로터리 엔코더 마그네틱 링, 회전 앱솔루트 엔코더, iC-MU와 함께 사용하기위한 2 트랙 축 방향 자기 대상, 마그네틱 엔코더, 자기 다극 링, 유도 자기 링, 마그네틱 링 엔코더 자석, 센서 자석 중국 공급 업체, 다극 링 자석

불필요한 금형 비용 없음

전 세계 도어 투 도어 배송

출고 전 테스트로 정확성 보장

금형비 제로. 전 세계 배송. 전담 서비스. 필요한 제품을 찾고 그 과정을 즐기세요.

ccmagnetics는 방대한 금형 재고를 무료로 제공하여 고객의 시간과 비용을 절약해 드립니다. 고객의 니즈에 딱 맞는 완벽한 마그네틱 링을 찾도록 돕는 것이 저희의 약속입니다. 마그네틱 링 도면이나 사진은 영업팀에 문의해 주세요.

설명:

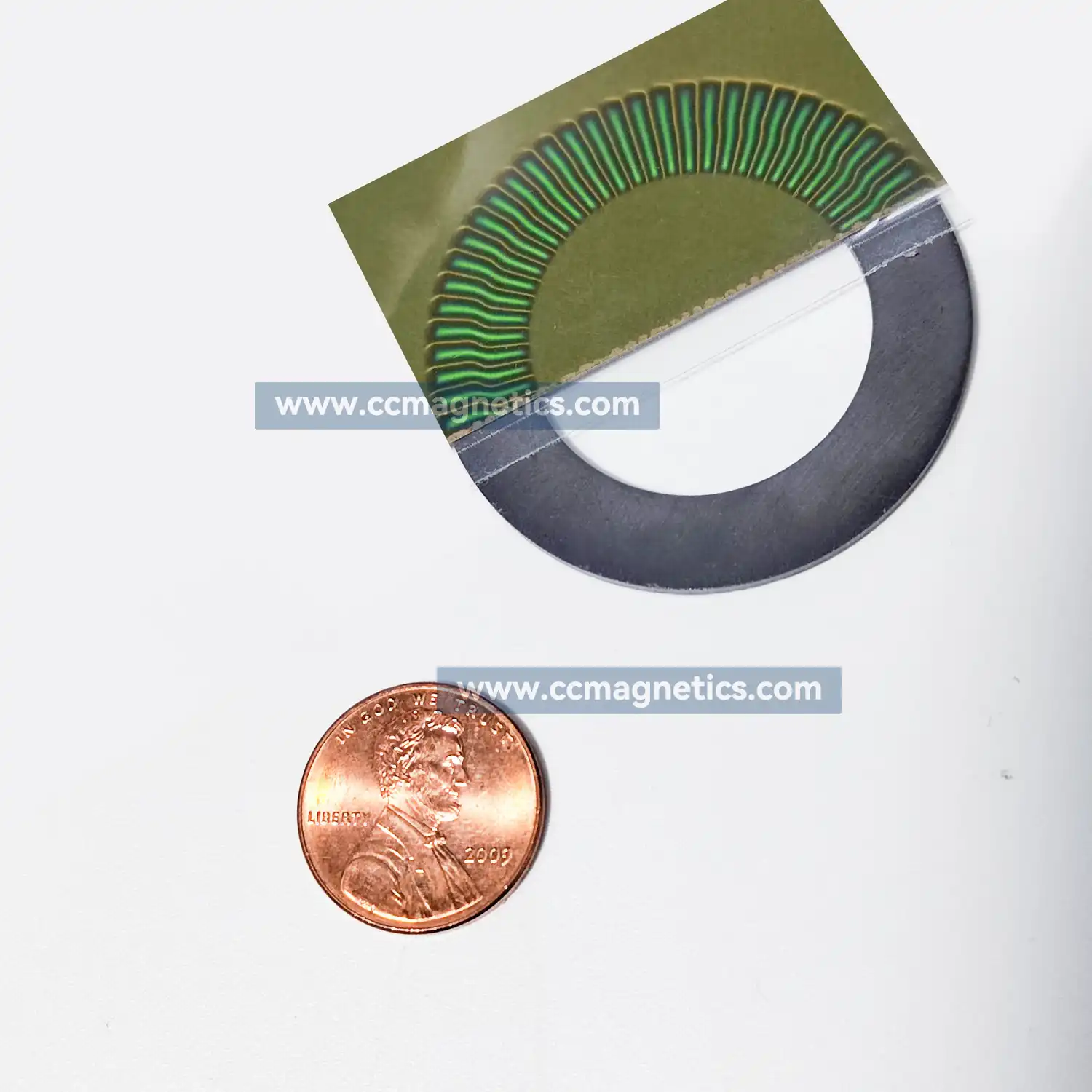

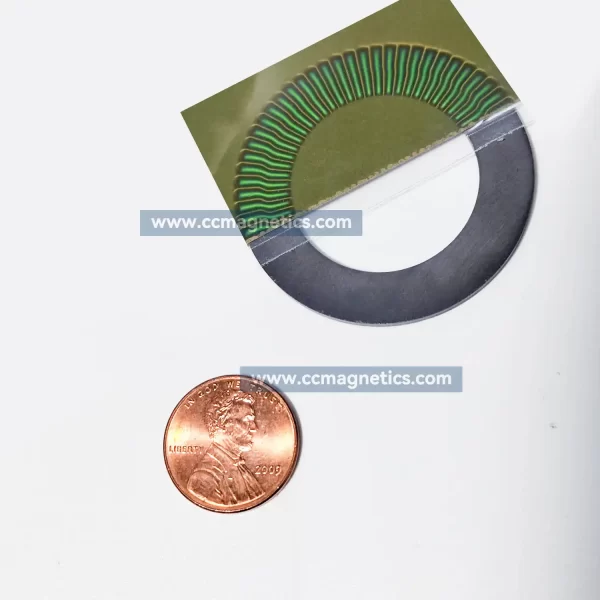

페라이트 인코더 마그네틱 링은 저렴한 비용과 높은 해상도 등의 이점을 제공합니다. 모든 마그네틱 링은 요구되는 정확도와 동심도 표준을 엄격하게 충족하며 축 방향 자화 방향이 일정합니다. 당사 제품은 다음과 같은 인증을 제공합니다:

- IATF16949(SGS에서 발급)

- ISO9001(SGS에서 발급)

- 관리 시스템 인증서(DNV에서 발급)

이 페이지에 나열된 페라이트 마그네틱 타겟은 IC-MU, IC-MU128 및 IC-MU150과 같은 센서와 호환됩니다. 저희의 경험을 바탕으로 한 다음 가이드라인을 참고하시기 바랍니다:

- 두께 1.4mm ~ 2mm: 독립적으로 사용할 수 있습니다. 필요에 따라 이 범위 내에서 두께를 선택하세요.

- 두께 1.4mm 미만: 페라이트 인코더 마그네틱 링은 올바른 작동을 위해 금속 캐리어가 필요합니다. 자세한 내용은 아래 다이어그램을 참조하세요.

| SKU | O.D (mm) | I.D (mm) | T (mm) | MT | NT | MATL | SF | MAG | CMTS |

|---|---|---|---|---|---|---|---|---|---|

| R0403 | 17 | 6 | 4 | 4 | 0 | Ferrite magnets | 180-190mT | Radial | |

| R0982 | 18 | 5.2 | 1.5 | 32 | 30 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm |

| R0988 | 23 | 12 | 2 | 74 | 3 | Ferrite magnets | 60-65mT | Axial | Pole pitch 0.8mm |

| R0986 | 26 | 13 | 2 | 30 | 10 | Ferrite magnets | 60-65mT | Axial | Pole pitch 2.46mm |

| R0622 | 26 | 13.2 | 2 | 30 | 10 | Ferrite magnets | 60-65mT | Axial | robot encoder ring |

| R0657 | 28.9 | 18.9 | 1.5 | 150 | 0 | Ferrite magnets | 60-65mT | Axial | robot encoder ring |

