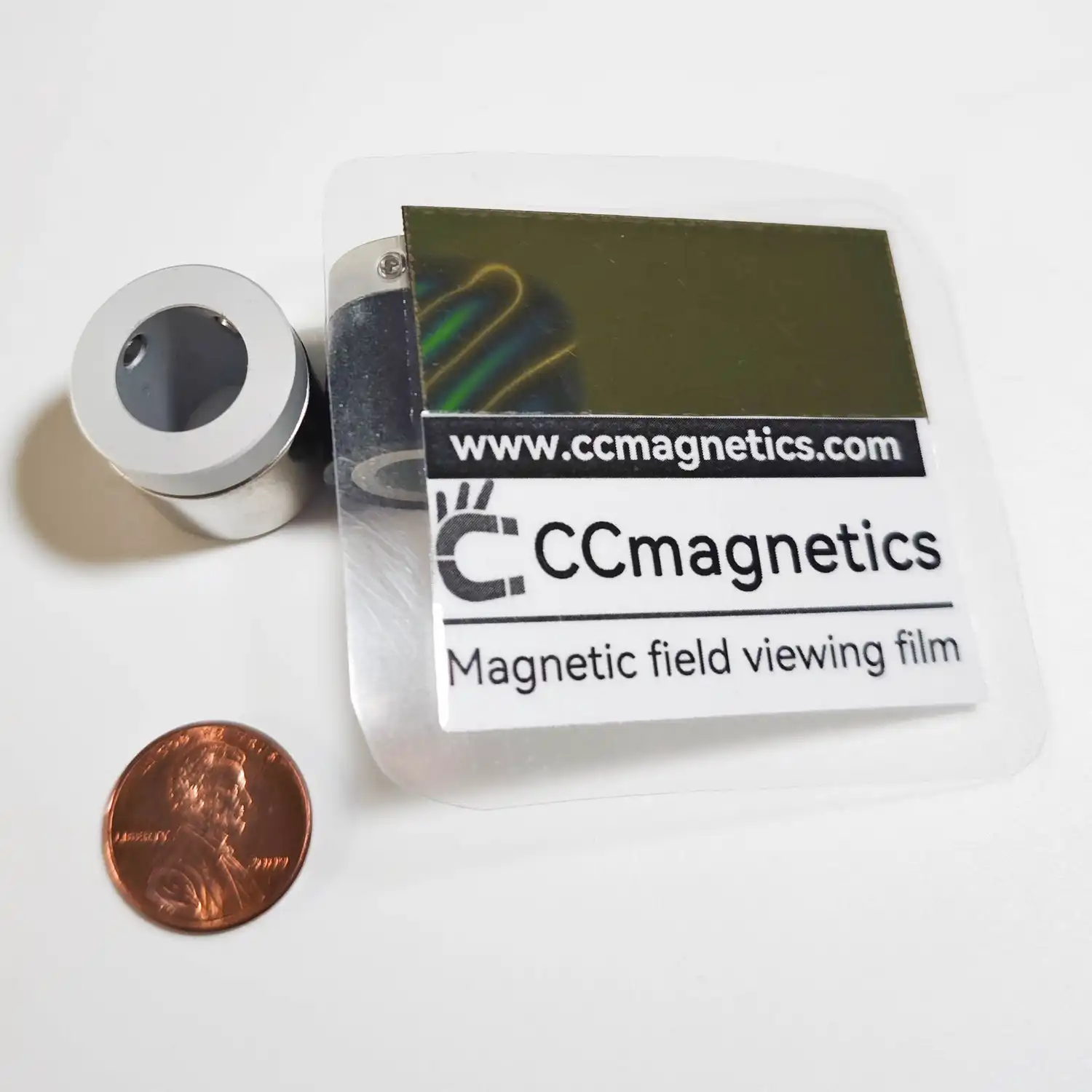

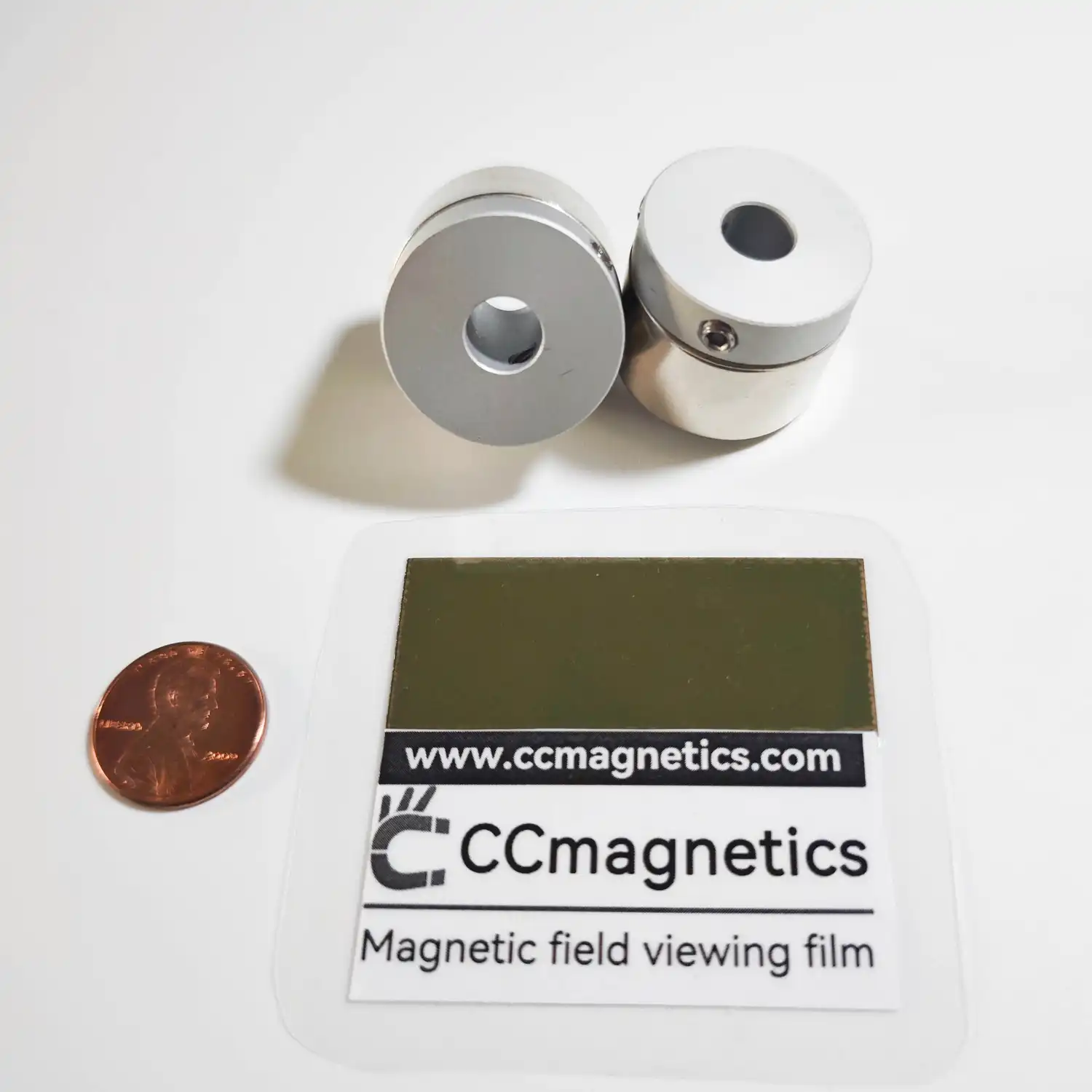

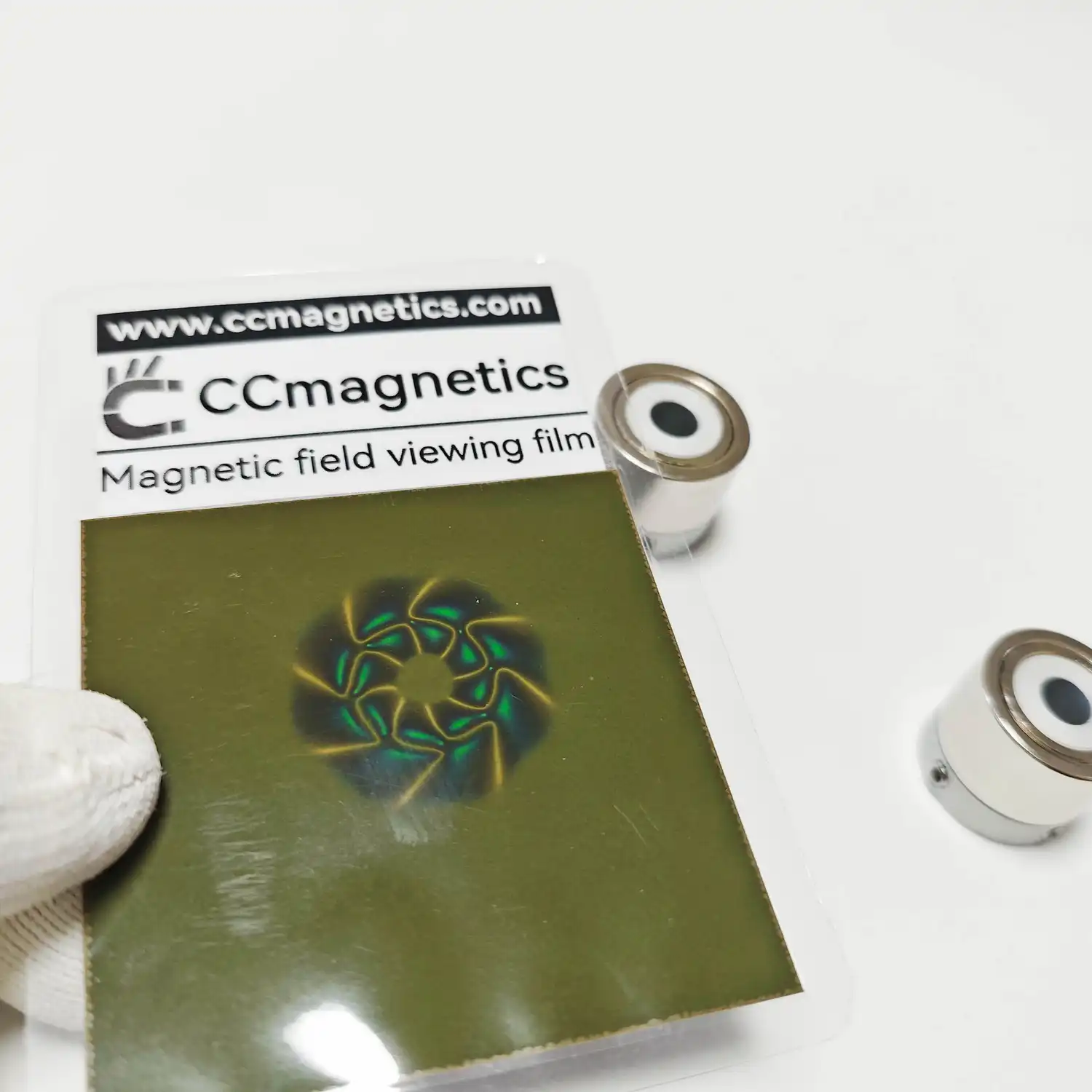

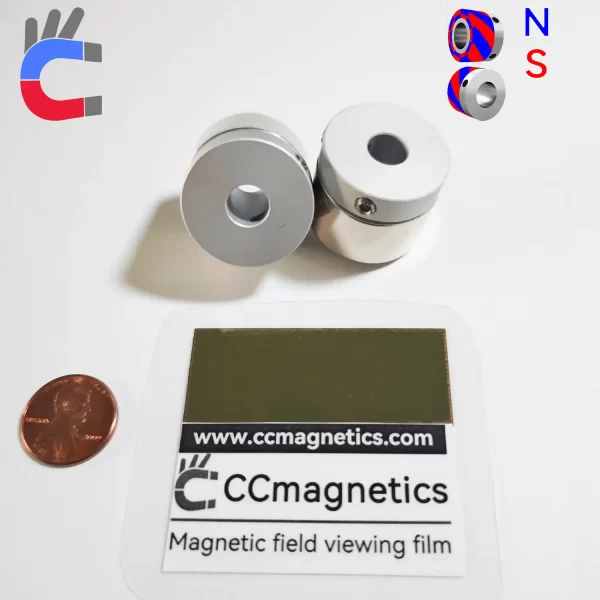

