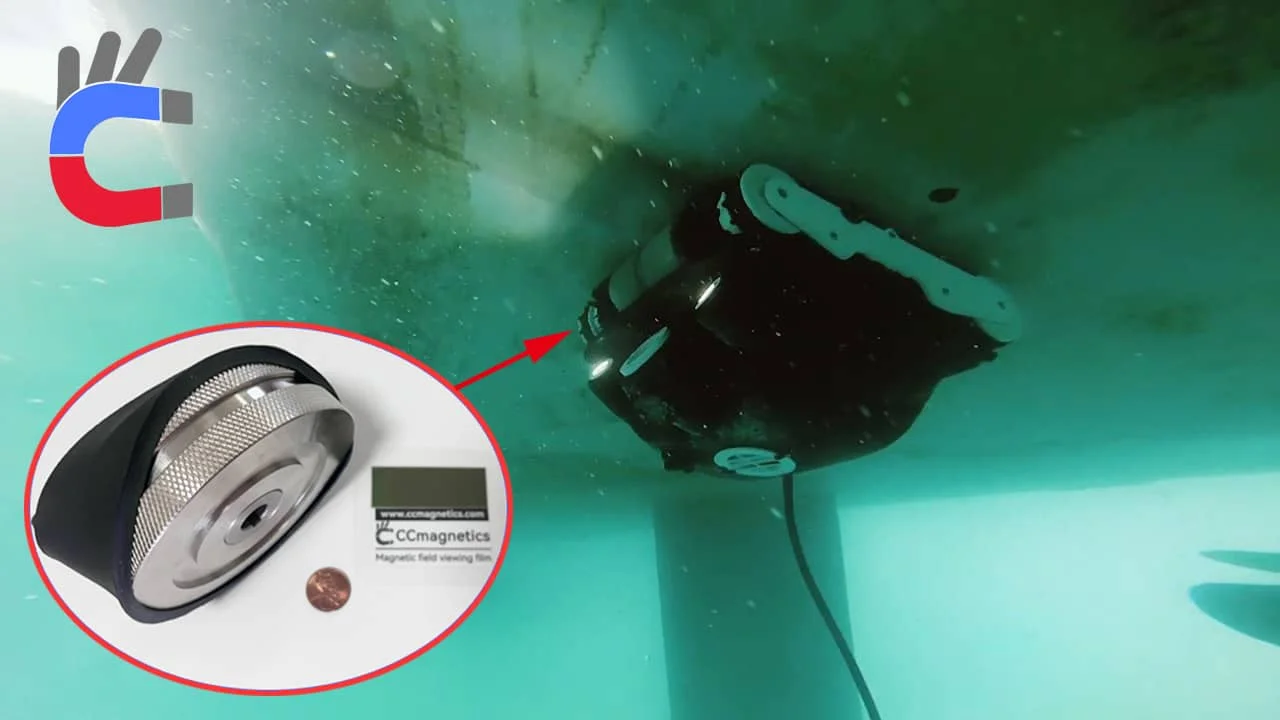

Underwater robots (ROVs or AUVs) play an increasingly vital role in subsea operations. Their ability to perform tasks efficiently and stably largely depends on the performance of their core components. For underwater robots that need to move on metallic surfaces, the choice of magnetic wheels is crucial. This article delves into the key factors to consider when selecting magnetic wheels for underwater robots, helping you make an informed decision.

1. Waterproofing, Corrosion Resistance, and Sealing: The Rigors of the Underwater Environment

The underwater environment is vastly different from that on land, with high pressure and corrosive media (such as salts and various microorganisms in seawater) placing extremely high demands on equipment's waterproofing and corrosion resistance.