| R0987 | 29 | 15 | 1 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.28mm, compatible with ic-MU. |

| R0983 | 30 | 18 | 1.5 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.28mm, compatible with ic-MU. |

| R0688 | 32 | 24 | 1.5 | 44 | 0 | Ferrite magnets | 60-65mT | Axial | robot encoder ring |

| R0981 | 33 | 21 | 1.5 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150, Datasheet. |

| R0707 | 33.5 | 21.5 | 1 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0706 | 33.5 | 20.4 | 1.5 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0710 | 34 | 20.4 | 1.5 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Compatible with ic-MU150, Datasheet. |

| R0709 | 34 | 20.4 | 2 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0718 | 34.5 | 22.5 | 1 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0731 | 36.8 | 26.8 | 1.5 | 200 | 0 | Ferrite magnets | 60-65mT | Axial | |

| R0750 | 42 | 27 | 1.45 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 2mm, compatible with ic-MU200: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0749 | 42 | 28.5 | 1.45 | 128 | 0 | Ferrite magnets | 60-65mT | Axial | |

| R0756 | 44.2 | 34.7 | 1.5 | 48 | 0 | Ferrite magnets | 60-65mT | Axial | |

| R0979 | 44.5 | 29 | 1.4 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 2mm, compatible with ic-MU200, Datasheet. |

| R0768 | 45.2 | 30 | 1.5 | 48 | 0 | Ferrite magnets | 60-65mT | Axial | |

| R0980 | 45.7 | 35.8 | 1.5 | 128 | 0 | Bonded neodymium magnets | 80-95mT | Axial | The encoder magnetic ring has a pole pitch of 2mm and is available in two materials: ferrite and bonded neodymium magnets. |

| R0989 | 49 | 32 | 1 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 2mm, compatible with ic-MU200: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0777 | 49 | 32.8 | 1 | 64 | 62 | Ferrite magnets | 60-65mT | Axial | Pole pitch 2mm, compatible with ic-MU200: 32-pole pairs in master-track, 31-pole pairs in nonius-track. |

| R0957 | 51 | 35 | 10 | 80 | 0 | Ferrite magnets | 60-70mT | Radial | |

| R0804 | 55 | 42.5 | 1 | 128 | 126 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.28mm, compatible with ic-MU: 64-pole pairs in master-track, 63-pole pairs in nonius-track. |

| R0956 | 55 | 42 | 1.5 | 128 | 126 | Ferrite magnets | 60-70mT | Axial | Pole pitch 1.28mm, compatible with ic-MU, Datasheet. |

| R0810 | 56 | 41 | 2.4 | 128 | 126 | Injection molded ferrite magnets | 50-60mT | Axial | Pole pitch 1.28mm, compatible with ic-MU: 64-pole pairs in master-track, 63-pole pairs in nonius-track. |

| R0808 | 56 | 41 | 1.5 | 128 | 126 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.28mm, compatible with ic-MU, Datasheet. |

| R0809 | 56 | 41.5 | 1.5 | 128 | 126 | Ferrite magnets | 70-80mT | Axial | Pole pitch 1.28mm, compatible with ic-MU: 64-pole pairs in master-track, 63-pole pairs in nonius-track. |

| R0984 | 58 | 39 | 2.4 | 46 | 44 | Ferrite magnets | 60-65mT | Axial | Pole pitch 3.6mm |

| R0827 | 63.7 | 51 | 2 | 128 | 126 | Ferrite magnets | 80-90mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150: 64-pole pairs in master-track, 63-pole pairs in nonius-track. |

| R0830 | 64 | 53 | 2 | 128 | 126 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150, Datasheet. |

| R0985 | 65 | 51 | 2.4 | 128 | 126 | Injection molded ferrite magnets | 30-35mT | Axial | It's had pole pitch of 1.5mm and is available in two materials: ferrite and Injection molded ferrite magnets. compatible with ic-MU150. |

| R0751 | 65 | 51 | 2.4 | 128 | 126 | Ferrite magnets | 60-65mT | Axial | It's had pole pitch of 1.5mm and is available in two materials: ferrite and Injection molded ferrite magnets. |