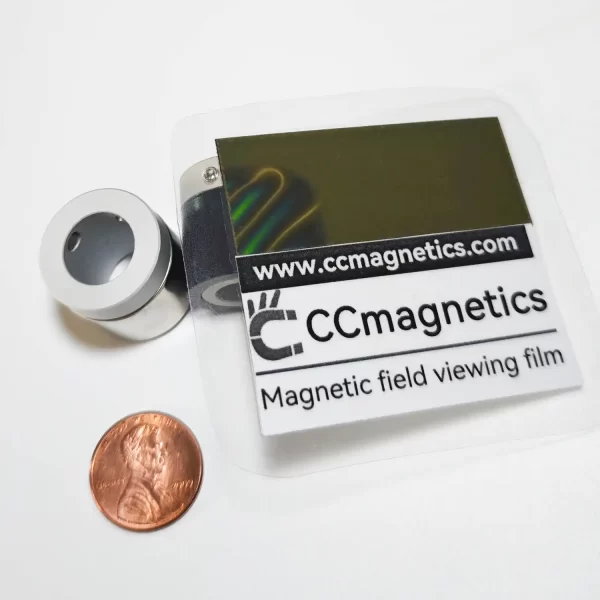

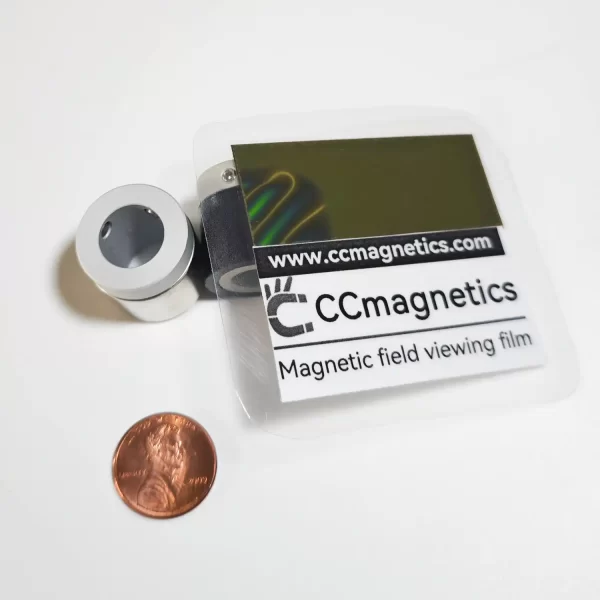

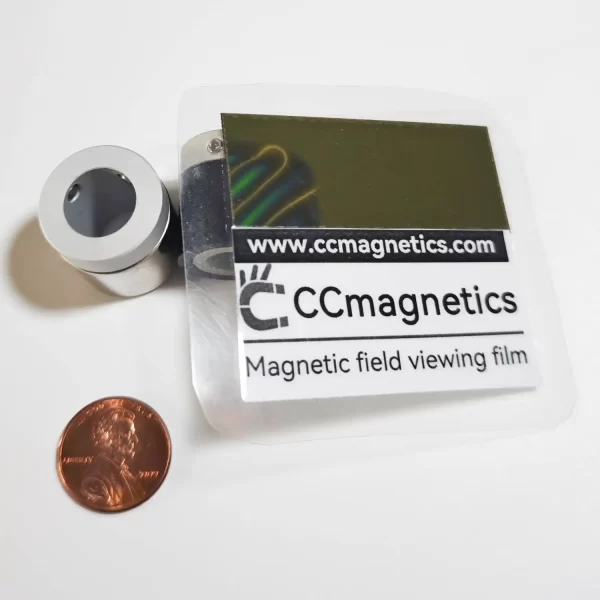

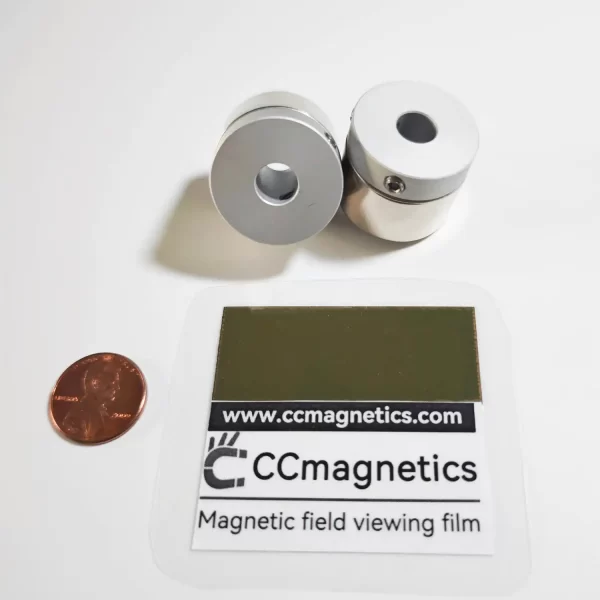

