Ruedas Magnéticas,Ruedas Magnéticas para Robots,Ruedas Magnéticas para Coche,Ruedas Magnéticas para Robots,Ruedas Magnéticas para Coche,Ruedas Magnéticas para Robots,Ruedas Magnéticas para Coche

Original factory, accept visitors

Free design, technical support

Quality assurance, one year warranty

¡Desata el poder trepador de tus robots con las innovadoras ruedas magnéticas de CCmagnetics!

Las ruedas magnéticas para robots, fabricadas principalmente con potentes imanes de neodimio, ofrecen una adherencia superior a las superficies ferrosas. Esto permite a los robots atravesar paredes verticales sin esfuerzo, por lo que son ideales para aplicaciones como:

- Robots trepamuros

- Inspección de barcos

- Mantenimiento de aerogeneradores

- Limpieza exterior de edificios

Parámetros:

Consejos

Título de la tabla Explicación: PN significa Número de Pieza.

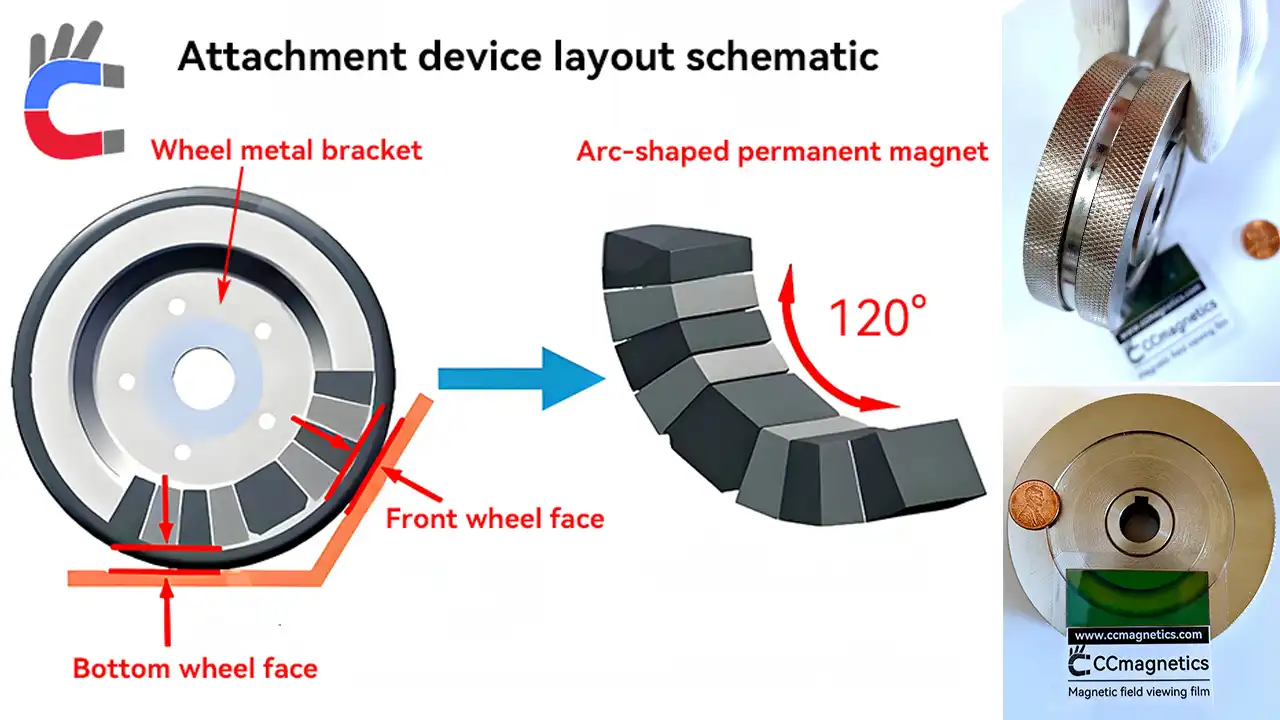

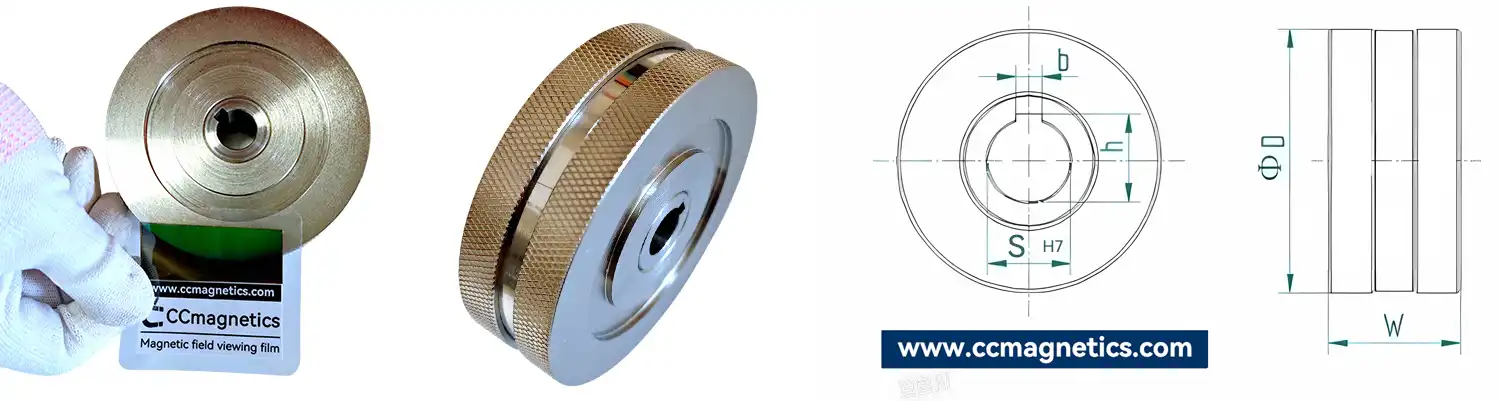

Para conocer el significado de D, W, S, B y H, consulte el dibujo. El valor de S es un rango sugerido, y los valores finales de B, H y S se basarán en sus requisitos específicos.

- Peso propio es el peso de una sola rueda.

- Load Cap es la capacidad de carga máxima de una sola rueda.

| PN | D (mm) | W (mm) | S (mm) | B & H (mm) | Self-Wt (kgs) | Pull Force (kgf) | Pull Force (N) |

