In many fields of modern technology, magnetic materials play a pivotal role. Among them, rubber magnets stand out for their unique flexibility, elasticity, and malleability. They not only inherit the magnetic properties of traditional magnetic materials but also achieve diverse shapes and easy processing through a composite with a rubber matrix. Rubber magnets are widely used in various aspects of our daily lives.

The Secret of Rubber Magnets: Materials and Structure

A rubber magnet is essentially a composite material. Its magnetism does not come from the rubber itself but is achieved by filling a rubber matrix with a large number of magnetic powders. These powders are the core of the rubber magnet; they can be magnetized by an external magnetic field and maintain lasting magnetism.

Types and Characteristics of Magnetic Powders

- Metallic Magnetic Powder: Includes iron-cobalt powder, iron-nickel powder, etc. Although they have high magnetic strength, they are expensive and difficult to add, primarily used in precision instruments with extremely high magnetic field requirements.

- Ferrite Powder: Composed of iron oxide and certain bivalent metal compounds, this is currently the most widely used magnetic powder. Its advantages are low cost, easy availability of raw materials, simple manufacturing, and excellent overall performance. For example, high-ferrate is a common ferrite magnetic powder.

In addition to the type of magnetic powder, its particle size and uniformity also have a significant impact on the final product's magnetic strength. Finer and more uniformly distributed magnetic powder can increase the magnetic density and uniformity of the magnetic distribution, thereby enhancing the overall performance of the rubber magnet.

Selection of the Rubber Matrix

The choice of the rubber matrix directly affects the flexibility, wear resistance, aging resistance, and processing performance of the rubber magnet. Common types of rubber include natural rubber, neoprene rubber, and chlorinated polyethylene rubber, each with its own focus:

- Natural Rubber: Has good overall physical and mechanical properties, is easy to process, and can be filled with a large amount of magnetic powder, making it widely used in magnetic rubber.

- Neoprene Rubber: Has a slightly higher magnetic flux and strong molecular polarity, which is conducive to the orderly arrangement of magnetic crystal particles, thus exhibiting greater magnetism.

- Liquid Rubber: Magnetic rubber prepared with liquid rubber as the raw material simplifies the process. Even a small amount of magnetic powder can achieve magnetism similar to that of a high filling amount of dry rubber, showing good development prospects.

