Product Certifications & Quality Assurance

- Does CCmagnetics' product have ISO certification?

Yes, our products are certified with IATF 16949. This is a global standard for quality management systems in the automotive industry, and it is a significantly more rigorous and higher-level certification than ISO 9000. In addition, for chemical compatibility, our products are made from materials free of hazardous substances, fully complying with both the REACH and RoHS directives. We also hold patents for utility models, which further attests to the innovative design and functionality of our products.

- What is the factory's machining accuracy level (IT grade)?

Our factory primarily achieves a machining accuracy level of IT 7, with a small portion of our products reaching IT 8. IT grades are a classification system for manufacturing tolerances. An IT 7 grade indicates a high level of precision, suitable for demanding applications, while IT 8 is also a respectable level of precision used in many industrial contexts.

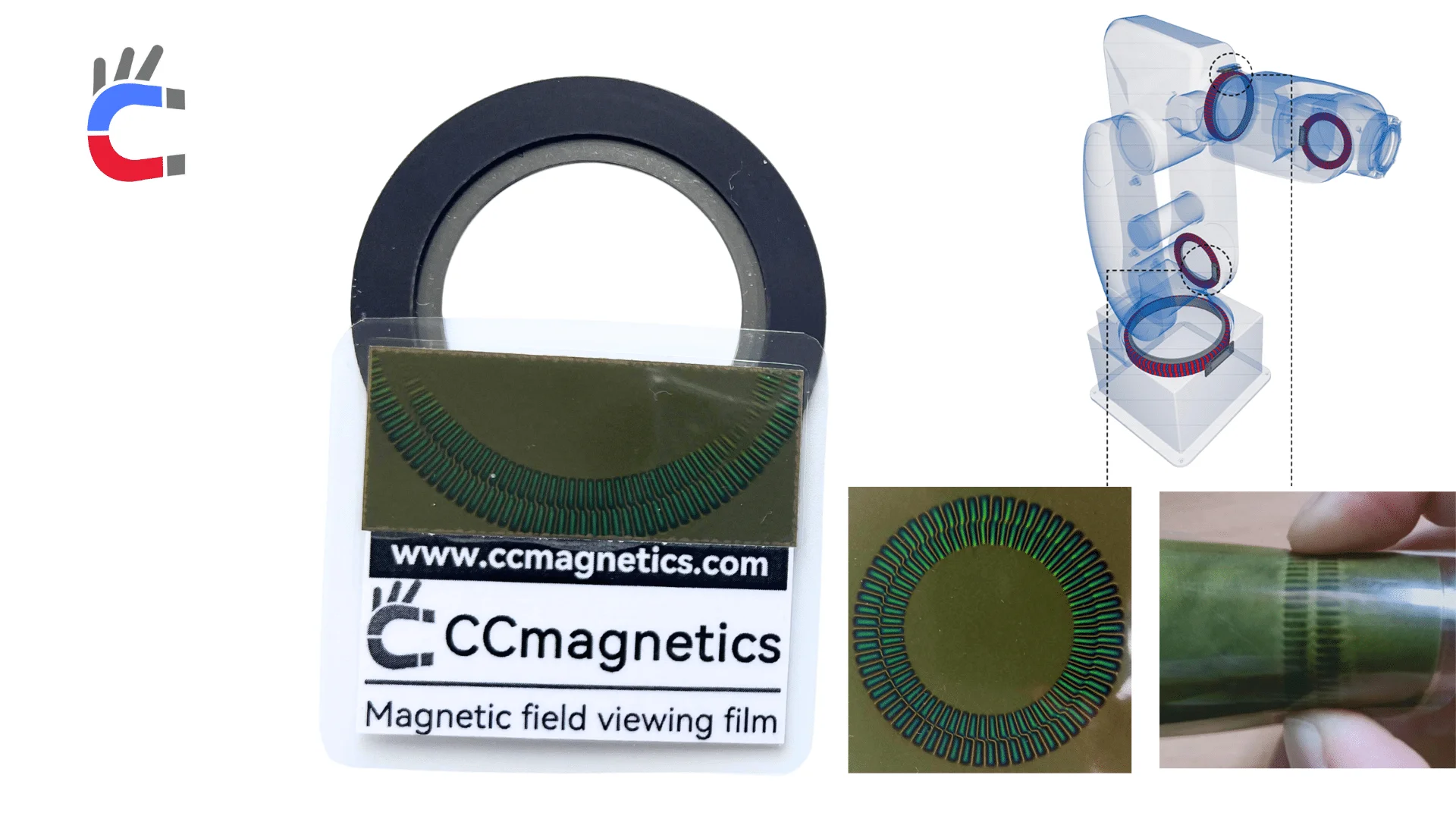

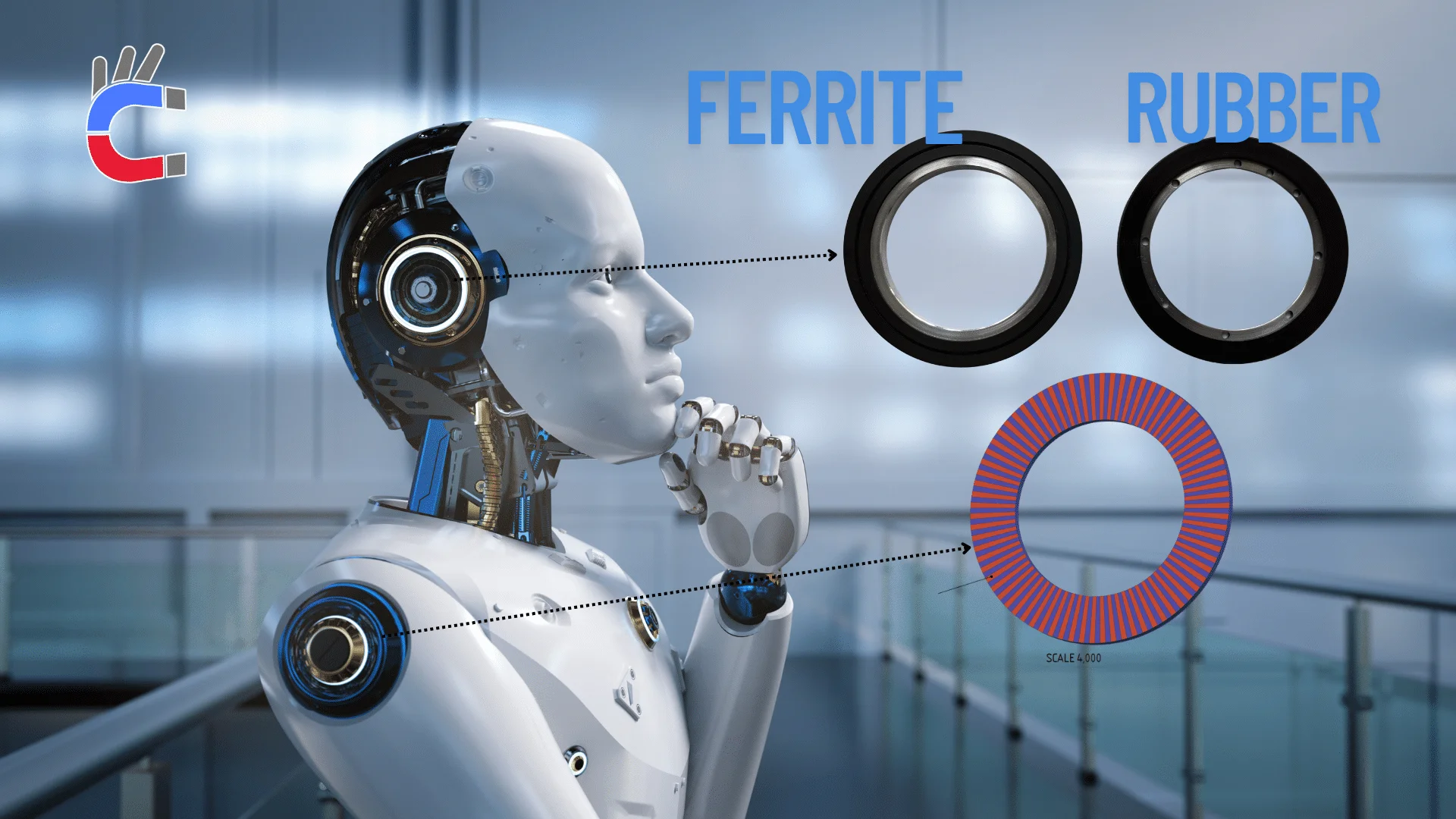

- What is the material of the magnetic core? Is it ferrite powder + nylon or ferrite powder + rubber?