|---|---|---|---|---|---|---|---|

| MW40-25 | 40 | 25 | 8 | Upon Request | 0.28 | 8 | 78 |

| MW50-25 | 50 | 25 | 8~12 | Upon Request | 0.4 | 10 | 98 |

| MW50-30 | 50 | 30 | 8~12 | Upon Request | 0.48 | 14 | 137 |

| MW50-40 | 50 | 40 | 8~12 | Upon Request | 0.64 | 22 | 216 |

| MW50-50 | 50 | 50 | 8~12 | Upon Request | 0.8 | 30 | 294 |

| MW60-25 | 60 | 25 | 8~12 | Upon Request | 0.59 | 15 | 147 |

| MW60-30 | 60 | 30 | 8~12 | Upon Request | 0.71 | 19 | 186 |

| MW60-40 | 60 | 40 | 8~12 | Upon Request | 0.95 | 27 | 265 |

| MW60-50 | 60 | 50 | 8~12 | Upon Request | 1.18 | 35 | 343 |

| MW65-25 | 65 | 25 | 12~16 | Upon Request | 0.63 | 20 | 196 |

| MW65-30 | 65 | 30 | 12~16 | Upon Request | 0.75 | 26 | 255 |

| MW65-40 | 65 | 40 | 12~16 | Upon Request | 1 | 38 | 372 |

| MW65-50 | 65 | 50 | 12~16 | Upon Request | 1.25 | 50 | 490 |

| MW80-25 | 80 | 25 | 10~16 | Upon Request | 0.8 | 40 | 392 |

| MW80-30 | 80 | 30 | 10~16 | Upon Request | 0.96 | 46 | 451 |

| MW80-40 | 80 | 40 | 10~16 | Upon Request | 1.28 | 58 | 568 |

| MW80-50 | 80 | 50 | 10~16 | Upon Request | 1.6 | 70 | 686 |

| MW90-25 | 90 | 25 | 12~16 | Upon Request | 1.19 | 50 | 490 |

| MW90-30 | 90 | 30 | 12~16 | Upon Request | 1.43 | 58 | 564 |

| MW90-40 | 90 | 40 | 12~16 | Upon Request | 1.9 | 73 | 711 |

| MW90-50 | 90 | 50 | 12~16 | Upon Request | 2.38 | 88 | 858 |

| MW100-25 | 100 | 25 | 12~16 | Upon Request | 1.6 | 50 | 490 |

| MW100-30 | 100 | 30 | 12~16 | Upon Request | 1.92 | 63 | 613 |

| MW100-40 | 100 | 40 | 12~16 | Upon Request | 2.56 | 88 | 858 |

| MW100-45 | 100 | 45 | 12~16 | Upon Request | 2.88 | 100 | 980 |

| MW110-30 | 110 | 30 | 16~20 | Upon Request | 2.1 | 55 | 539 |

| MW110-40 | 110 | 40 | 16~20 | Upon Request | 2.8 | 77 | 751 |

| MW110-50 | 110 | 50 | 16~20 | Upon Request | 3.5 | 98 | 964 |

| MW110-60 | 110 | 60 | 16~20 | Upon Request | 4.2 | 120 | 1176 |

| MW120-30 | 120 | 30 | 20~26 | Upon Request | 2.2 | 60 | 588 |

| MW120-40 | 120 | 40 | 20~26 | Upon Request | 2.95 | 80 | 784 |

| MW120-50 | 120 | 50 | 20~26 | Upon Request | 3.7 | 100 | 980 |

| MW120-60 | 120 | 60 | 20~26 | Upon Request | 4.4 | 120 | 1176 |

| MW125-30 | 125 | 30 | 20~26 | Upon Request | 2.3 | 65 | 637 |

| MW125-40 | 125 | 40 | 20~26 | Upon Request | 3.07 | 90 | 882 |

| MW125-50 | 125 | 50 | 20~26 | Upon Request | 3.83 | 115 | 1127 |

| MW125-60 | 125 | 60 | 20~26 | Upon Request | 4.6 | 140 | 1372 |

| MW130-30 | 130 | 30 | 20~28 | Upon Request | 2.5 | 70 | 686 |

| MW130-40 | 130 | 40 | 20~28 | Upon Request | 3.35 | 100 | 980 |

| MW130-50 | 130 | 50 | 20~28 | Upon Request | 4.2 | 130 | 1274 |

| MW130-60 | 130 | 60 | 20~28 | Upon Request | 5 | 160 | 1568 |

| MW150-30 | 150 | 30 | 26~30 | Upon Request | 4.4 | 80 | 784 |

| MW150-40 | 150 | 40 | 26~30 | Upon Request | 5.8 | 112 | 1098 |

| MW150-50 | 150 | 50 | 26~30 | Upon Request | 7.3 | 144 | 1411 |

| MW150-55 | 150 | 55 | 26~30 | Upon Request | 8 | 160 | 1568 |

| MW160-30 | 160 | 30 | 26~32 | Upon Request | 5.8 | 90 | 882 |

| MW160-40 | 160 | 40 | 26~32 | Upon Request | 7.8 | 125 | 1225 |

| MW160-50 | 160 | 50 | 26~32 | Upon Request | 9.8 | 160 | 1568 |

| MW160-60 | 160 | 60 | 26~32 | Upon Request | 11.8 | 195 | 1911 |

| MW180-30 | 180 | 30 | 28~36 | Upon Request | 9.2 | 100 | 980 |

| MW180-40 | 180 | 40 | 28~36 | Upon Request | 12.3 | 140 | 1372 |

| MW180-50 | 180 | 50 | 28~36 | Upon Request | 15.3 | 180 | 1764 |

| MW180-60 | 180 | 60 | 28~36 | Upon Request | 18.4 | 220 | 2156 |

| MW200-30 | 200 | 30 | 30~40 | Upon Request | 11 | 120 | 1176 |

| MW200-40 | 200 | 40 | 30~40 | Upon Request | 14.7 | 173 | 1699 |

| MW200-50 | 200 | 50 | 30~40 | Upon Request | 18.33 | 227 | 2221 |

| MW200-60 | 200 | 60 | 30~40 | Upon Request | 22 | 280 | 2744 |

| PN | D (in) | W (in) | S (in) | B & H | Self-Wt (lbs) | Pull Force (lbf) | Pull Force (N) |