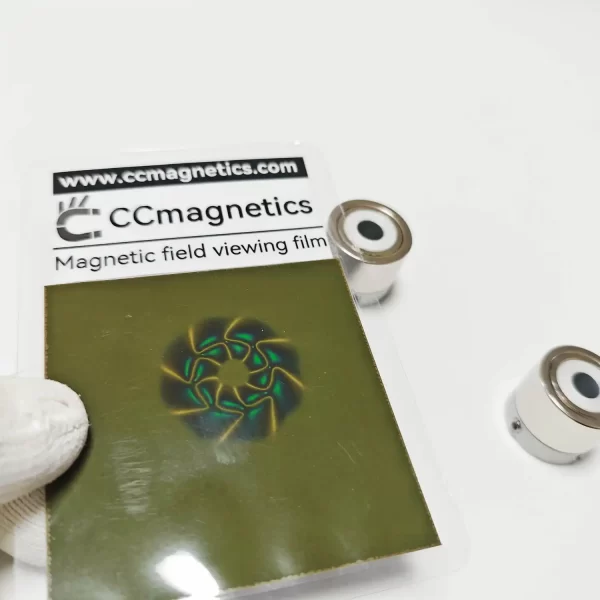

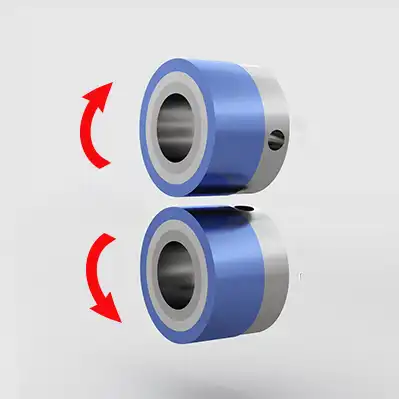

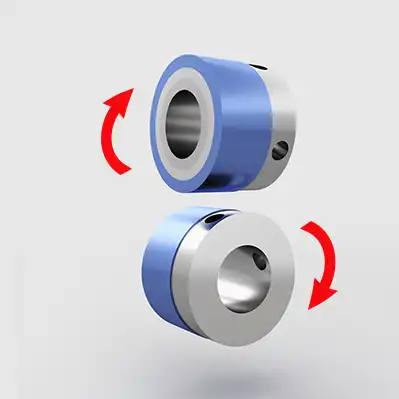

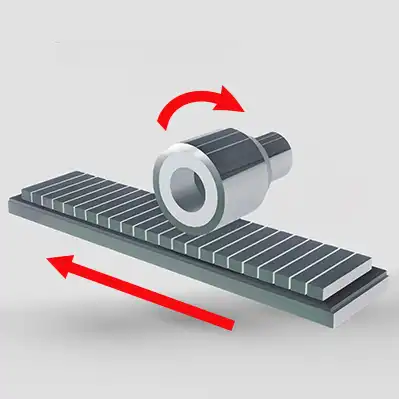

