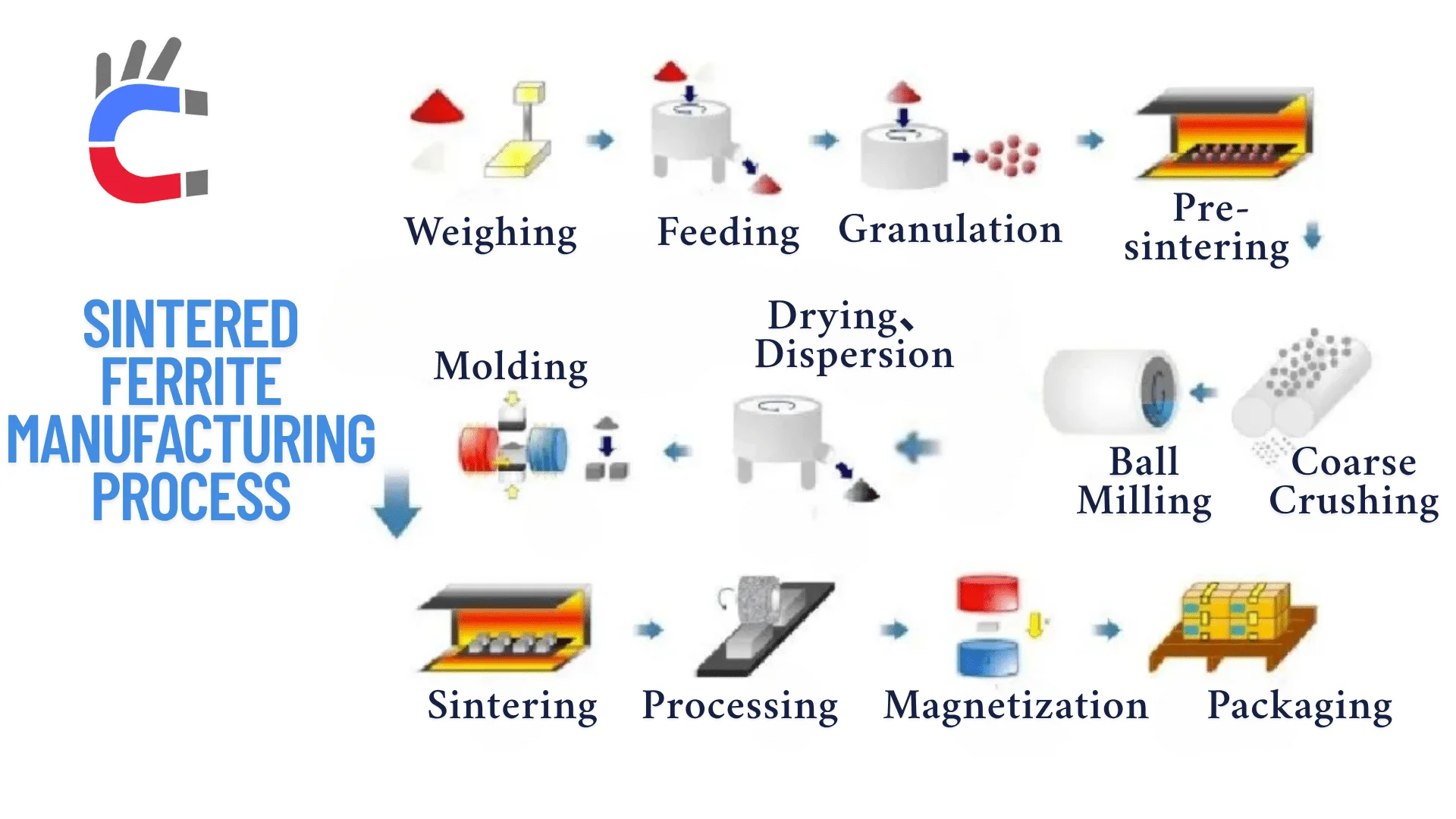

The production of sintered permanent ferrite is a sophisticated and complex ceramic manufacturing process aimed at transforming basic oxide raw materials into hard magnets with stable and excellent magnetic properties. The entire process can be divided into the following six key steps:

1. Raw Material Preparation and Formulation

- Raw Material Selection: The main raw materials are high-purity ferric oxide (Fe2O3) and strontium carbonate (SrCO3) or barium carbonate (BaCO3). The purity and particle size of these raw materials are crucial for the final product's magnetic performance. The purity of Fe2O3 is typically required to be above 99%.