|---|---|---|---|---|---|---|---|

| MW40-25 | 1.57 | 0.98 | 0.31 | Upon Request | 0.62 | 18 | 78 |

| MW50-25 | 1.97 | 0.98 | 0.31~0.47 | Upon Request | 0.88 | 22 | 98 |

| MW50-30 | 1.97 | 1.18 | 0.31~0.47 | Upon Request | 1.06 | 31 | 137 |

| MW50-40 | 1.97 | 1.57 | 0.31~0.47 | Upon Request | 1.41 | 49 | 216 |

| MW50-50 | 1.97 | 1.97 | 0.31~0.47 | Upon Request | 1.76 | 66 | 294 |

| MW60-25 | 2.36 | 0.98 | 0.31~0.47 | Upon Request | 1.3 | 33 | 147 |

| MW60-30 | 2.36 | 1.18 | 0.31~0.47 | Upon Request | 1.57 | 42 | 186 |

| MW60-40 | 2.36 | 1.57 | 0.31~0.47 | Upon Request | 2.09 | 60 | 265 |

| MW60-50 | 2.36 | 1.97 | 0.31~0.47 | Upon Request | 2.6 | 77 | 343 |

| MW65-25 | 2.56 | 0.98 | 0.47~0.63 | Upon Request | 1.39 | 44 | 196 |

| MW65-30 | 2.56 | 1.18 | 0.47~0.63 | Upon Request | 1.65 | 57 | 255 |

| MW65-40 | 2.56 | 1.57 | 0.47~0.63 | Upon Request | 2.2 | 84 | 372 |

| MW65-50 | 2.56 | 1.97 | 0.47~0.63 | Upon Request | 2.76 | 110 | 490 |

| MW80-25 | 3.15 | 0.98 | 0.39~0.63 | Upon Request | 1.76 | 88 | 392 |

| MW80-30 | 3.15 | 1.18 | 0.39~0.63 | Upon Request | 2.12 | 101 | 451 |

| MW80-40 | 3.15 | 1.57 | 0.39~0.63 | Upon Request | 2.82 | 128 | 568 |

| MW80-50 | 3.15 | 1.97 | 0.39~0.63 | Upon Request | 3.53 | 154 | 686 |

| MW90-25 | 3.54 | 0.98 | 0.47~0.63 | Upon Request | 2.62 | 110 | 490 |

| MW90-30 | 3.54 | 1.18 | 0.47~0.63 | Upon Request | 3.15 | 128 | 564 |

| MW90-40 | 3.54 | 1.57 | 0.47~0.63 | Upon Request | 4.19 | 161 | 711 |

| MW90-50 | 3.54 | 1.97 | 0.47~0.63 | Upon Request | 5.25 | 194 | 858 |

| MW100-25 | 3.94 | 0.98 | 0.47~0.63 | Upon Request | 3.53 | 110 | 490 |

| MW100-30 | 3.94 | 1.18 | 0.47~0.63 | Upon Request | 4.23 | 139 | 613 |

| MW100-40 | 3.94 | 1.57 | 0.47~0.63 | Upon Request | 5.64 | 194 | 858 |

| MW100-45 | 3.94 | 1.77 | 0.47~0.63 | Upon Request | 6.35 | 221 | 980 |

| MW110-30 | 4.33 | 1.18 | 0.63~0.79 | Upon Request | 4.63 | 121 | 539 |

| MW110-40 | 4.33 | 1.57 | 0.63~0.79 | Upon Request | 6.17 | 170 | 751 |

| MW110-50 | 4.33 | 1.97 | 0.63~0.79 | Upon Request | 7.72 | 216 | 964 |

| MW110-60 | 4.33 | 2.36 | 0.63~0.79 | Upon Request | 9.26 | 265 | 1176 |