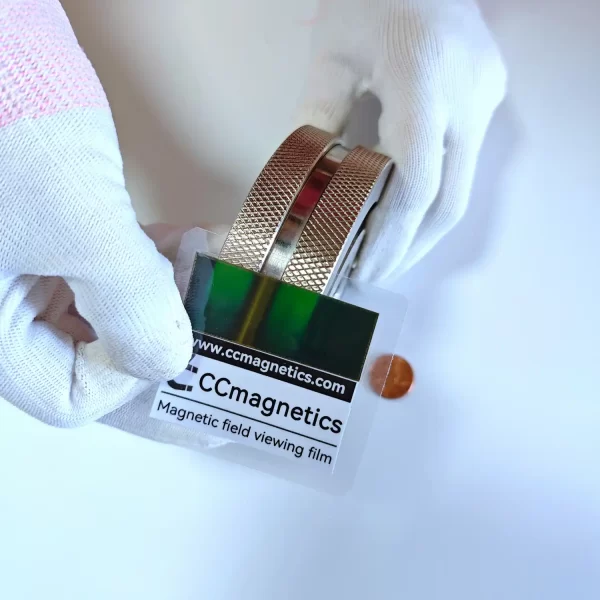

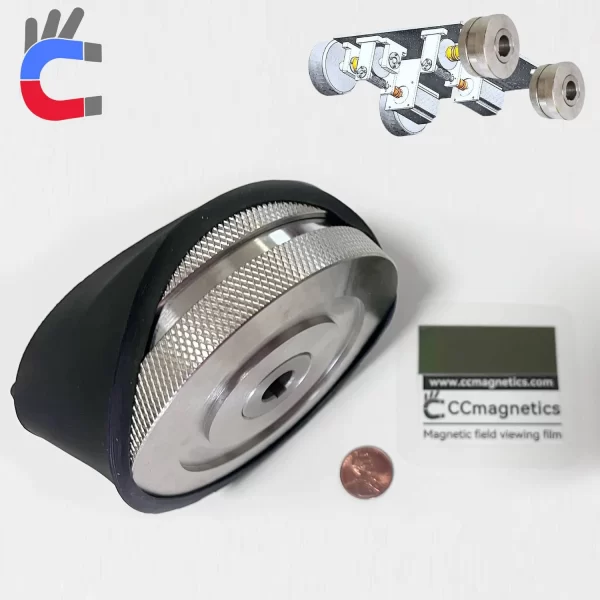

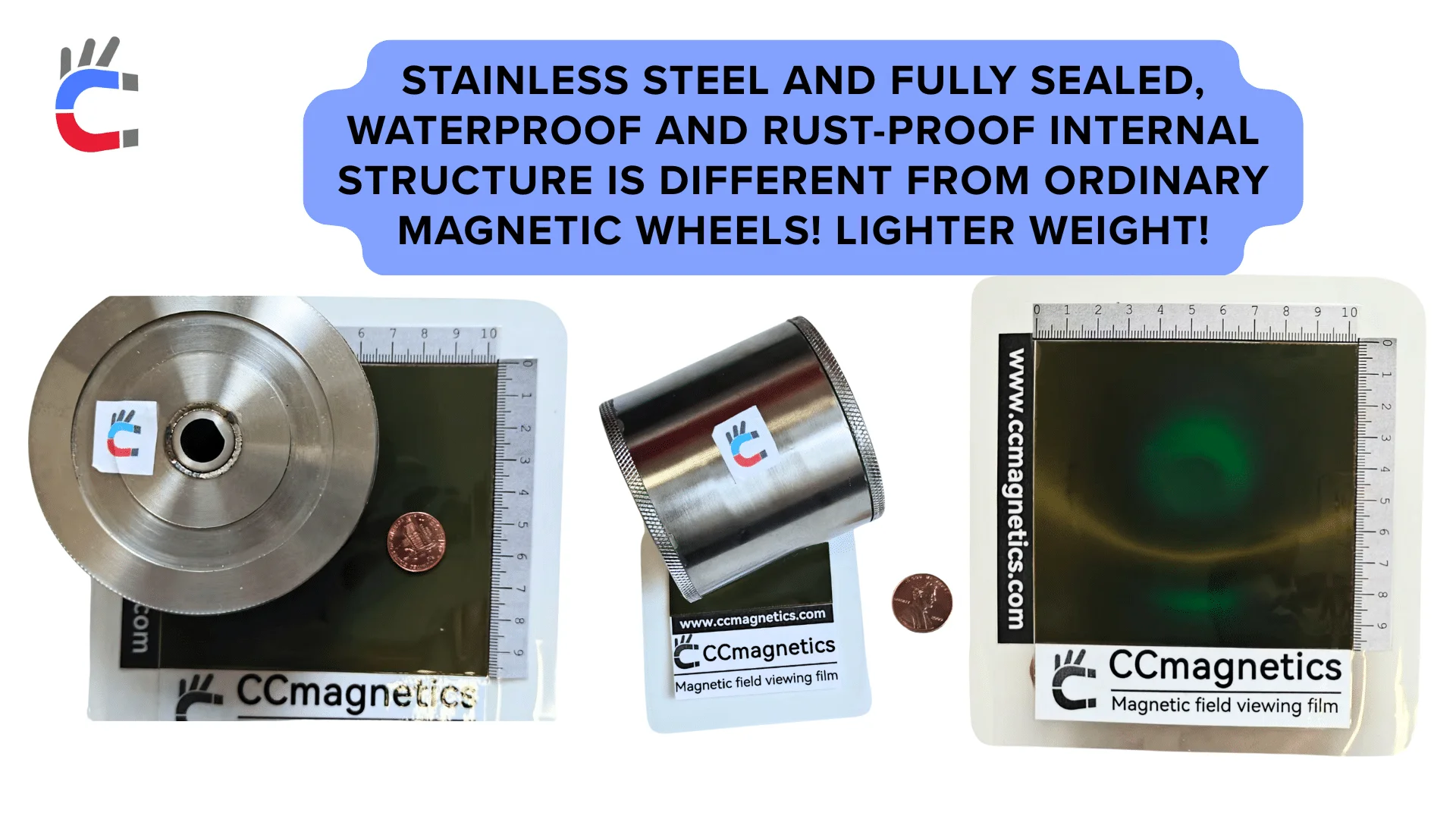

Fully Sealed Structure Design: This is the most basic and critical requirement for underwater magnetic wheels. The magnetic materials and mechanical components inside the magnetic wheel must be completely isolated from water to prevent ingress, which could lead to corrosion, short circuits, or mechanical failure. Techniques like O-rings, ferrofluid seals, or welded seals are commonly used to achieve high-grade waterproofing.

Material Selection: The outer casing and internal components of the magnetic wheel should be made from corrosion-resistant materials, such as stainless steel (especially 316L marine-grade stainless steel), titanium alloy, or engineering plastics. For the magnets themselves, while permanent magnets (like Neodymium-Iron-Boron) offer strong magnetic force, they are highly susceptible to oxidation in wet environments. Therefore, special anti-corrosion treatments are essential, such as epoxy resin encapsulation, nickel-copper-nickel (Ni-Cu-Ni) electroplating, or polymer coatings.

Magnetic Force and Penetration: The underwater environment does not inherently affect the penetration of magnetic force. The strength of the magnetic force depends on the magnet's performance and the magnetic circuit design. However, underwater magnetic wheels may need to deal with hull surfaces covered by biofouling (e.g., barnacles, algae) or coatings. These mediums increase the distance between the magnetic field and the metal surface, thereby weakening the effective adhesion. Therefore, magnetic wheels with sufficiently strong magnetic force are needed to overcome these gaps.

Magnetic Transmission

2. Protective Rubber Sleeves: Preventing Hull Scratches

Whether or not to install a rubber sleeve depends on the application scenario and the requirements for the surface of the object being inspected.

Protecting Hull Paint: For robots that need to adhere to and inspect or clean hull, pipe, or other coated surfaces, the addition of wear-resistant rubber sleeves is crucial. Rubber sleeves can effectively increase friction and prevent the magnetic wheels from directly contacting the hull surface and causing scratches, especially for high-value or easily damaged coatings.

Increasing Friction: Rubber sleeves also significantly increase the coefficient of friction between the magnetic wheel and the contact surface, improving the robot's grip on slippery or fouled surfaces, thereby enhancing mobility stability and climbing ability.

Material and Durability: The material of the rubber sleeve should possess good wear resistance, corrosion resistance, UV resistance, and anti-aging properties to withstand long-term use in the underwater environment.