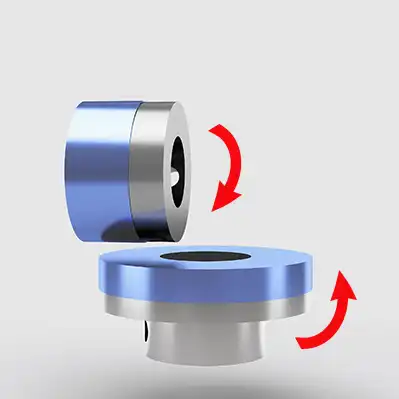

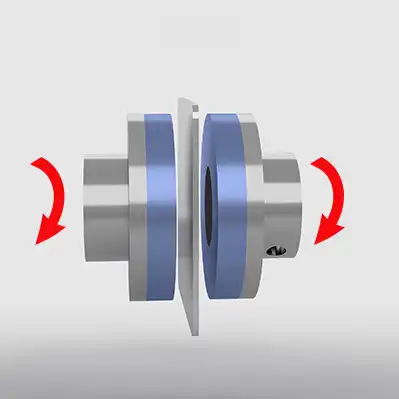

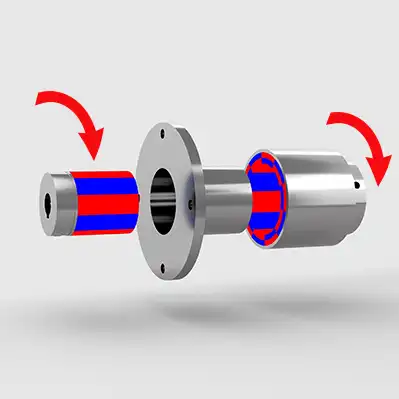

What is Magnetic Gear Drive?