| MW120-30 | 4.72 | 1.18 | 0.79~1.02 | Upon Request | 4.85 | 132 | 588 |

| MW120-40 | 4.72 | 1.57 | 0.79~1.02 | Upon Request | 6.5 | 176 | 784 |

| MW120-50 | 4.72 | 1.97 | 0.79~1.02 | Upon Request | 8.16 | 221 | 980 |

| MW120-60 | 4.72 | 2.36 | 0.79~1.02 | Upon Request | 9.7 | 265 | 1176 |

| MW125-30 | 4.92 | 1.18 | 0.79~1.02 | Upon Request | 5.07 | 143 | 637 |

| MW125-40 | 4.92 | 1.57 | 0.79~1.02 | Upon Request | 6.77 | 198 | 882 |

| MW125-50 | 4.92 | 1.97 | 0.79~1.02 | Upon Request | 8.44 | 254 | 1127 |

| MW125-60 | 4.92 | 2.36 | 0.79~1.02 | Upon Request | 10.14 | 309 | 1372 |

| MW130-30 | 5.12 | 1.18 | 0.79~1.10 | Upon Request | 5.51 | 154 | 686 |

| MW130-40 | 5.12 | 1.57 | 0.79~1.10 | Upon Request | 7.39 | 221 | 980 |

| MW130-50 | 5.12 | 1.97 | 0.79~1.10 | Upon Request | 9.26 | 287 | 1274 |

| MW130-60 | 5.12 | 2.36 | 0.79~1.10 | Upon Request | 11.02 | 353 | 1568 |

| MW150-30 | 5.91 | 1.18 | 1.02~1.18 | Upon Request | 9.7 | 176 | 784 |

| MW150-40 | 5.91 | 1.57 | 1.02~1.18 | Upon Request | 12.79 | 247 | 1098 |

| MW150-50 | 5.91 | 1.97 | 1.02~1.18 | Upon Request | 16.09 | 317 | 1411 |

| MW150-55 | 5.91 | 2.17 | 1.02~1.18 | Upon Request | 17.64 | 353 | 1568 |

| MW160-30 | 6.3 | 1.18 | 1.02~1.26 | Upon Request | 12.79 | 198 | 882 |

| MW160-40 | 6.3 | 1.57 | 1.02~1.26 | Upon Request | 17.2 | 276 | 1225 |

| MW160-50 | 6.3 | 1.97 | 1.02~1.26 | Upon Request | 21.6 | 353 | 1568 |

| MW160-60 | 6.3 | 2.36 | 1.02~1.26 | Upon Request | 26.01 | 430 | 1911 |

| MW180-30 | 7.09 | 1.18 | 1.10~1.42 | Upon Request | 20.28 | 221 | 980 |

| MW180-40 | 7.09 | 1.57 | 1.10~1.42 | Upon Request | 27.12 | 309 | 1372 |

| MW180-50 | 7.09 | 1.97 | 1.10~1.42 | Upon Request | 33.73 | 397 | 1764 |

| MW180-60 | 7.09 | 2.36 | 1.10~1.42 | Upon Request | 40.56 | 485 | 2156 |

| MW200-30 | 7.87 | 1.18 | 1.18~1.57 | Upon Request | 24.25 | 265 | 1176 |

| MW200-40 | 7.87 | 1.57 | 1.18~1.57 | Upon Request | 32.41 | 381 | 1699 |

| MW200-50 | 7.87 | 1.97 | 1.18~1.57 | Upon Request | 40.41 | 500 | 2221 |

| MW200-60 | 7.87 | 2.36 | 1.18~1.57 | Upon Request | 48.5 | 617 | 2744 |

| PN | D (in) | W (in) | S (in) | B & H | Self-Wt (lbs) | Pull Force (lbf) | Pull Force (N) |