The magnetic core is made from vulcanized rubber, specifically a compound of ferrite powder and rubber. This material choice provides a balance of magnetic properties and mechanical flexibility, making it durable and resistant to impact, unlike more brittle materials like ceramics or nylon-based composites.

Technical Specifications & Performance

- How many magnetic poles correspond to one pulse?

In our system, one pulse corresponds to two magnetic poles. This is a fundamental aspect of how the sensor chip detects and counts the magnetic fields to determine position.

- How can you identify an absolute encoder?

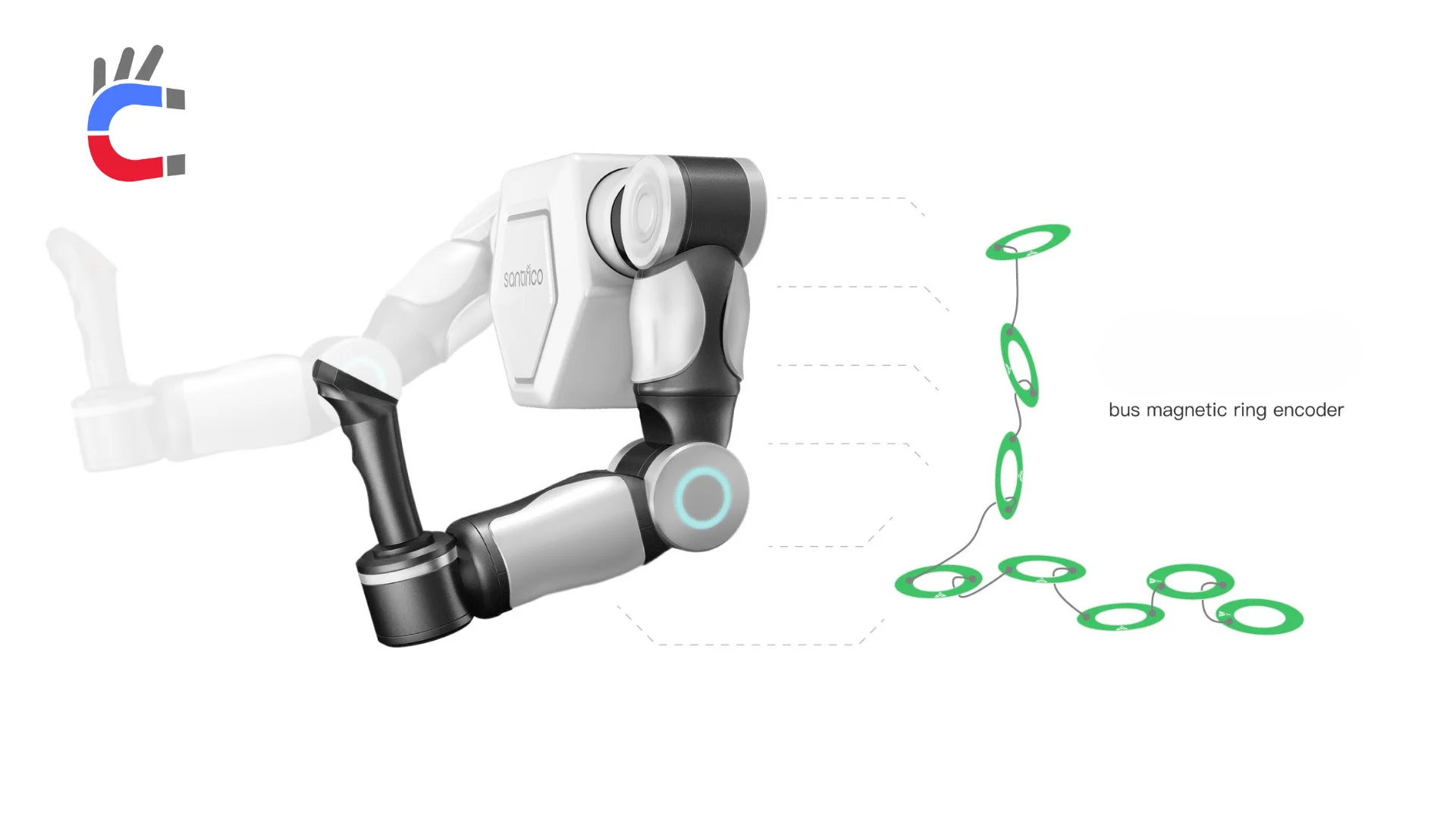

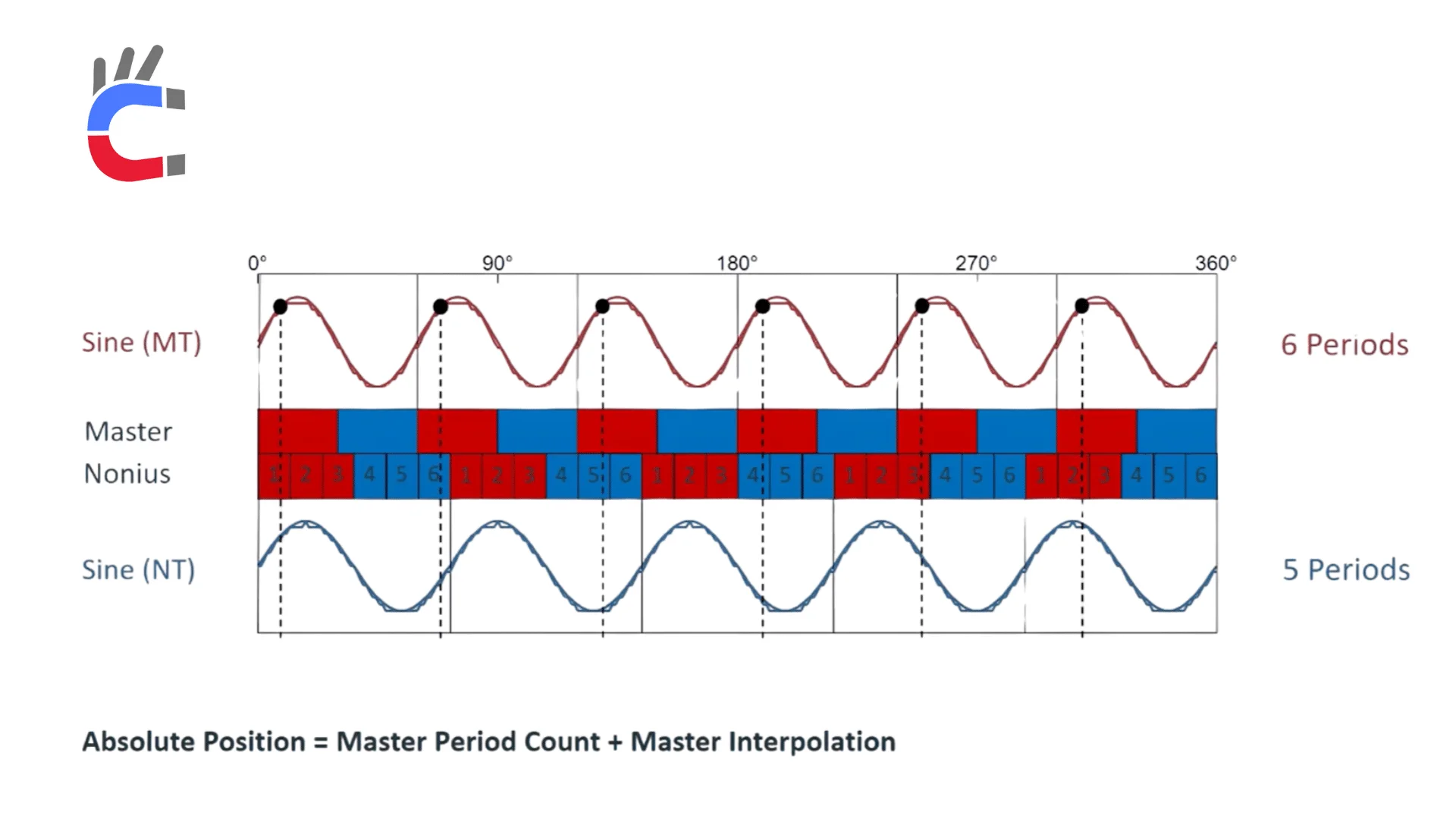

The key distinction lies in the ability to determine position. An incremental encoder only provides relative position changes, so its position is lost upon power-down. An absolute encoder, however, can determine its exact position at any moment. Our products are absolute encoders because they utilize a unique magnetic pattern. The master track and the nonius track are designed with a difference of one magnetic