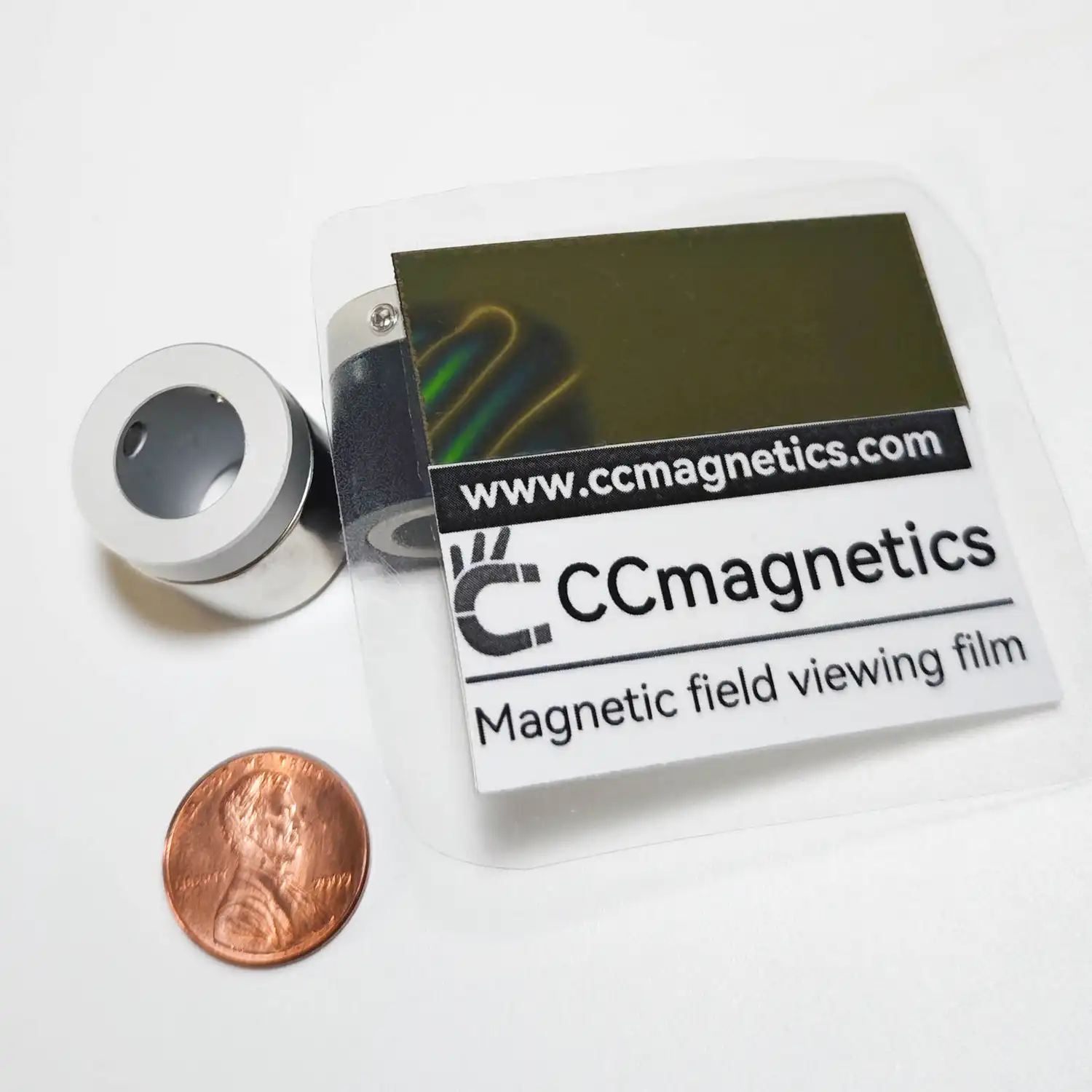

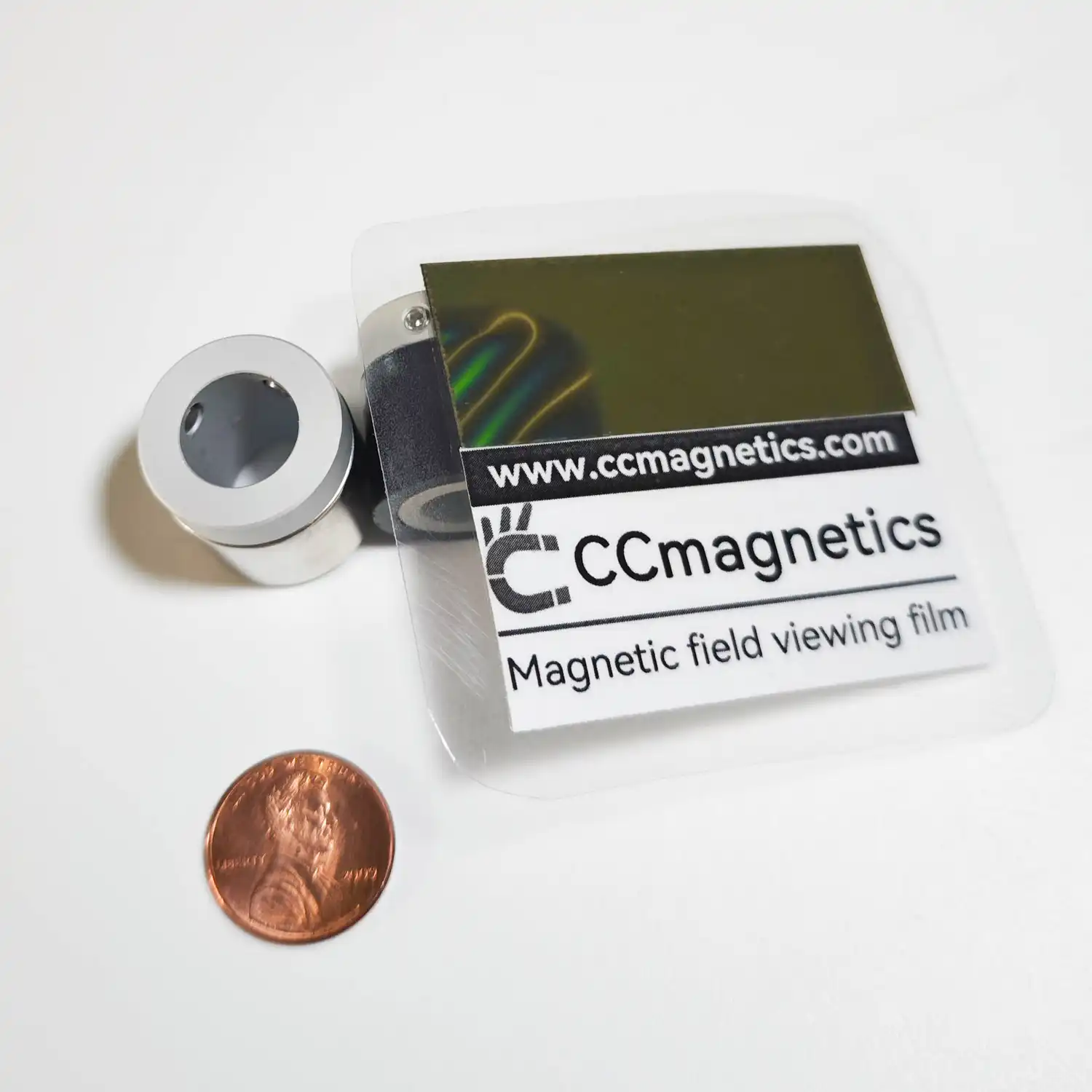

They are non-contact power transmission mechanisms making use of the attraction and repulsion properties of the magnets.

The non-contact magnetic gears using permanent magnets provide smoother motion compared with the power transmission by mechanical gears or belts.

Parameter

| PN | PQ | (I) I.D | SCM | SFM | MC | Tq | (O) O.D | L | W | F | M |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CT13 | 6P | 5~6 | A/S | A | H | 0.012N.m | 13 | 15 | 10 | 2.5 | M3 |