|---|---|---|---|---|---|---|---|

| MW40-25 | 1.57 | 0.98 | 0.31 | Upon Request | 0.62 | 18 | 78 |

| MW50-25 | 1.97 | 0.98 | 0.31~0.47 | Upon Request | 0.88 | 22 | 98 |

| MW50-30 | 1.97 | 1.18 | 0.31~0.47 | Upon Request | 1.06 | 31 | 137 |

| MW50-40 | 1.97 | 1.57 | 0.31~0.47 | Upon Request | 1.41 | 49 | 216 |

| MW50-50 | 1.97 | 1.97 | 0.31~0.47 | Upon Request | 1.76 | 66 | 294 |

| MW60-25 | 2.36 | 0.98 | 0.31~0.47 | Upon Request | 1.3 | 33 | 147 |

| MW60-30 | 2.36 | 1.18 | 0.31~0.47 | Upon Request | 1.57 | 42 | 186 |

| MW60-40 | 2.36 | 1.57 | 0.31~0.47 | Upon Request | 2.09 | 60 | 265 |

| MW60-50 | 2.36 | 1.97 | 0.31~0.47 | Upon Request | 2.6 | 77 | 343 |

| MW65-25 | 2.56 | 0.98 | 0.47~0.63 | Upon Request | 1.39 | 44 | 196 |

| MW65-30 | 2.56 | 1.18 | 0.47~0.63 | Upon Request | 1.65 | 57 | 255 |

| MW65-40 | 2.56 | 1.57 | 0.47~0.63 | Upon Request | 2.2 | 84 | 372 |

| MW65-50 | 2.56 | 1.97 | 0.47~0.63 | Upon Request | 2.76 | 110 | 490 |

| MW80-25 | 3.15 | 0.98 | 0.39~0.63 | Upon Request | 1.76 | 88 | 392 |

| MW80-30 | 3.15 | 1.18 | 0.39~0.63 | Upon Request | 2.12 | 101 | 451 |

| MW80-40 | 3.15 | 1.57 | 0.39~0.63 | Upon Request | 2.82 | 128 | 568 |

| MW80-50 | 3.15 | 1.97 | 0.39~0.63 | Upon Request | 3.53 | 154 | 686 |

| MW90-25 | 3.54 | 0.98 | 0.47~0.63 | Upon Request | 2.62 | 110 | 490 |

| MW90-30 | 3.54 | 1.18 | 0.47~0.63 | Upon Request | 3.15 | 128 | 564 |

| MW90-40 | 3.54 | 1.57 | 0.47~0.63 | Upon Request | 4.19 | 161 | 711 |

| MW90-50 | 3.54 | 1.97 | 0.47~0.63 | Upon Request | 5.25 | 194 | 858 |

| MW100-25 | 3.94 | 0.98 | 0.47~0.63 | Upon Request | 3.53 | 110 | 490 |

| MW100-30 | 3.94 | 1.18 | 0.47~0.63 | Upon Request | 4.23 | 139 | 613 |

| MW100-40 | 3.94 | 1.57 | 0.47~0.63 | Upon Request | 5.64 | 194 | 858 |

| MW100-45 | 3.94 | 1.77 | 0.47~0.63 | Upon Request | 6.35 | 221 | 980 |

| MW110-30 | 4.33 | 1.18 | 0.63~0.79 | Upon Request | 4.63 | 121 | 539 |

| MW110-40 | 4.33 | 1.57 | 0.63~0.79 | Upon Request | 6.17 | 170 | 751 |

| MW110-50 | 4.33 | 1.97 | 0.63~0.79 | Upon Request | 7.72 | 216 | 964 |

| MW110-60 | 4.33 | 2.36 | 0.63~0.79 | Upon Request | 9.26 | 265 | 1176 |

| MW120-30 | 4.72 | 1.18 | 0.79~1.02 | Upon Request | 4.85 | 132 | 588 |

| MW120-40 | 4.72 | 1.57 | 0.79~1.02 | Upon Request | 6.5 | 176 | 784 |