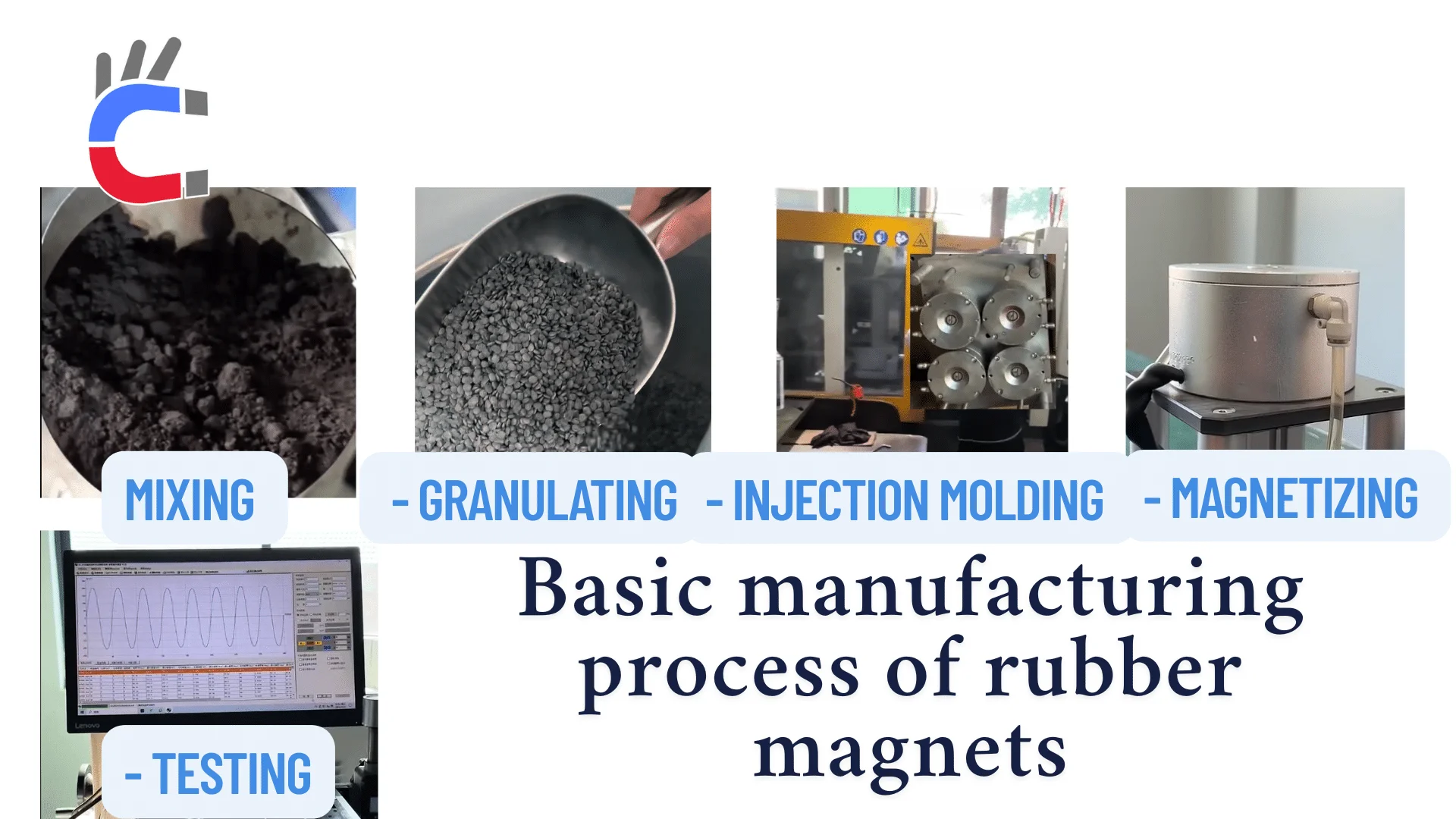

The Pursuit of Excellence: Production Process

The production of rubber magnets is a multi-step, sophisticated process aimed at ensuring the quality and performance of the final product.

Production Process for Rubber Magnets

- Raw Material Preparation and Surface Treatment

o Selection of Rubber Matrix and Magnetic Powder: Select appropriate rubber materials and magnetic powders based on product requirements.

o Surface Treatment of Magnetic Powder: This is a crucial step. Chemical treatments (e.g., coating a surface protectant), heat treatments, or acid washing are used to enhance the compatibility, adhesion, and uniform dispersion of the magnetic powder with the rubber while also preventing powder oxidation.

- Mixing and Forming

o Mixing Rubber and Magnetic Powder: The rubber matrix and the treated magnetic powder are mixed uniformly in precise proportions using an internal mixer or a twin-screw extruder to ensure the magnetic powder is fully dispersed in the rubber.

o Forming and Processing: The mixed material is formed according to the required product shape.

§ Compression Molding: Suitable for large-volume, simply shaped products.

