Maintaining a ship's hull is a challenging task, often involving a high-altitude, vertical, and curved surface environment that poses safety risks and leads to low efficiency with traditional manual labor.

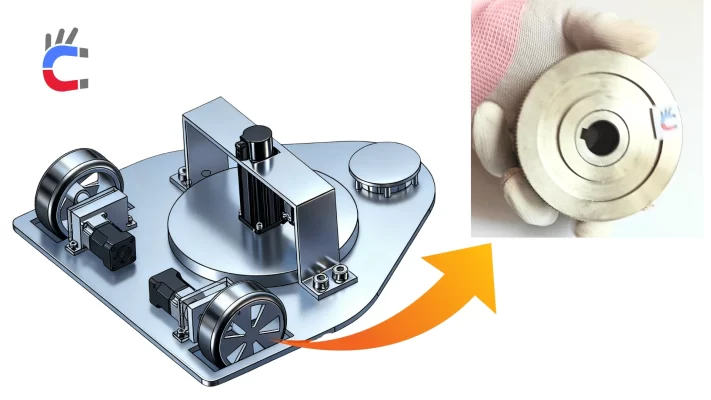

The three-wheeled magnetic crawler, with its unique design and core technology, offers an ideal solution to these issues. Compared to common four-wheeled magnetic crawlers, the three-wheeled version is better suited for ship maintenance. Its advantages are evident in four key areas.

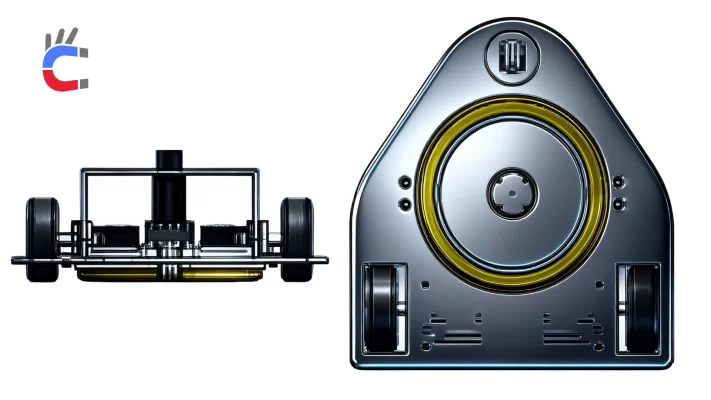

1. Unique Three-Wheel Structure for Complex Surfaces

The three-wheeled magnetic crawler features an asymmetrical design with one small front wheel and two large rear wheels. This structure precisely addresses the demands of working on a ship's surface, creating a distinct advantage over four-wheeled crawlers.

- Front Wheel Flexibility: The smaller front wheel makes steering easier, allowing the crawler to navigate curved surfaces like the bow and stern with agility. This design helps it avoid the "steering lag" common in traditional multi-wheeled devices. In contrast, four-wheeled crawlers, which have uniform wheel sizes, are prone to steering delays or even skidding on small-radius curves.

- Rear Wheel Stability: The larger rear wheels provide a wider contact area and, combined with an anti-slip design, offer stable support on vertical or inclined surfaces. This ensures the crawler remains steady even when it encounters slight vibrations, guaranteeing the precision of cleaning and rust removal. While four-wheeled crawlers can handle flat surfaces, they have poor balance on inclines and may cause the working module to shift.

- Strong Overall Adaptability: The three-wheeled crawler can adapt to both flat deck sides and highly curved cabin surfaces through coordinated wheel movement, eliminating the need for frequent equipment changes or mode adjustments. Four-wheeled crawlers often have dead zones in complex areas because their large wheels cannot adequately "wrap around" small-curvature surfaces, which requires manual assistance to adjust.