| MW120-50 | 4.72 | 1.97 | 0.79~1.02 | Upon Request | 8.16 | 221 | 980 |

| MW120-60 | 4.72 | 2.36 | 0.79~1.02 | Upon Request | 9.7 | 265 | 1176 |

| MW125-30 | 4.92 | 1.18 | 0.79~1.02 | Upon Request | 5.07 | 143 | 637 |

| MW125-40 | 4.92 | 1.57 | 0.79~1.02 | Upon Request | 6.77 | 198 | 882 |

| MW125-50 | 4.92 | 1.97 | 0.79~1.02 | Upon Request | 8.44 | 254 | 1127 |

| MW125-60 | 4.92 | 2.36 | 0.79~1.02 | Upon Request | 10.14 | 309 | 1372 |

| MW130-30 | 5.12 | 1.18 | 0.79~1.10 | Upon Request | 5.51 | 154 | 686 |

| MW130-40 | 5.12 | 1.57 | 0.79~1.10 | Upon Request | 7.39 | 221 | 980 |

| MW130-50 | 5.12 | 1.97 | 0.79~1.10 | Upon Request | 9.26 | 287 | 1274 |

| MW130-60 | 5.12 | 2.36 | 0.79~1.10 | Upon Request | 11.02 | 353 | 1568 |

| MW150-30 | 5.91 | 1.18 | 1.02~1.18 | Upon Request | 9.7 | 176 | 784 |

| MW150-40 | 5.91 | 1.57 | 1.02~1.18 | Upon Request | 12.79 | 247 | 1098 |

| MW150-50 | 5.91 | 1.97 | 1.02~1.18 | Upon Request | 16.09 | 317 | 1411 |

| MW150-55 | 5.91 | 2.17 | 1.02~1.18 | Upon Request | 17.64 | 353 | 1568 |

| MW160-30 | 6.3 | 1.18 | 1.02~1.26 | Upon Request | 12.79 | 198 | 882 |

| MW160-40 | 6.3 | 1.57 | 1.02~1.26 | Upon Request | 17.2 | 276 | 1225 |

| MW160-50 | 6.3 | 1.97 | 1.02~1.26 | Upon Request | 21.6 | 353 | 1568 |

| MW160-60 | 6.3 | 2.36 | 1.02~1.26 | Upon Request | 26.01 | 430 | 1911 |

| MW180-30 | 7.09 | 1.18 | 1.10~1.42 | Upon Request | 20.28 | 221 | 980 |

| MW180-40 | 7.09 | 1.57 | 1.10~1.42 | Upon Request | 27.12 | 309 | 1372 |

| MW180-50 | 7.09 | 1.97 | 1.10~1.42 | Upon Request | 33.73 | 397 | 1764 |

| MW180-60 | 7.09 | 2.36 | 1.10~1.42 | Upon Request | 40.56 | 485 | 2156 |

| MW200-30 | 7.87 | 1.18 | 1.18~1.57 | Upon Request | 24.25 | 265 | 1176 |

| MW200-40 | 7.87 | 1.57 | 1.18~1.57 | Upon Request | 32.41 | 381 | 1699 |

| MW200-50 | 7.87 | 1.97 | 1.18~1.57 | Upon Request | 40.41 | 500 | 2221 |

| MW200-60 | 7.87 | 2.36 | 1.18~1.57 | Upon Request | 48.5 | 617 | 2744 |

Nota:

- Sobre la carga vertical colgante, Los datos de la tabla son muy conservadores. Por ejemplo, los datos probados para MW50-25 son de 13,5 kgf, pero nosotros indicamos 12 kgs. Los datos probados para MW180-30 son 151 kgf, pero la tabla indica 100 kgs. Más información sobre cómo funciona el cálculo de la rueda magnética del robot.