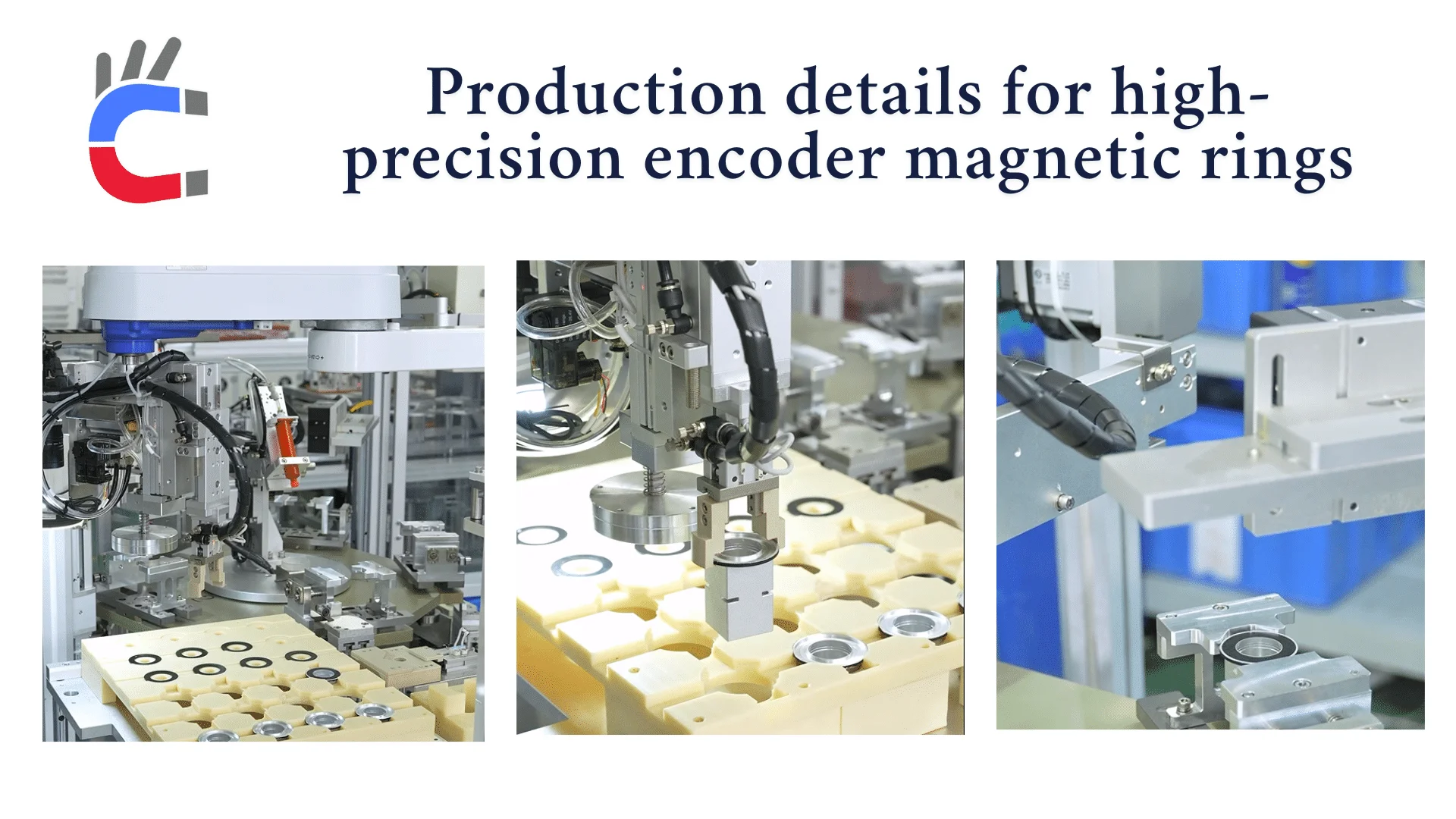

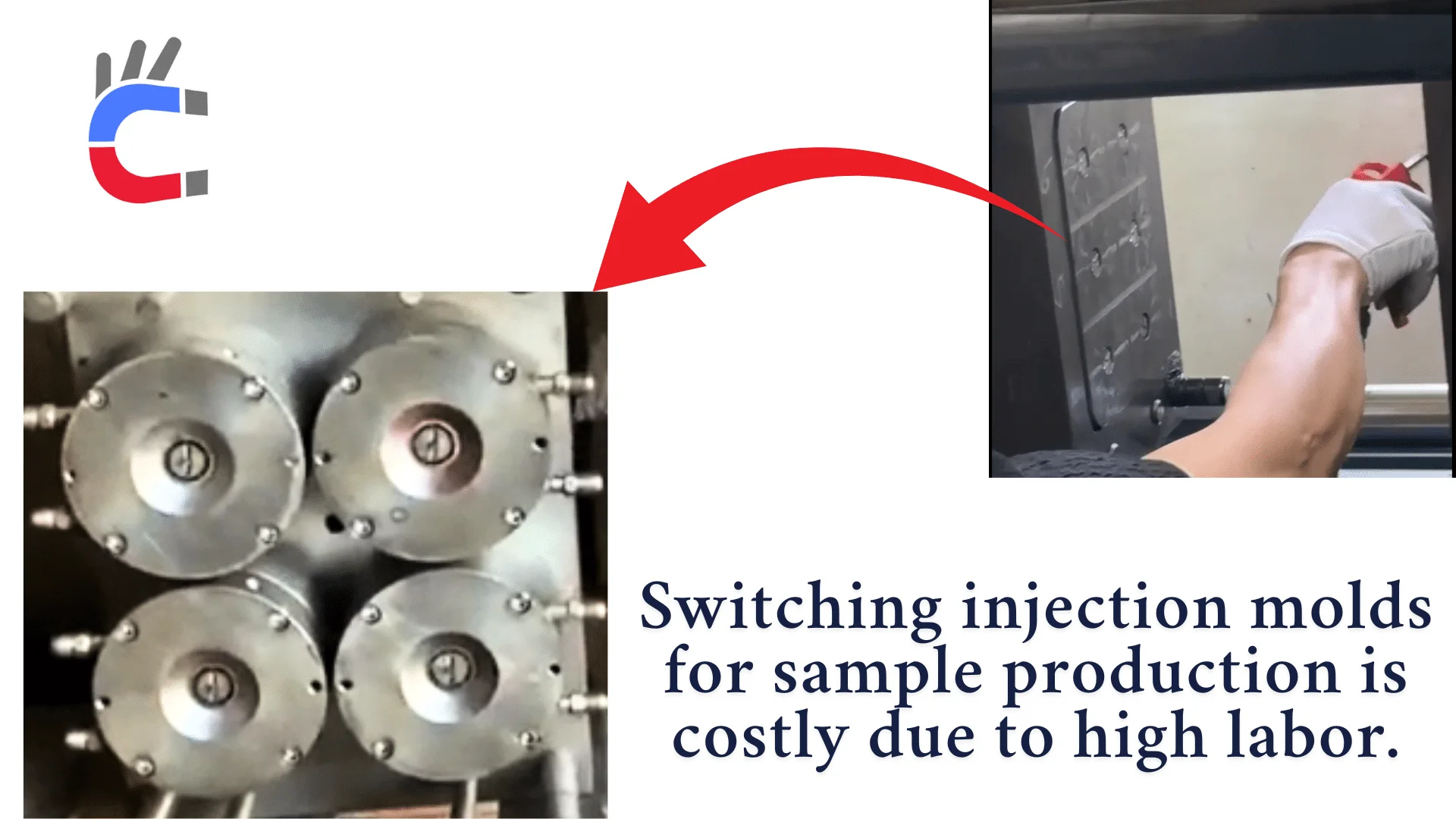

§ Injection Molding: Suitable for complex-shaped products, allowing for more precise control over size and shape, such as high-precision magnetic rings.