- Proportioning and Mixing: Raw materials are weighed according to precise chemical ratios based on the target magnetic properties. They are then thoroughly mixed using high-speed blenders or ball mills to ensure uniform composition. Some large enterprises use computer-controlled automatic batching systems to enhance accuracy and consistency.

2. Pre-sintering

- Purpose and Principle: This is a critical solid-state reaction process. The mixed powder is calcined at high temperatures, typically between 1100°C and 1300°C. This promotes a chemical reaction between the Fe2O3 and SrCO3 (or BaCO3), forming the hexagonal ferrite crystalline phase, such as SrFe12O19.

- Process Control: Strict control of pre-sintering temperature, time, and atmosphere is essential. Temperatures that are too high can cause excessive grain growth, negatively impacting magnetic performance, while temperatures that are too low result in an incomplete reaction.

3. Crushing and Milling

- Coarse Crushing: The blocky material from pre-sintering is crushed into smaller granules (several to ten millimeters) using equipment like jaw crushers.

- Fine Milling: This is a key step for achieving high magnetic performance. The coarse granules are ground to a micron size (typically 1-2 micrometers) using a ball mill or vibratory mill, which increases the specific surface area. The milling time, ball-to-material ratio, and rotational speed must be precisely controlled to ensure a uniform particle size distribution.

4. Molding

Molding shapes the powder into a green body with a predetermined form and size. The method depends on the product requirements:

-

Dry Pressing:

- Principle: Dry magnetic powder is directly pressed into a mold without an external magnetic field.

- Characteristics: Simple process, high production efficiency, and low cost. It is suitable for isotropic magnets or products with less stringent magnetic performance requirements.

-

Dry Magnetic Field Pressing:

- Principle: An external magnetic field is applied while the powder is being pressed. The magnetic particles align along the direction of the field, creating an anisotropic green body.

- Characteristics: This method produces products with higher magnetic performance and is the most widely used for dry-pressed permanent ferrites.

-

Wet Pressing:

- Principle: A slurry of magnetic powder and water is pressed in a strong magnetic field.

- Characteristics: This method yields higher density and magnetic performance but is more complex and costly, typically reserved for high-performance products.

5. Sintering

- Purpose and Function: Sintering is the crucial step where the green body is densified and acquires its final magnetic properties.