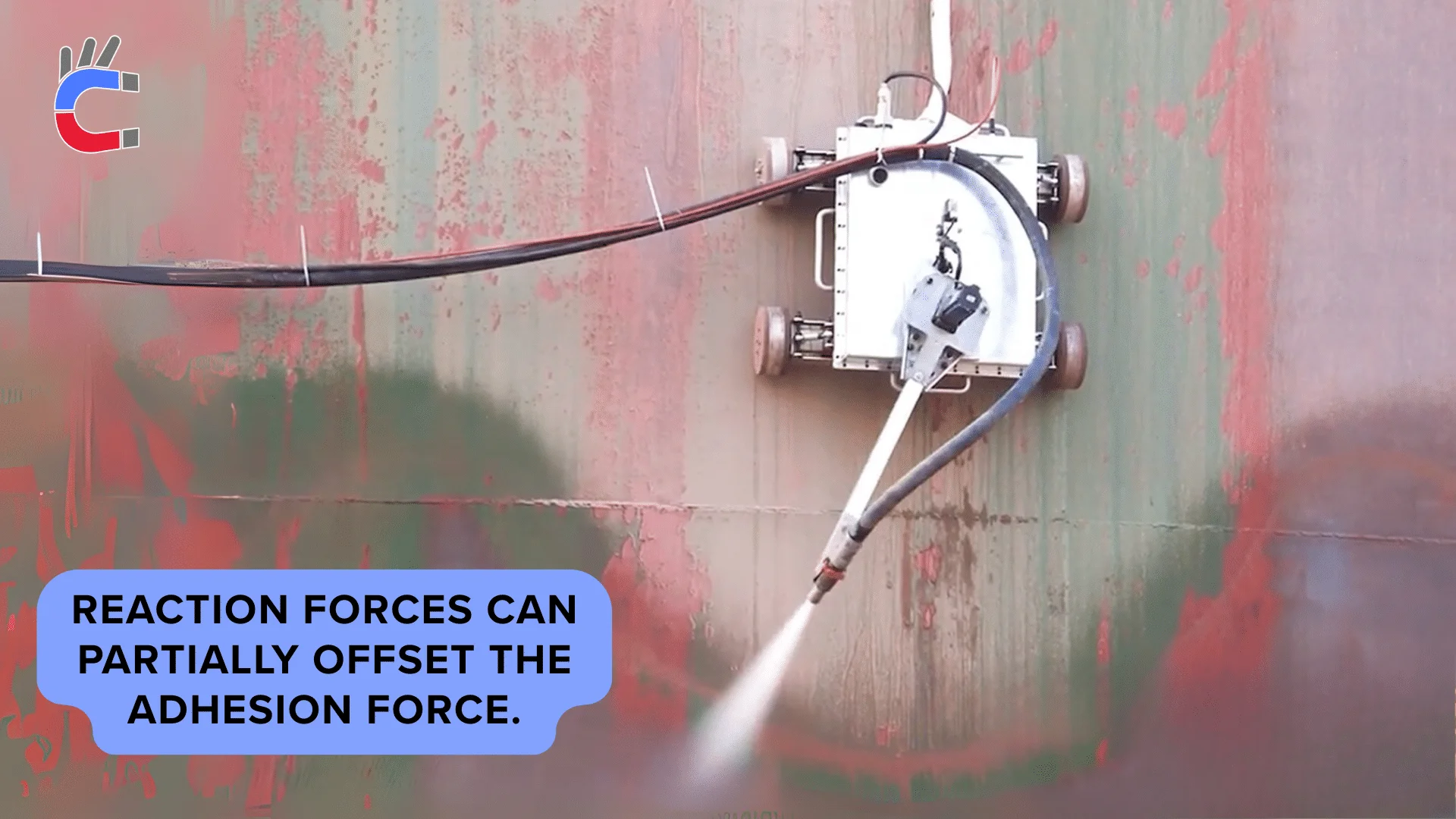

3. Additional Operational Capability and Load Considerations: High-Pressure Water Guns and Grinding Tools

Underwater robots often need to carry various operational tools, and the weight of these tools and the reaction forces generated during operation directly influence the selection of magnetic wheels.

Increased Load: Carrying equipment such as high-pressure water guns, grinding tools, brushes, or sensor arrays significantly increases the robot's overall weight. The magnetic wheel's load capacity must be able to bear the robot's body weight, the weight of all carried tools, and the additional thrust or pull generated during tool operation.

Operational Reaction Forces: Especially when using high-pressure water guns or grinding tools, strong reaction forces are generated, which attempt to push or pull the robot away from the adhered surface. The magnetic wheel's adhesion force must be much greater than these reaction forces to ensure the robot remains stably attached to the surface and completes its task.

Power Consumption and Battery Life: Additional operations not only increase weight but also typically mean higher energy consumption. This affects the robot's battery endurance and needs to be balanced during system design.

4. Buoyancy Design: Positive or Negative Buoyancy?

The robot's buoyancy characteristics significantly impact its underwater movement and operational methods, which are indirectly related to the selection of magnetic wheels.

Positive Buoyancy: Means the robot will naturally float in water.