| CT16 | 8P | 5~8 | A/S | A | H | 0.025N.m | 16 | 13 | 8 | 2.5 | M3 |

| CT16 | 12P | 5~8 | A/S | A | H | 0.015N.m | 16 | 13 | 8 | 2.5 | M3 |

| CT18 | 8P | 6~8 | A/S | A | H | 0.05N.m | 18 | 15 | 10 | 2.5 | M3 |

| CT21 | 6P | 6~12 | A/S | C/A | F/H | 0.13N.m | 21 | 21 | 15 | 3 | M4 |

| CT21 | 8P | 6~12 | A/S | C/A | F/H | 0.11N.m | 21 | 21 | 15 | 3 | M4 |

| CT21 | 16P | 6~12 | A/S | C/A | F/H | 0.07N.m | 21 | 21 | 15 | 3 | M4 |

| CT22 | 8P | 8~12 | L/T | A | F/H | 0.09N.m | 22 | 22 | 16 | - | M4 |

| CT22 | 18P | 6~12 | A/S | C/A | F/H | 0.07N.m | 22 | 18 | 12 | 3 | M4 |

| CT25 | 10P | 6~15 | A/S | C/A | F/H | 0.15N.m | 25 | 22 | 15 | 3.5 | M4 |

| CT26 | 8P | 6~15 | A/S | C/A | F/H | 0.2N.m | 26 | 21 | 14 | 3.5 | M4 |

| CT26 | 10P | 6~15 | A/S | C/A | F/H | 0.16N.m | 26 | 21 | 14 | 3.5 | M4 |

| CT26 | 12P | 6~15 | A/S | C/A | F/H | 0.14N.m | 26 | 21 | 14 | 3.5 | M4 |

| CT26 | 20P | 6~15 | A/S | C/A | F/H | 0.05N.m | 26 | 21 | 14 | 3.5 | M4 |

| CT27 | 8P | 8~12 | L/T | A | F/H | 0.14N.m | 27 | 22 | 15 | - | M4 |

| CT27 | 10P | 8~12 | L/T | A | F/H | 0.11N.m | 27 | 22 | 15 | - | M4 |

| CT28 | 8P | 8~15 | A/S | C/A | F/H | 0.22N.m | 28 | 25 | 17 | 4 | M4 |

| CT29 | 8P | 8~15 | L/T | C/A | F/H | 0.25N.m | 29 | 25 | 17 | 4 | M4 |

| CT30 | 8P | 10~15 | L/T | C/A | F/H | 0.31N.m | 30 | 25 | 18 | 3.5 | M4 |

| CT30 | 10P | 10~15 | L/T | C/A | F/H | 0.28N.m | 30 | 25 | 18 | 3.5 | M4 |

| CT31 | 8P | 10~20 | L/T | A | F/H | 0.25N.m | 31 | 25 | 18 | - | M4 |

| CT31 | 10P | 10~20 | L/T | A | F/H | 0.23N.m | 31 | 25 | 18 | - | M4 |

| CT32 | 08P | 8~20 | A/S | C/A | F/H | 0.4N.m | 32 | 30 | 20 | 5 | M4 |

| CT32 | 10P | 8~20 | A/S | C/A | F/H | 0.32N.m | 32 | 30 | 20 | 5 | M4 |

| CT32 | 12P | 8~20 | A/S | C/A | F/H | 0.28N.m | 32 | 30 | 20 | 5 | M4 |