pole pair. This design ensures that the angular difference between the nonius and master tracks is unique at every point around the ring, creating a distinct "code" for each position. For instance, the angular difference is 0° at the starting point and one pole at the 180° mark, accumulating to a full pole pair over a complete 360° rotation. This unique magnetic signature at every location allows for real-time and absolute position sensing.

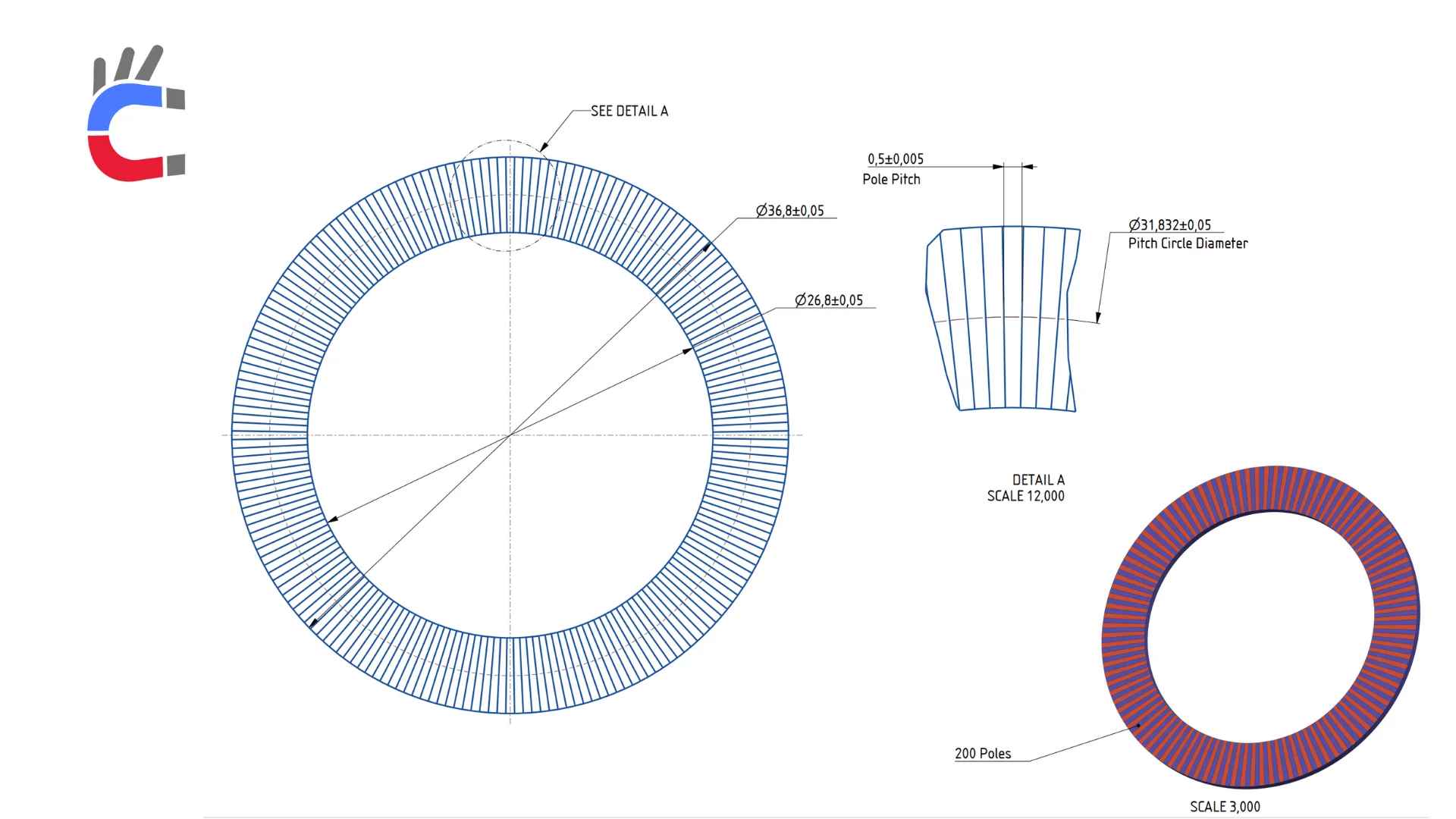

- What is the resolution of the encoder magnetic ring? Is it 18-bit?