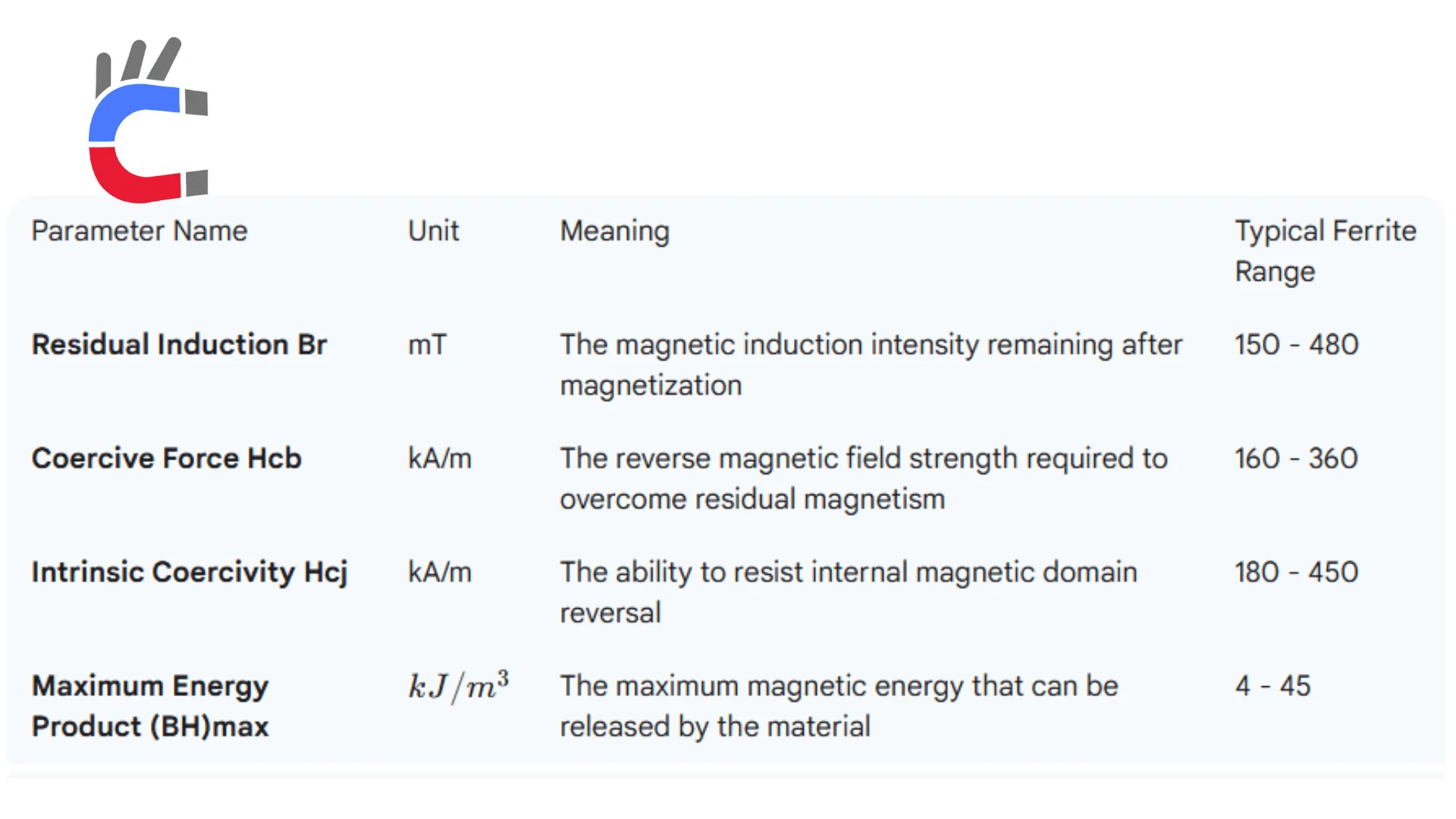

- Process Optimization: In a high-temperature furnace (1200°C to 1400°C), atoms diffuse between particles, and grain boundaries fuse, significantly increasing the material's density and forming a hard, dense ceramic body. By optimizing the sintering profile, such as multi-stage heating and atmosphere control, manufacturers can prevent excessive grain growth and achieve optimal magnetic properties like coercivity, remanence, and maximum energy product.

6. Post-Processing

- Mechanical Processing: The sintered magnets are hard but brittle. They are cut, ground, and drilled using diamond tools to meet the required dimensions and precision (e.g., up to ±0.01mm for precision motors).

- Surface Treatment: Depending on the application environment, the magnets may undergo surface treatments like coating or plating to improve corrosion resistance or appearance.