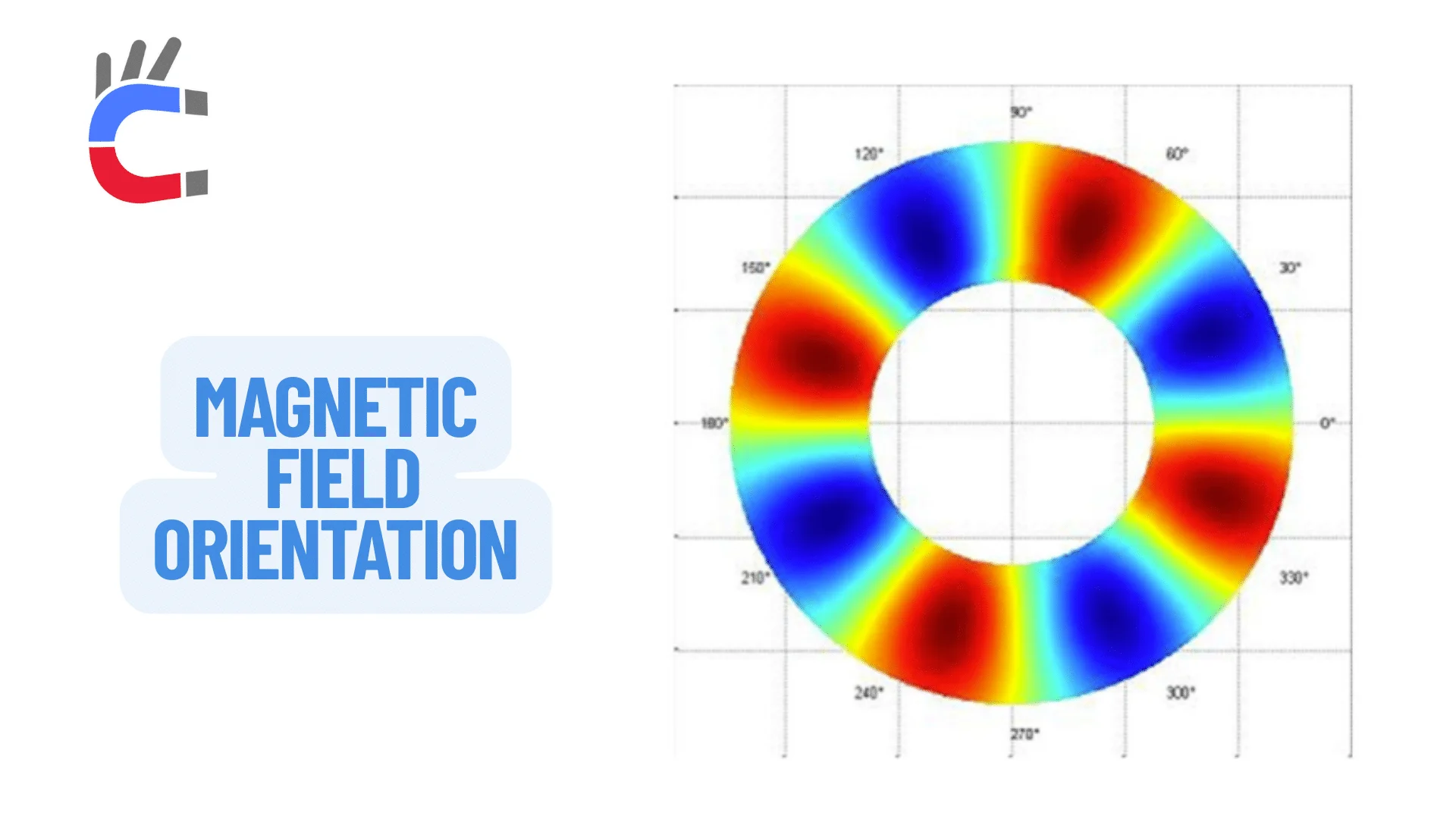

- Magnetic Orientation and Curing

o Magnetic Field Orientation Treatment: To maximize the magnetism of the rubber magnet, a strong magnetic field is applied while the mixture is heated to an appropriate temperature. This guides the alignment of the magnetic powder particles, causing them to be directionally arranged. This is a key step in imparting permanent magnetism to the rubber magnet.

o Curing: Through the curing process, a cross-linked structure is formed between the rubber molecules, giving the rubber material elasticity and strength. The magnetization step can be performed before or after curing, each with its own advantages and disadvantages. Magnetization before curing is more conducive to the magnetic field penetrating the rubber network, but magnetization after curing is more convenient to operate.

- Post-Processing and Quality Inspection

o Post-Processing and Trimming: The formed and oriented rubber magnet needs to undergo trimming, cutting, and grinding to ensure the product meets the expected dimensions and appearance.