Based on the common calculation method, our total system resolution is 19-bit. This is derived by combining the inherent resolution of the magnetic ring itself with the resolution of the sensing chip. Our magnetic ring provides a resolution of 7-bit, which, when integrated with a 12-bit chip, results in a total system resolution of 19 bits (7 + 12). The magnetic ring's resolution, typically between 4 and 7 bits, defines the number of distinct magnetic pole pairs it contains, which is a key factor in the overall system's precision.

- The encoder magnet has a temperature rating of -35°C to 120°C. Can the temperature rating be higher?

While the magnetic material itself can withstand temperatures up to 120°C, the question is not practically relevant. The integrated circuit (IC) sensor chip used in conjunction with the magnetic ring typically ceases to function correctly above 80°C. Therefore, even if the magnet could handle a higher temperature, the system as a whole would fail, making a higher rating for the magnet alone impractical.

- At what air gap are the test data in the product manual measured?

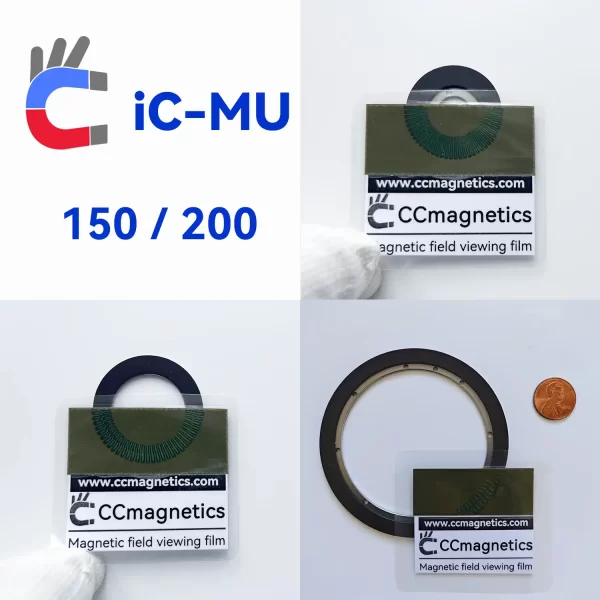

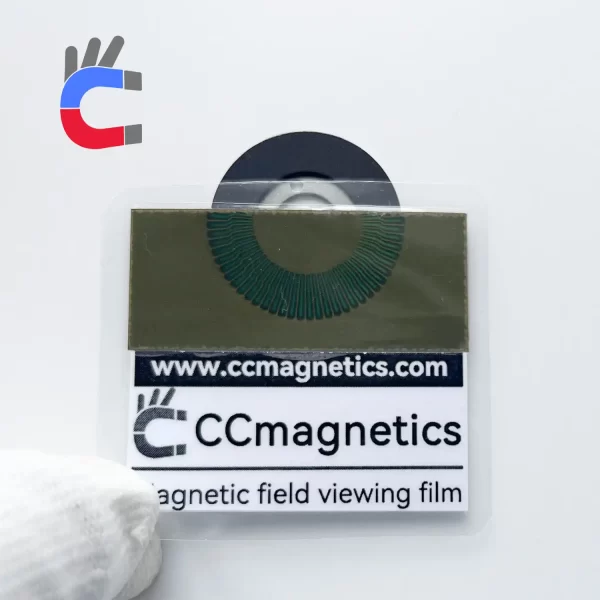

The performance data provided in our product manuals is generally tested at an air gap of 0.4 ± 0.1 mm between the IC chip and the magnetic ring. However, this can vary slightly depending on the specific product model to optimize performance. For example, the MU 128 model is typically tested at 0.3 mm, the MU 150 at 0.4 mm, and the MU 200 at 0.5 mm.