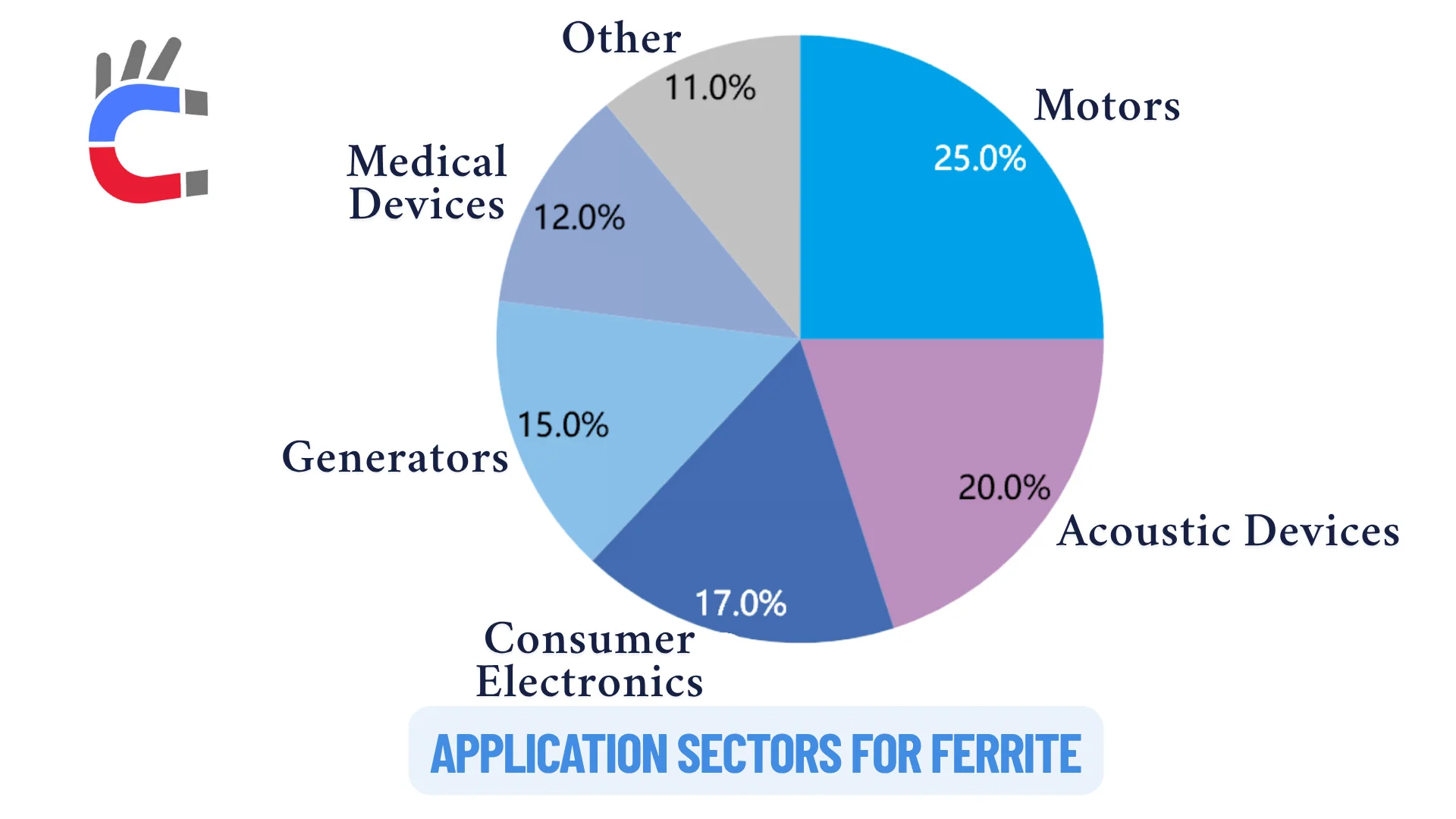

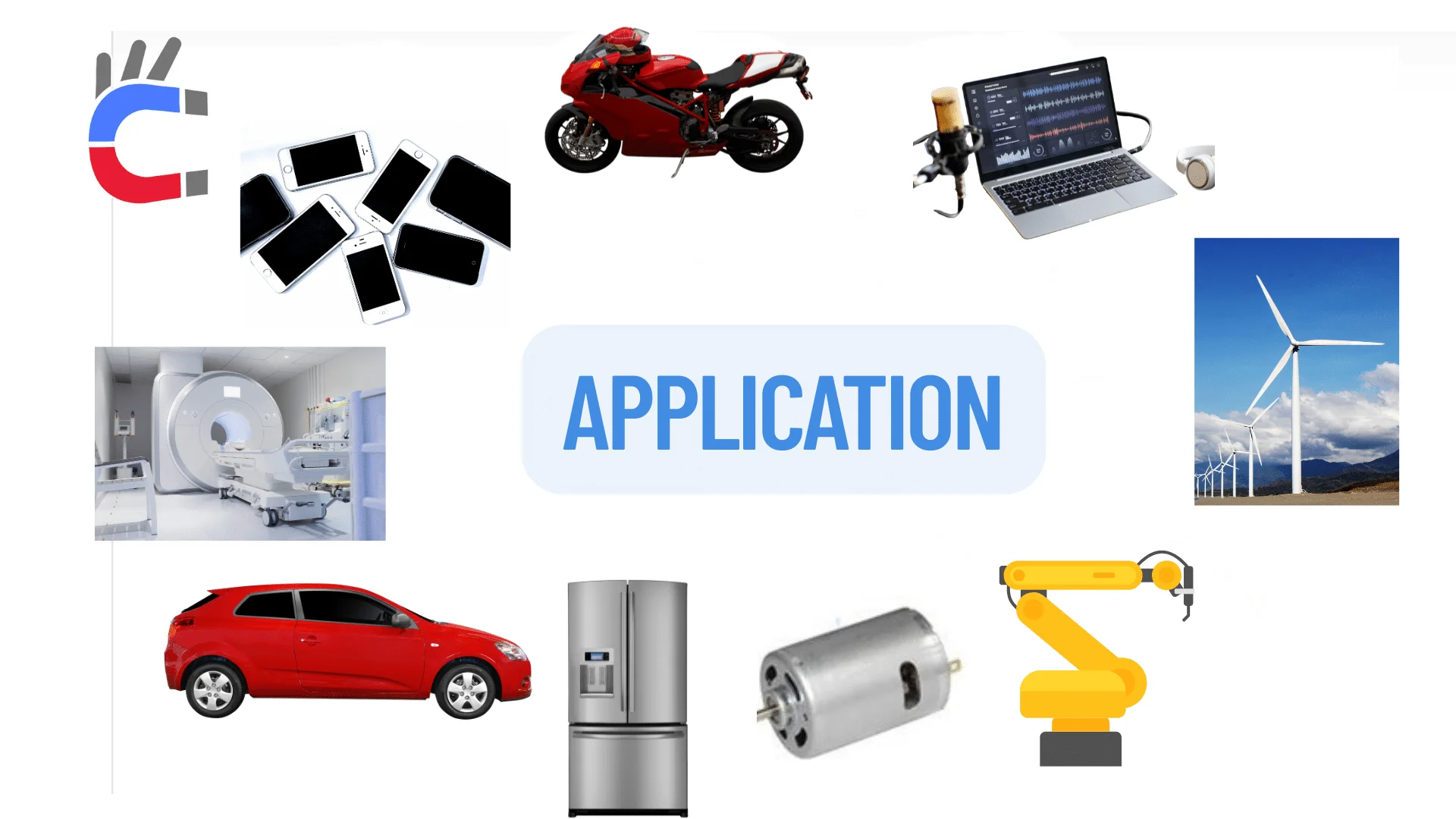

Application Fields of Sintered Permanent Ferrite

Sintered permanent ferrite is indispensable in many key industries due to its cost-effectiveness, stable magnetic properties, and corrosion resistance.