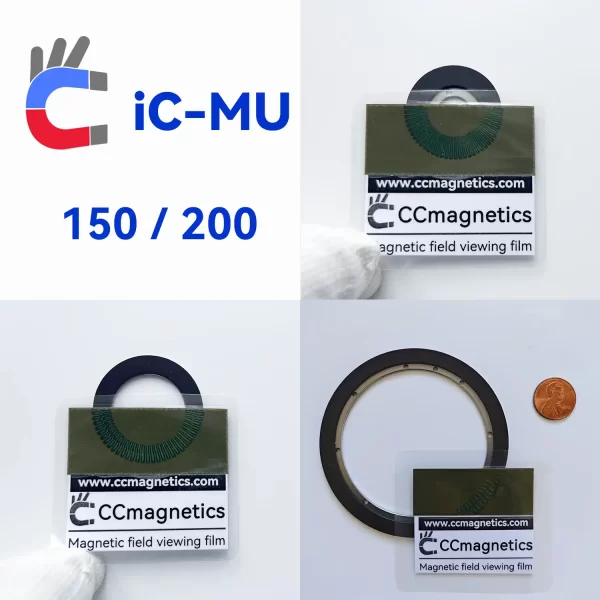

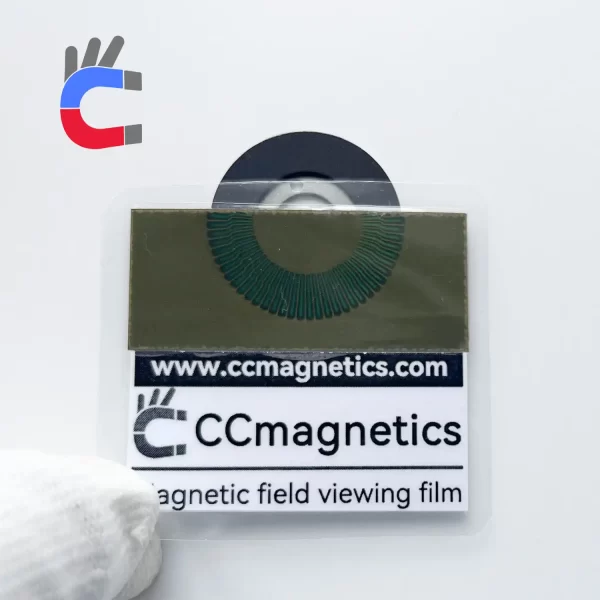

o Quality Inspection: The finished product undergoes comprehensive quality inspection, including dimensions, magnetic strength, angle accuracy (commonly measured in Gauss (Gs), typically requiring 100 to 600 Gs), appearance, and magnetic polarity, to ensure the product meets quality standards.

Magnetization Mechanism and Influencing Factors of Magnetic Rubber

Magnetization Mechanism

The magnetism of magnetic rubber originates from the magnetic powder within it. During the processing, these magnetic powders transform from non-anisotropic polycrystals into anisotropic single crystals. Under the action of a strong magnetic field, these non-oriented single particles align directionally within the rubber matrix, thus exhibiting magnetism in a specific direction.

Influencing Factors

- Magnetic Properties, Particle Size, and Content of Magnetic Powder: The higher the magnetic powder content, the stronger the magnetism of the rubber magnet. However, excessively high magnetic powder content may affect the physical and mechanical properties of the rubber. In general, smaller and more uniform magnetic powder particle sizes are more conducive to the dispersion of magnetic powder in the rubber, reducing the internal demagnetization phenomenon and improving the uniformity of magnetic properties. An ideal magnetic powder particle size is generally between 0.5**−3μm**.

- Type of Raw Rubber: Although the magnetism of magnetic rubber is generally independent of the type of rubber, different types of rubber affect its physical and mechanical properties and processing technology, thereby indirectly influencing the filling amount and dispersion effect of the magnetic powder.

Encoder magnets

Broad Application Fields

Due to its unique flexibility and ease of processing, rubber magnets show broad application prospects in many fields: industrial sensors, robotics, motion control, automotive, and medical fields. Specifically, they are suitable for rotary encoder switches (from medical devices to household appliances and even electric guitars), micromotors in dental drills, LiDAR applications, controlled small and micro actuators, absolute encoders, robot drives, servo drives, and linear actuators. With the continuous development of technology, the application fields of rubber magnets are still expanding. From the most common refrigerator magnets to high-end maglev technology, this incredible material is indispensable. In the future, rubber magnets are expected to play a unique role in more innovative fields.

Deutsch

Deutsch Русский

Русский Español

Español Français

Français 한국어

한국어 日本語

日本語