- The R0829 encoder magnetic ring has a magnetic field amplitude of 3 mT at a 0.4 mm air gap. What does 3 mT refer to?

3 mT refers to the peak-to-peak difference in magnetic field strength at the 0.4 mm detection position. This value is the difference between the maximum magnetic field strength (at the peak of a north or south pole) and the minimum magnetic field strength (at the transition point between poles). This differential value is what the sensor chip reads to accurately determine position.

- What is the magnetization method for the encoder magnetic ring?

Our magnetization method is axial magnetization. This is a precise process that uses a pulse-based technique to magnetize one pole at a time. This method ensures high accuracy and consistency in the magnetic pattern, which is crucial for the absolute encoder function.

- Is the magnetizing machine's control standard based on the outer or inner diameter?

The control standard for our magnetizing machine is based on the inner diameter. This ensures consistent and accurate magnetization of the critical inner track, which is essential for the vernier principle of our absolute encoders.

- Can the thickness of the ferrite magnetic ring be 1 mm?

Due to the inherent characteristics of ferrite, it is a brittle material and can easily break upon impact. For this reason, the ferrite rings we produce (not including a metal base) typically have a minimum thickness of 1.4 mm. If a metal base is integrated, the total thickness is generally around 2 mm to ensure sufficient durability and prevent damage during handling or operation.

Production, Lead Time & Support

Encoder magnets

- What is the lead time for encoder magnetic rings?

The lead time depends on our inventory. If the product is in stock, we can ship it within 8 business days. If new production is required, the lead time is 35 business days.

- What is the factory's fixed monthly production capacity?

Our factory's stable monthly production capacity ranges from 30,000 to 40,000 units.

- What is the factory's production method? Is it vulcanization?

We utilize two distinct production methods. The first is vulcanization molding, which is an integrated, one-piece forming process. The second is the magnetic sheet lamination method, where a pre-existing 1.1 mm thick magnetic sheet is adhered to a customer-provided metal base. The lead times and costs for these two methods are different, with the lamination method often being more cost-effective.

- Does the factory provide technical support if we encounter problems during installation or use?

Yes, we provide full technical support. Our products are designed with high precision to meet the demanding requirements of robotics and other high-tech applications. Provided that the correct model and dimensions are chosen for your application, our products are engineered to function without issues. If you encounter issues with technical parameters during installation, please send us the calibration file, and we will assist with the troubleshooting process.

Customization & Product Comparison

- Can you produce encoder magnetic rings with a custom metal base?

Yes, we can. This service is available, but it requires meeting a minimum order quantity (MOQ) and paying the corresponding mold fees. As an alternative, we have designed several models of our magnetic rings with a thickness of 1.1 mm, which are ideal for direct adhesion to a customer's own metal base. This option is often the most cost-effective for both parties.

- If the existing products in the catalog do not meet customer needs, can we get a custom one?

Yes, custom orders are possible. To proceed, customers need to provide detailed design drawings of the encoder magnetic ring. A mold fee is required for this service. The lead time for customized products is typically 10 to 15 days longer than for standard production, as it is influenced by our factory's current order volume and the complexity of the custom design. After the mold fee is paid, we will provide a new production drawing for the customer's final confirmation before manufacturing begins.

- What are the pros and cons of dual-track rubber magnetic rings compared to dual-track ferrite magnetic rings?

The primary difference is in durability and cost. In simple terms, ferrite magnetic rings are more affordable but are brittle and not drop-resistant. In contrast, rubber magnetic rings are more expensive but are highly durable and less prone to damage. Both types of products can meet the high-precision standards required for robotics applications. It's important for customers to understand that products with higher precision often involve more complex manufacturing processes and, therefore, come with a higher price. We encourage customers to consult with us to make a clear and informed choice based on their specific application needs.

- Do all encoder magnetic rings have mounting screw holes?

No, not all products have screw holes for mounting. Some of our products are designed with screw holes, while others are not. For products without screw holes, the most common and effective method for secure installation is to use an adhesive. The critical factor for successful integration is not the mounting method, but rather ensuring that you select a magnetic ring that is compatible with your IC chip and has accurate dimensions.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語