| CT32 | 20P | 8~20 | A/S | C/A | F/H | 0.09N.m | 32 | 30 | 20 | 5 | M4 |

| CT35 | 08P | 8~20 | A/S | C/A | F/H | 0.55N.m | 35 | 32 | 21.5 | 5.25 | M5 |

| CT35 | 10P | 8~20 | A/S | C/A | F/H | 0.45N.m | 35 | 32 | 21.5 | 5.25 | M5 |

| CT35 | 12P | 8~20 | A/S | C/A | F/H | 0.36N.m | 35 | 32 | 21.5 | 5.25 | M5 |

| CT35 | 18P | 8~20 | A/S | C/A | F/H | 0.36N.m | 35 | 32 | 21.5 | 5.25 | M5 |

| CT36 | 08P | 10~20 | L/T | A | F/H | 0.4N.m | 36 | 32 | 22 | - | M5 |

| CT36 | 10P | 10~20 | L/T | A | F/H | 0.35N.m | 36 | 32 | 22 | - | M5 |

| CT36 | 12P | 10~20 | L/T | A | F/H | 0.3N.m | 36 | 32 | 22 | - | M5 |

| CT39 | 08P | 15~20 | A/S | C/A | F/H | 0.8N.m | 39 | 35.8 | 26.6 | 4.6 | M5 |

| CT39 | 12P | 15~20 | A/S | C/A | F/H | 0.58N.m | 39 | 35.8 | 26.6 | 4.6 | M5 |

| CT39 | 16P | 15~20 | A/S | C/A | F/H | 0.4N.m | 39 | 35.8 | 26.6 | 4.6 | M5 |

| CT40 | 12P | 10-20 | L/T | A | F/H | 0.58N.m | 40 | 36.5 | 26 | - | M5 |

| CT40 | 16P | 15~25 | A/S | C/A | F/H | 0.42N.m | 40 | 34 | 24 | 5 | M5 |

| CT42 | 12P | 15~25 | A/S | C/A | F/H | 0.74N.m | 42 | 30 | 21 | 4.5 | M5 |

| CT42 | 18P | 15~25 | A/S | C/A | F/H | 0.42N.m | 42 | 30 | 21 | 4.5 | M5 |

| CT45 | 10P | 15~30 | A/S | C/A | F/H | 1.2N.m | 45 | 35 | 25 | 4.5 | M4 |

| CT45 | 12P | 15~30 | A/S | C/A | F/H | 0.95N.m | 45 | 35 | 25 | 4.5 | M4 |

| CT46 | 10P | 15-25 | L/T | A | F/H | 0.83N.m | 46 | 27 | 26 | - | M5 |

| CT52 | 10P | 20~35 | A/S | C/A | F/H | 1.45N.m | 52 | 37 | 25 | 5 | M5 |

| CT53 | 10P | 20~30 | L/T | A | F/H | 0.95N.m | 53 | 37 | 26 | - | M5 |

| CT65 | 18P | 20~40 | A/S | C/A | F/H | 1.95N.m | 65 | 50 | 35 | 7.5 | M6 |

| No. | Item | Description | Notes |

|---|---|---|---|

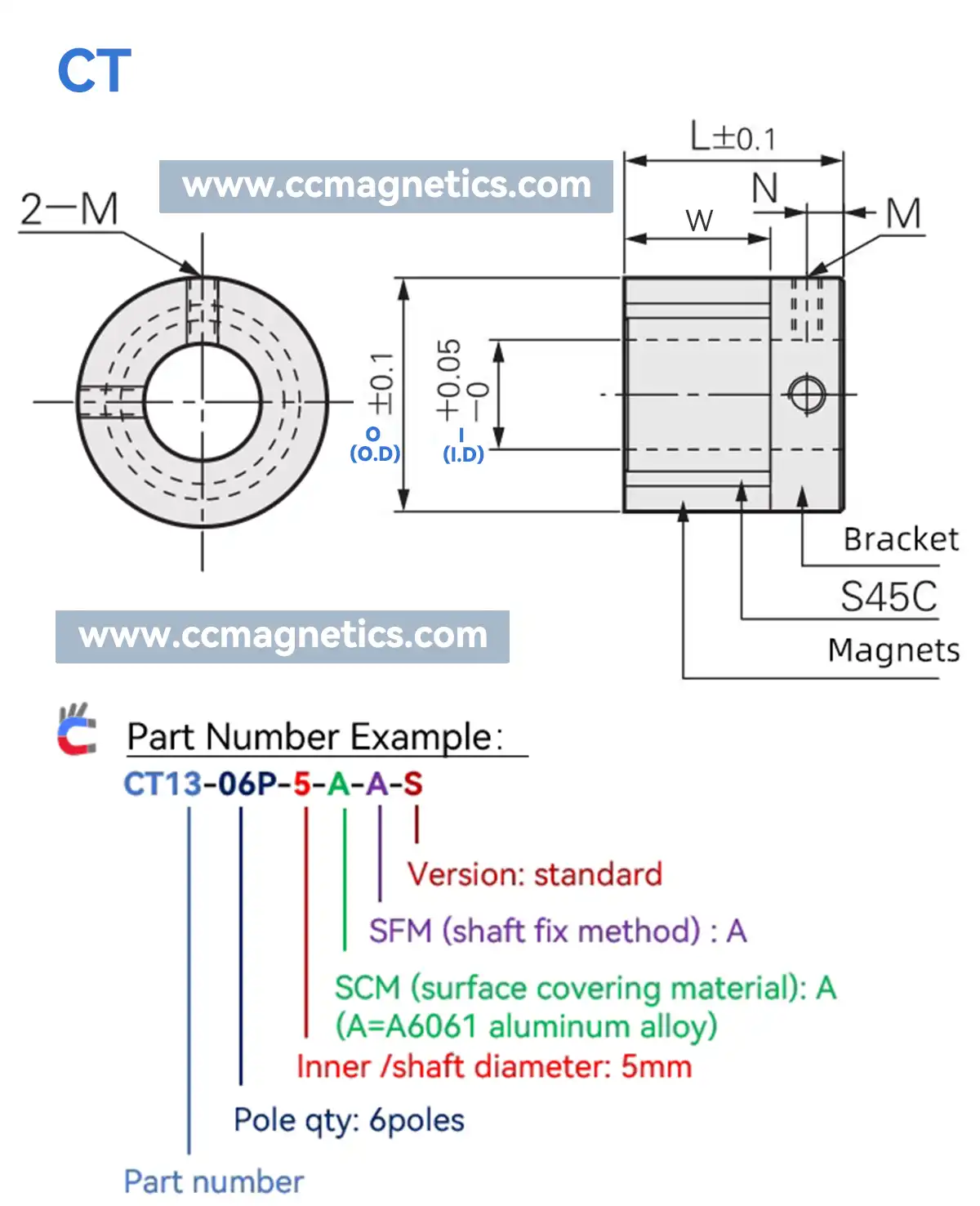

| 1 | PN | Part Number | The number after PN is the outer diameter of the magnetic coupling in millimeters. |