- Advantages: If power or adhesion is lost, the robot automatically floats to the surface, making recovery easier and reducing the risk of loss.

- Application Scenarios: Suitable for robots that do not require long-term or strong adhesion to underwater structures, or when quick surfacing is needed after operations.

- Impact on Magnetic Wheels: If a positively buoyant robot needs to perform adhesion operations on the bottom or side walls of an underwater structure, the magnetic wheels will need to provide greater upward or lateral adhesion to counteract the buoyancy.

Negative Buoyancy: Means the robot will naturally sink in water.

- Advantages: The robot can more stably descend to the target depth and rely on its own weight to assist adhesion to the top or side walls of underwater structures, reducing the adhesion force required from the magnetic wheels.

- Application Scenarios: Suitable for robots that require long-term operation on underwater structures, or for surveying and maintenance in deep-water environments.

- Impact on Magnetic Wheels: Negative buoyancy helps the robot "press" onto the adhered surface. The primary role of the magnetic wheels is to provide lateral friction for movement and sufficient adhesion when tilted or inverted.

Neutral Buoyancy: Ideally, many underwater robots are designed for neutral buoyancy, meaning they neither float nor sink in water. This minimizes the buoyancy or gravity the robot needs to overcome during underwater movement, thereby reducing the burden on thrusters or magnetic wheels and improving energy efficiency and maneuverability.

- Achieving It: Typically achieved by adjusting the robot's ballast and buoyant materials (e.g., buoyancy modules).

Summary: Buoyancy design directly influences the robot's need for magnetic wheel adhesion. Positively buoyant robots require more adhesion from magnetic wheels to overcome buoyancy, while negatively buoyant robots can utilize gravity to assist adhesion.