- S, H y B se basan en las necesidades del cliente y el cliente las especifica por completo. El valor S es nuestro rango de diámetros recomendado; pero el diámetro final lo especifica el cliente.

- Todos los tamaños de ruedas magnéticas colgantes pueden personalizarse con neumáticos de caucho. Los neumáticos de goma se pueden sustituir en cualquier momento.

- Si el tamaño de la rueda magnética que necesita no está en la tabla, también podemos personalizarla basándonos en el dibujo CAD que nos proporcione.

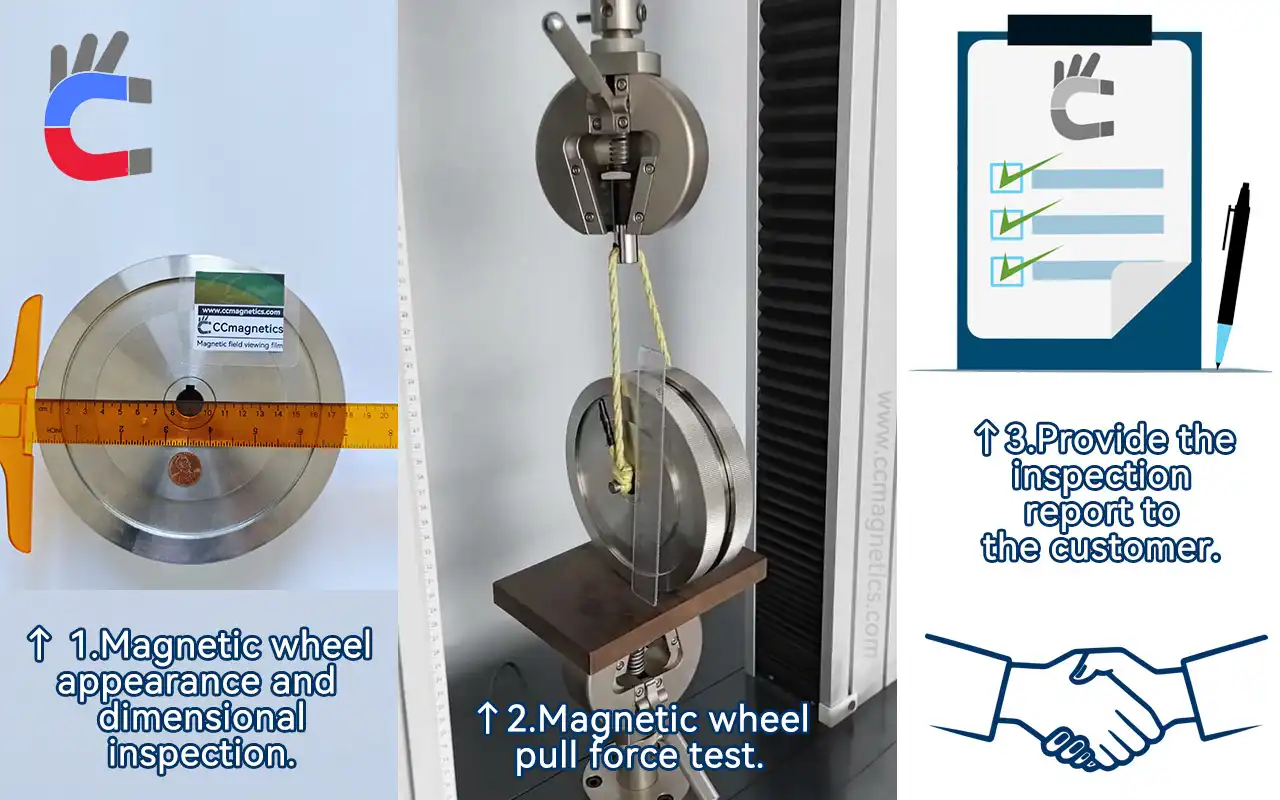

- Proporcionamos a los clientes informes gratuitos de las pruebas de tracción.