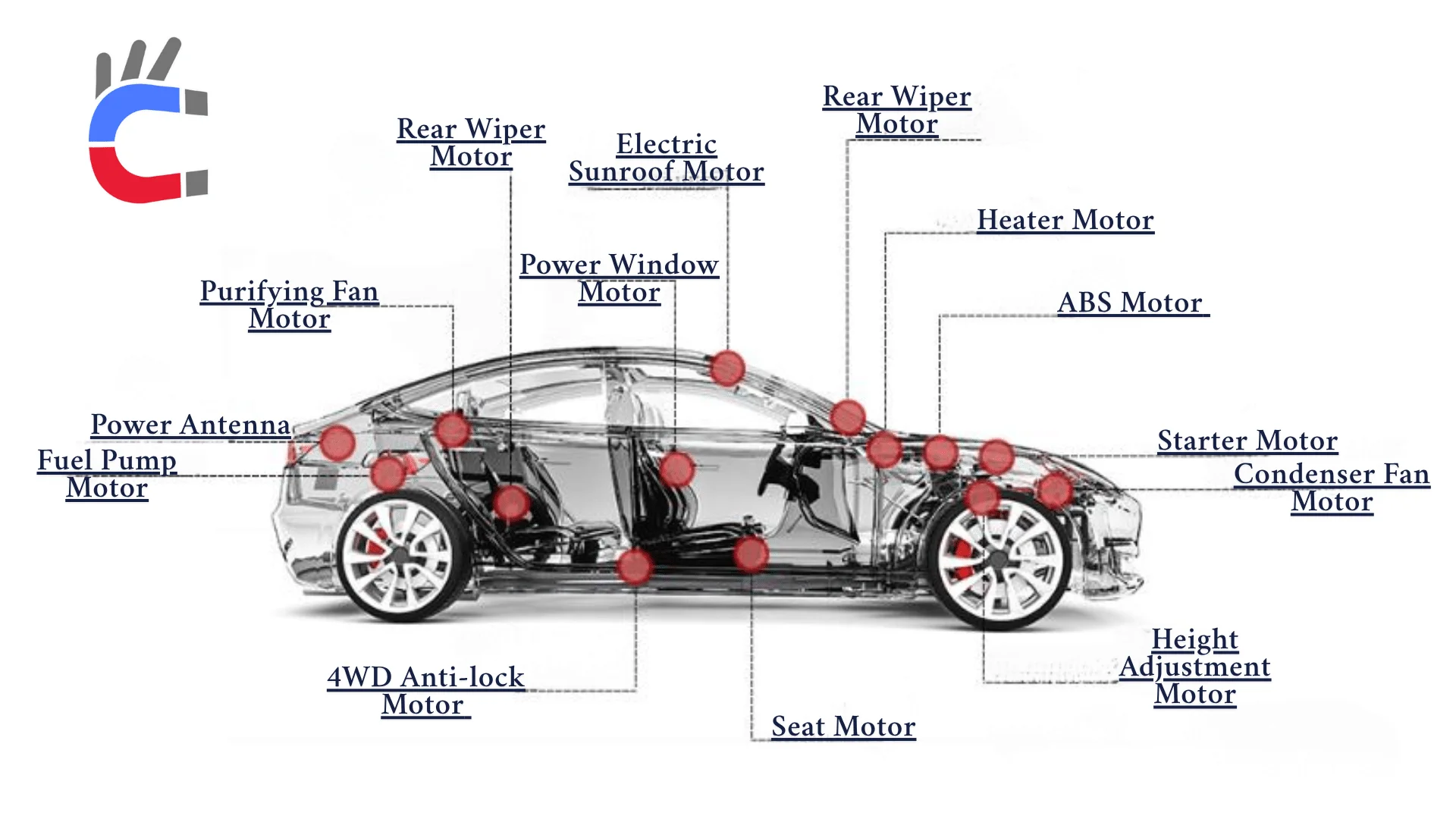

1. Automotive Industry

-

Motor Applications: This is the largest application area. With the trend towards automotive electrification and lightweight design, the number of ferrite magnets per vehicle is continuously increasing.

- New Energy Vehicles: Used in drive motors for some mid-to-low-end models, steering assist motors, and windshield wiper motors.

- Traditional Vehicles: Found in starter motors, power window motors, air conditioner blower motors, power seat adjusters, anti-lock braking system (ABS) motors, and cooling fan motors.

-

Sensors: Used in wheel speed and position sensors, where their stable magnetic fields convert physical quantities into electrical signals.

2. Home Appliance Sector

- Motor Applications: Widely used in motors for air conditioners, refrigerators, washing machines, and air purifiers. Compared to traditional induction motors, ferrite motors can save 10-20% of electricity, reduce noise, and improve energy efficiency.

- Small Appliances: Motors for vacuum cleaners and electric shavers use ferrite magnets to provide strong power, reduce size, and make products more compact.

3. Consumer Electronics and Audio Equipment

- Speakers: Ferrite magnets serve as the magnetic source for speakers, providing a stable magnetic field for the voice coil to produce sound. They are widely used in headphones, speakers, televisions, and radios.

- Hard Disk Drives: Used in the head drive system to help the read/write head quickly and accurately seek and access data.

4. Industrial and Medical Fields

- Power Tools: Motors in power tools like drills and saws commonly use ferrite magnets for their powerful and efficient performance.

- Instrumentation: Used in meters like water and gas meters.

- Medical Equipment: Found in auxiliary magnetic components for Magnetic Resonance Imaging (MRI) machines and in magnetic therapy devices.