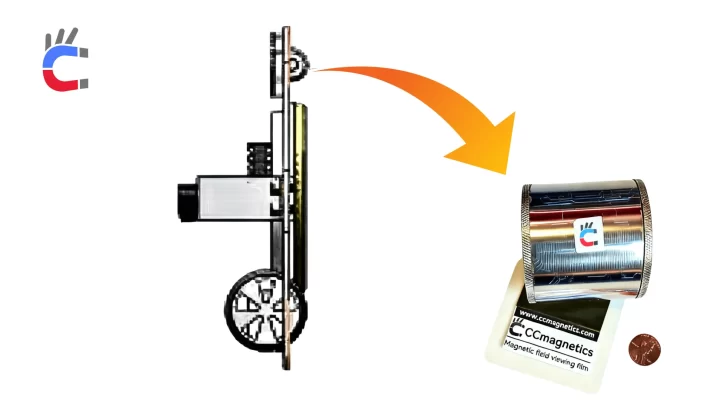

Magnetic Transmission

2. Powerful Magnetic Adhesion Technology for Vertical Operations

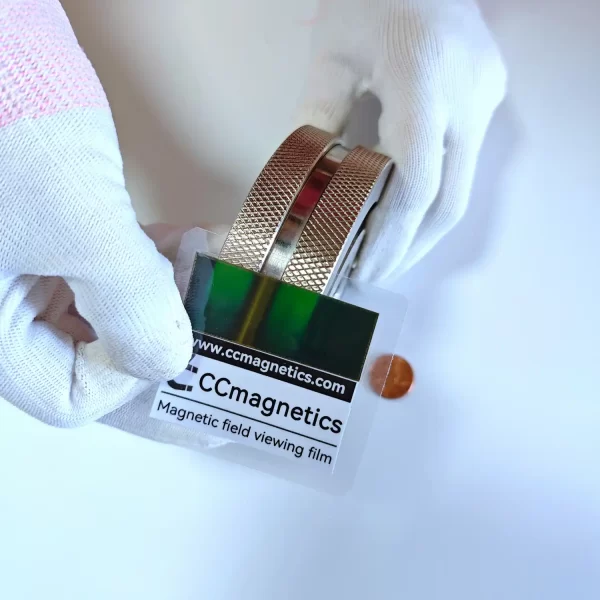

The powerful magnets built into each

magnetic wheel are a core competitive advantage of the three-wheeled magnetic crawler. Its adhesion design is highly compatible with the complex environment of a ship's surface.

- High Adhesion for Safety: The magnetic wheel adheres firmly to the ship's steel surface, preventing the vehicle from falling even when working on a 90° vertical wall or upside down. This completely eliminates the safety risks of manual suspended work.

- Adaptability to Complex Environments: The magnetic wheel's adhesion is unaffected by wet or slightly rusty hull surfaces, ensuring continuous operation. In comparison, four-wheeled magnetic crawlers, with their larger contact area, may lose local adhesion if the surface has raised rust spots, which can lead to adhesion fluctuations and require frequent checks.

3. Multi-Tasking Integration for Enhanced Maintenance Efficiency

The three-wheeled magnetic crawler is a multi-functional platform that can integrate various operational modules.

- Efficient Cleaning: Equipped with high-pressure spray or brush modules, it can quickly remove marine biofouling from the hull, with a cleaning efficiency 3 to 5 times greater than manual labor and fewer blind spots.

- Precise Rust Removal: It can be fitted with small grinding or sandblasting components to handle localized rust precisely, avoiding the coating damage that can result from traditional large-area rust removal.

- Simultaneous Inspection: The crawler can integrate high-definition cameras or sensors to collect data on the hull surface during cleaning and rust removal, enabling timely detection of cracks or dents. This offers an integrated "maintenance + detection" solution.

4. Reduced Reliance on Manual Labor for Cost and Safety Optimization

The three-wheeled magnetic crawler’s automated design effectively solves the high costs and safety risks associated with traditional manual maintenance.

- Reduced Labor Input: One crawler can replace two to three workers and can be operated remotely.

- Lowered Safety Risks: Since personnel do not need to work on high or vertical surfaces, the risks of high-altitude accidents are fundamentally avoided. The smaller size and lighter weight of the three-wheeled crawler also make retrieval and repair easier if a malfunction occurs.

- Controlled Maintenance Costs: The three-wheeled crawler does not require frequent replacement of consumables and has a long battery life, making its long-term usage cost significantly lower than manual labor.

Conclusion

From its structural adaptability and magnetic adhesion safety to its multi-task efficiency and cost control, the three-wheeled magnetic crawler is a better fit for the core needs of ship maintenance than the four-wheeled magnetic crawler. It not only solves the challenges of traditional work but also overcomes the limitations of four-wheeled crawlers in adapting to complex curves.

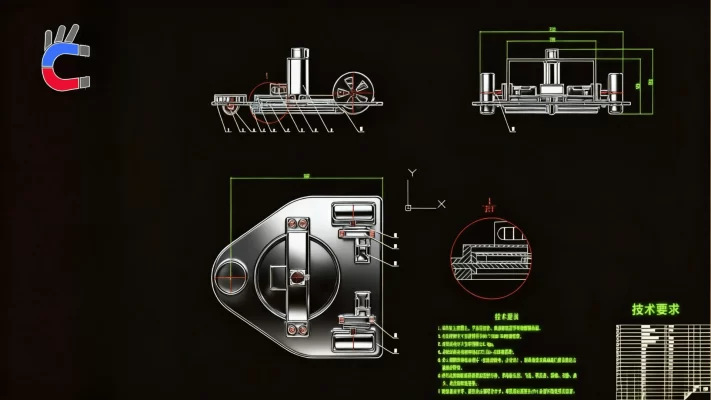

If you purchase our magnetic wheels for magnetic crawlers, we will provide the CAD and Solid Works 3D drawings for a three-wheel magnetic crawler for free.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語