Proporcionamos a los clientes informes gratuitos de las pruebas de tracción.

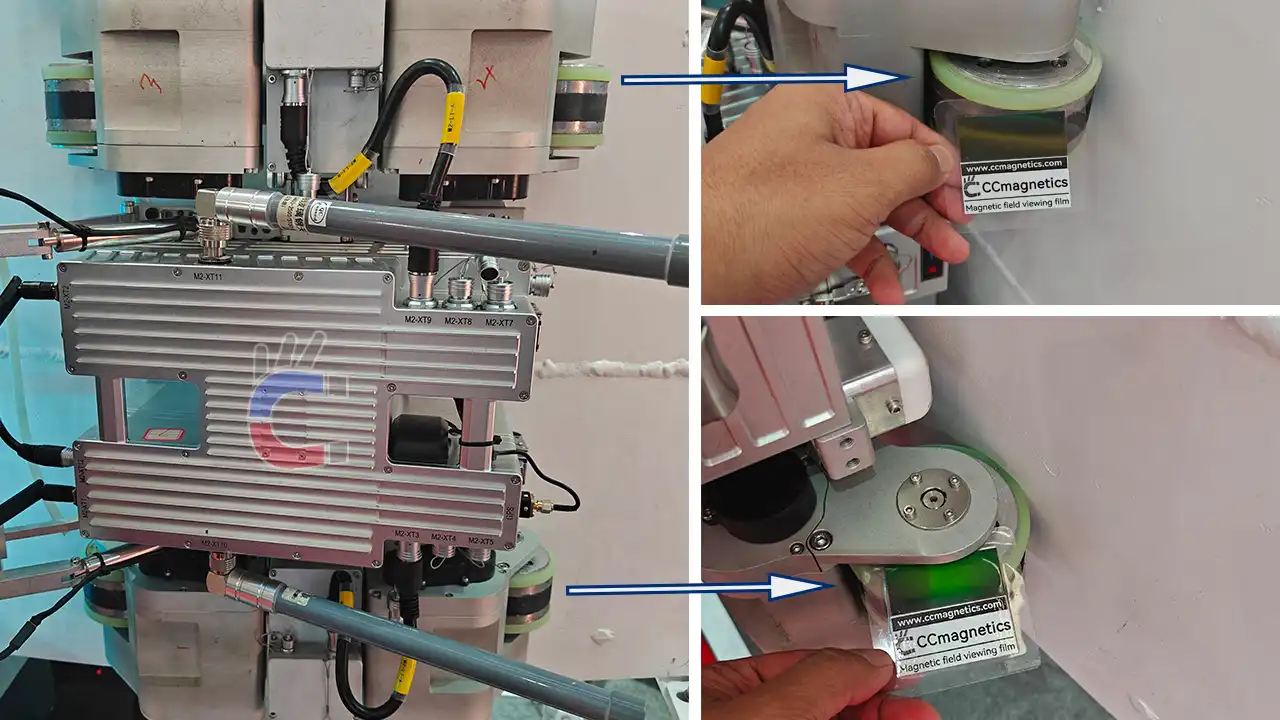

Aplicación:

- Rueda magnética para robot trepamuros

- Barco robot arenador rueda magnética

- Rueda Magnética Robot Escalador

- Rueda Magnética Robot Escalador

- Rueda magnética de neodimio

- Rueda magnética para robot trepador de oleoductos

- Rueda magnética para robot de desoxidación y pintura de buques

- Rueda magnética permanente

Características:

- Fuerte adhesión magnética:Los imanes de neodimio proporcionan un agarre excepcional en superficies ferrosas.

- Opciones de tamaño versátiles: Elija entre una gama de diámetros (40 mm - 200 mm) para adaptarse a las necesidades específicas de su robot.

- Gran capacidad de peso: Soporta robots de hasta 1040 kg (cuando se utilizan en conjuntos de cuatro).

- Tracción personalizable: Mejore el agarre y la estabilidad con anillos de goma antideslizantes opcionales.

- Amplia temperatura de funcionamiento: Funciona de forma fiable en diversos entornos (de -40 °C a 80 °C).

P&R: Ruedas magnéticas para robots trepamuros

Reste el peso total de la rueda magnética del peso total de suspensión de la rueda magnética, que es: (4*90kg) - (4*8,5kg)=326kg.

Entonces 326kg es el peso total del robot.

Opciones de personalización adicionales: Neumáticos de goma personalizados.

English

English Deutsch

Deutsch Русский

Русский Français

Français 한국어

한국어 日本語

日本語

Valoraciones

No hay valoraciones aún.