| 2 | PQ | Pole Quantity | Number of magnets on one magnetic coupling. |

| 3 | I | Inner Diameter | Unit of length is millimeters. |

| 4 | SCM | Surface Covering Material | A=A6061 (aluminum alloy), S=SUS304 (stainless steel), L=SUS316L (stainless steel), T=TC4 (Titanium Alloy). |

| 5 | SFM | Shaft Fixing Method | Type A: Setscrew Type B: Setscrew and keyway Type C: Clamping hub slot and keyway. Refer to the drawing for the shaft fixing method. |

| 6 | MC | Metal Casing Coverage | F= Fully H= Half |

| 7 | Tq | Torque | The torque value shown is for a 1mm gap. |

| 8 | O | Outer diameter. | Unit of length is millimeters. |

| 9 | L,W,F,M | Unit of length on the drawing. | Unit of length is millimeters. |

Advantages of magnetic gears products

- Very low noise and vibration

- No wear No dust

- No heat generation

- Oil-free

- Power transmission through wall

- Torque limiter function

- Easy attaching and detaching

- Large tolerance for declination and eccentricity

Support a wide variety of magnetic gears

- In order to meet the customer s specifications such as anti-corrosion and heat resistance, We offer a variety of materials and surface treatments suited for various atmospheres.

- We can customize magnets with high magnetic force and anti-rust effect are selected depending on the applications.

- We are willing to accept the unitization request and co-develop with customers.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語

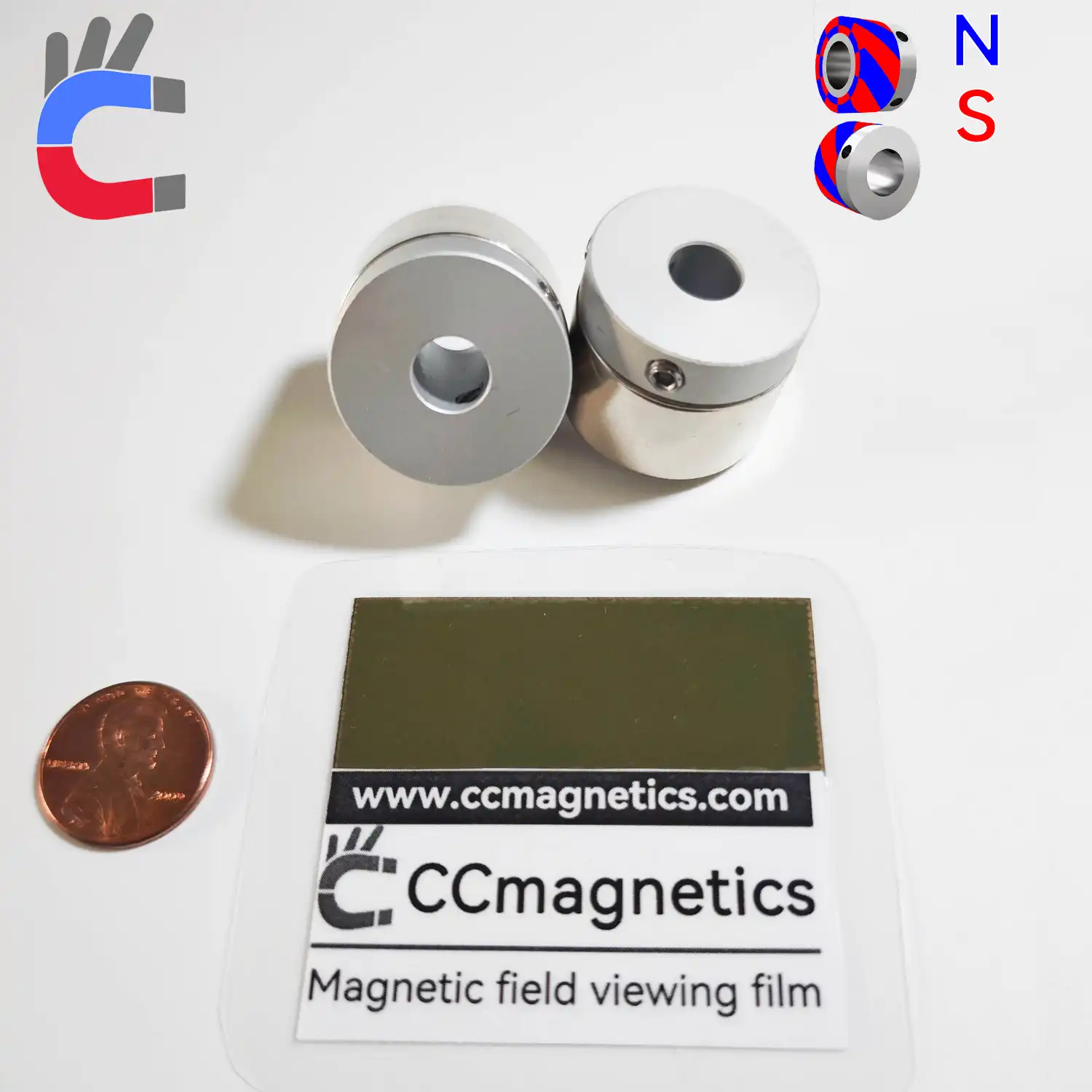

lannguyen845 –

Very good quality product, as always. Well packaged and delivered in a timely fashion

kgross0302 –

Very easy, great magnet assembly, super quick. Highly Recommend.