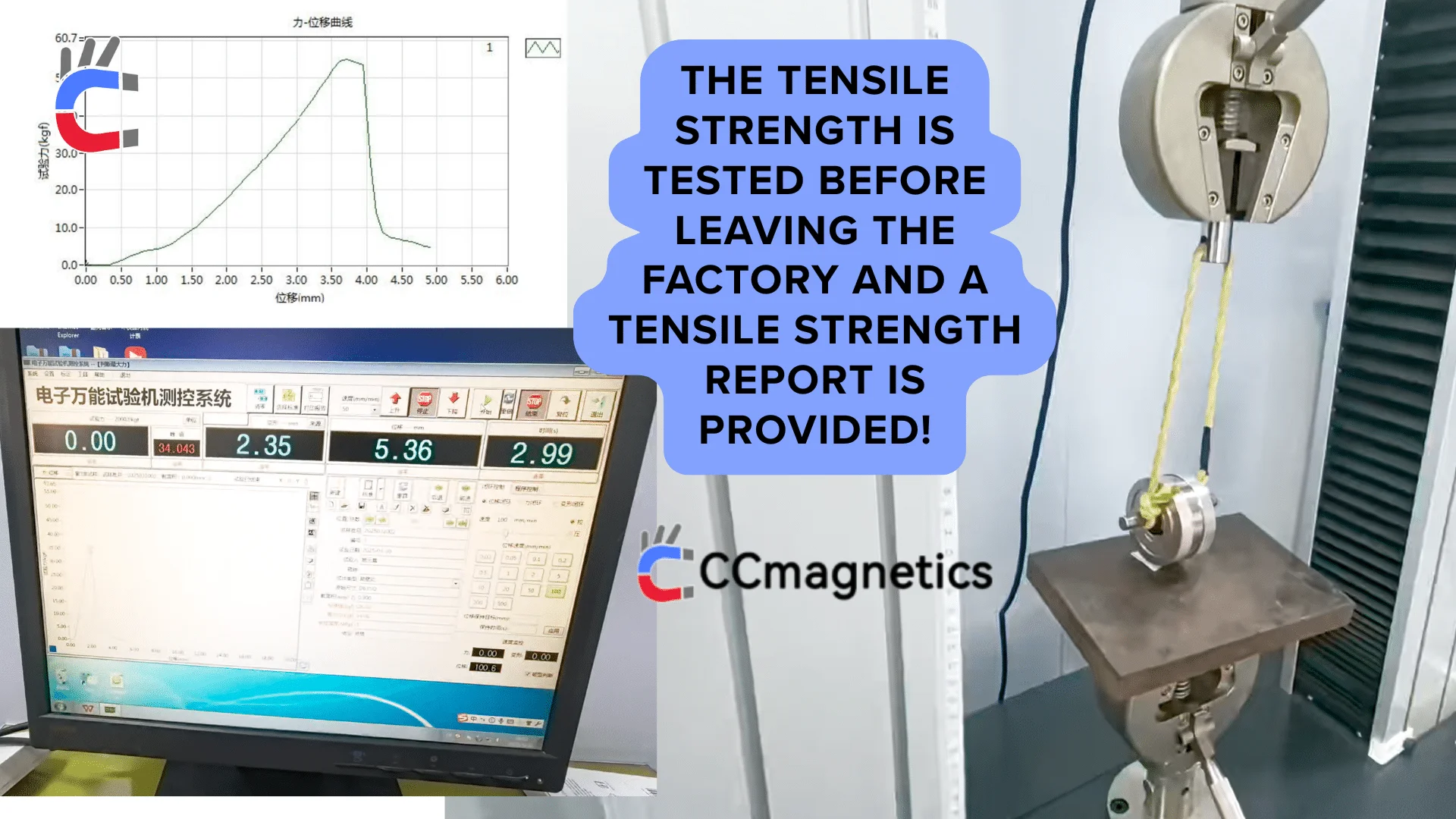

5. Magnetic Wheel Load Capacity: Calculation and Margin

The load capacity of magnetic wheels is a critical indicator of their ability to bear the robot and its mission equipment.

Total Load Calculation: The total load capacity of the magnetic wheels needs to cover the following weights:

- Robot Body Weight: This is the foundational weight.

- Weight of Carried Equipment and Tools: Includes sensors, cameras, manipulators, cleaning tools, etc.

- Magnetic Wheel's Own Weight: For larger diameter magnetic wheels, their self-weight should not be overlooked and should be included in the total load.

Magnet Tools & Accessories

Allow for Safety Margin: In practical applications, due to factors such as uneven surfaces, fouling, and water current impact, the actual adhesion force may decrease. Therefore, when selecting magnetic wheels, their rated load capacity should be significantly greater than the theoretically calculated total weight, typically recommending a safety margin of 20% to 50% or even higher. This means if your robot weighs 100kg, you might need to select magnetic wheels with an adhesion force of 120kg-150kg or even higher.

6. Friction and Motor Load: The Core of Propulsion

The friction of the magnetic wheels directly affects the robot's mobility and determines the required motor power.

Friction and Adhesion: Friction force (Ffriction) is related to the magnetic wheel's adhesion force (Fadhesion) and the coefficient of friction (μ) between the contact surfaces: Ffriction=μ×Fadhesion. A higher coefficient of friction and sufficiently large adhesion force are needed to provide enough friction to ensure stable underwater movement, especially on inclined or vertical surfaces.

Motor Power: If the robot's total weight (including all loads) is significant, or if it needs to overcome large water current resistance or biofouling, then a more powerful drive motor will be required for the robot to move efficiently. Insufficient motor power can lead to slow movement, difficulty climbing, or even inability to move.

Energy Efficiency and Thermal Management: High-power motors mean greater energy consumption, requiring corresponding battery packs. Considerations also need to be made for motor heat dissipation underwater to prevent overheating from affecting performance and lifespan.

Other Factors to Consider

In addition to the core factors mentioned above, the following points are also worth considering when selecting magnetic wheels for underwater robots:

- Size and Weight: The size and weight of the magnetic wheels will affect the robot's overall design, maneuverability, and ease of deployment and recovery. While meeting adhesion requirements, a compact and lightweight design should be prioritized.

- Maintenance and Lifespan: Consider the ease of maintenance and the expected lifespan of the magnetic wheels. Some designs may be easier to replace worn parts or perform regular maintenance.

- Cost: Cost is an unavoidable factor in any project. Choose the most cost-effective solution that meets all performance requirements.

- Customizability: Some special applications may require customized magnetic wheel solutions, such as specific sizes, adhesion forces, or integration of other functions (e.g., sensors).

- Water Current Impact: Underwater robots are often subjected to water currents, especially in strong ocean currents or near underwater structures. The magnetic wheel's adhesion force and the robot's overall streamlined design need to consider how to effectively resist the thrust of water currents.

By comprehensively considering the above factors, you will be able to select the most suitable and reliable magnetic wheels for your underwater robot, thereby ensuring its efficient and safe completion of various tasks in complex underwater environments.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語