| R0831 | 65 | 45 | 5 | 128 | 126 | Ferrite magnets | 60-65mT | Axial | Pole pitch 1.5mm, compatible with ic-MU150: 64-pole pairs in master-track, 63-pole pairs in nonius-track. |

| R0958 | 84.5 | 70.5 | 2 | 128 | 126 | Ferrite magnets | 60-70mT | Axial | Pole pitch 2mm, compatible with ic-MU200: 64-pole pairs in master-track, 63-pole pairs in nonius-track. |

용어집

| No. | 항목 | 설명 | 비고 |

|---|---|---|---|

| 1 | SKU | 재고 관리 코드 (SKU 번호) | 이 번호는 CCmagnetics에 문의를 제출할 때 기록하고 사용해야 합니다. |

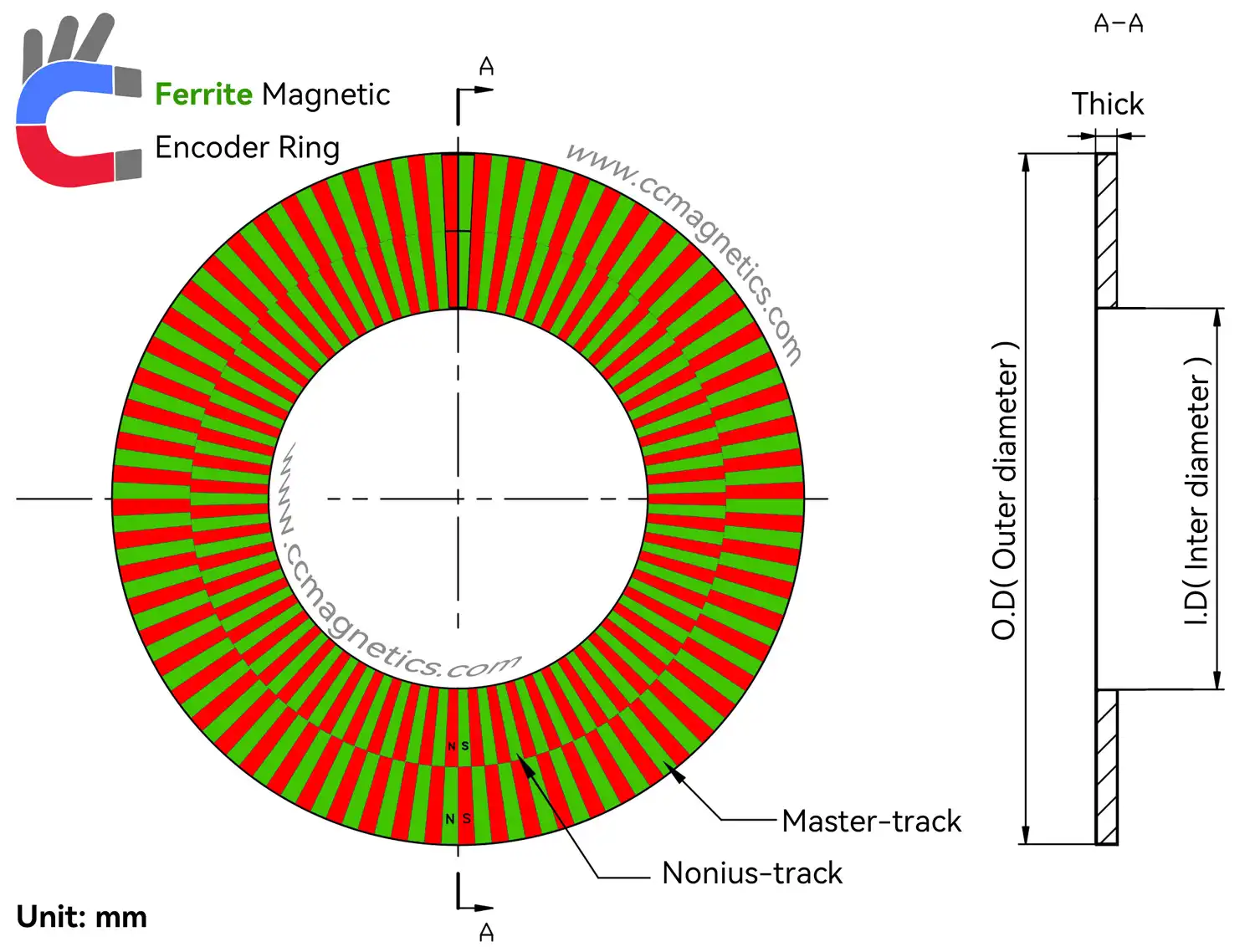

| 2, 3, 4 | O.D./I.D./T | 마그네틱 링 치수 | 표의 모든 치수는 밀리미터(mm) 단위입니다. O.D = 외경 I.D = 내경 T = 두께 |

| 5 | MT | 마스터 트랙 극수 | 단일 트랙이 있는 마그네틱 링의 경우, 마스터 트랙은 자극의 수를 나타냅니다. 예를 들어 "10극"은 5극쌍을 의미합니다. |

| 6 | NT | 노니우스 트랙: 극수가 더 적은 궤도 | 2트랙 마그네틱 엔코더 링의 경우, 노니우스 트랙은 일반적으로 더 적은 극수를 가집니다. 노니우스 트랙의 극수는 3극과 같이 홀수일 수도 있습니다. |

| 5 | MATL | 마그네틱 링 재질 | 마그네틱 링 재질에는 다양한 종류가 있습니다. 페이지 하단의 FAQ를 참조하십시오. |

| 6 | SF | 표면 자기장 | 이것은 표면 자기장의 세기를 나타냅니다. |

| 7 | MAG | 착자 방식 | 일반적인 착자 방식은 페이지 상단에 나열되어 있습니다. |

| 8 | CMTS | 코멘트 | 이 섹션에서는 마그네틱 링의 용도, 특징 및 기타 세부 정보에 대한 정보를 제공합니다. |

FAQ

Please send the SKU number and quantity of the magnetic rings you want from the list.

Your salesperson will send you a price quote and payment options (T/T 100% upfront or credit card 100% upfront).

- In-stock items: Ship immediately after payment.

- Out-of-stock items: Ship within 30 days after payment.

Our magnetic rings have a key benefit: transparent costs for molds and magnetizing coils. We don't charge extra for these.

For small sample orders (around 10 pieces), this stock is usually leftover from larger production runs. Please pay quickly to secure your stock. We don't start production for small orders; it's not cost-effective for us.

We usually start production for orders over 2k-10k pieces to manage costs. If your order is small and not confirmed quickly, you might miss out on current stock.

Sizes: All lengths are in millimeters (mm) by default.

Number of poles:

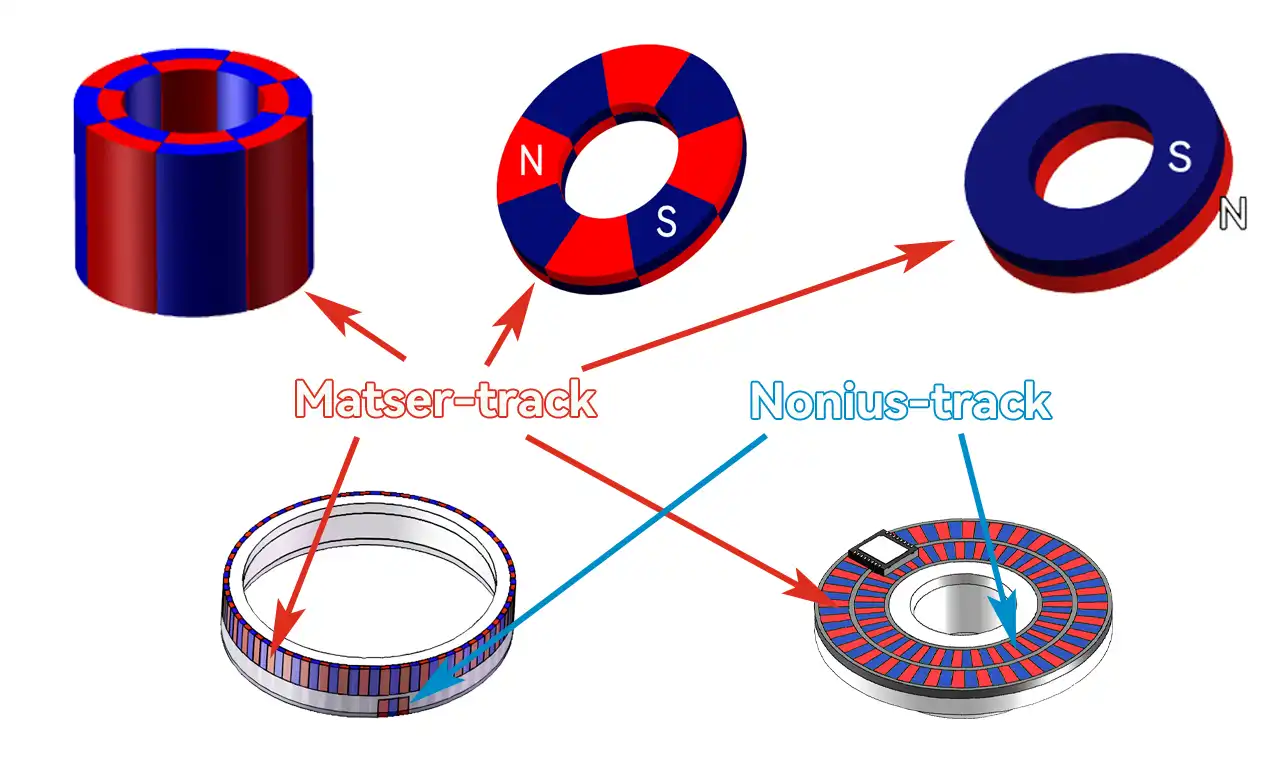

- The Master-track refers to the main magnetic track's pole count on a ring magnet. Most ring magnets, like those for motors or incremental encoders, have only one magnetic track.

- However, absolute encoder ring magnets or encoder ring magnets with marker points also have a Nonius-track. This means they have two magnetic tracks, as shown in the picture.

- Ferrite magnets are also called sintered ferrite or hard ferrite magnets. They look and are made like ceramics, so some call them ceramic magnets.These magnets are cheap to make in large amounts, even though the mold costs are high. They are very good at resisting rust and high temperatures, up to 250℃.Ferrite magnets are accurate and low-cost for encoders. But, they can break easily if shaken a lot, like in outdoor robots. For those, Vulcanized rubber magnet material is more stable.

- Injection molded ferrite magnets are made by mixing ferrite magnetic powder with plastic binders like Nylon (PA6 or 12) or PPS. This mixture is then injection molded, meaning it's shaped using a mold.These magnets can even be molded directly onto a metal shaft. They can work in temperatures up to 150°C.

Bonded neodymium magnets are made by mixing neodymium magnetic powder with a binder.

Simply put, they are injection molded, which means they contain a binder. About 80% of the magnet is neodymium powder, and the remaining 20% is binder.

Their benefits include high dimensional accuracy, great design flexibility, and good mechanical strength.

Injection molded neodymium magnets are made by mixing neodymium magnetic powder with thermoplastic. This mix is then injection molded. These magnets are stronger than injection molded ferrite magnets.

Injection molded neodymium magnets can be made into many shapes. They can be small or irregular. You can magnetize them with multiple poles or complex patterns. They are also very accurate and consistent in shape.

These magnets can be molded directly onto motor cores or metal shafts. This saves assembly costs. They are seen as a stronger option than injection molded ferrite magnets. They can work in temperatures up to 180℃.

These magnets are injection molded neodymium or ferrite magnets that include a metal carrier. Please see the picture below:

These magnets are injection molded neodymium or ferrite magnets that include a metal carrier. Please see the picture below:

Sintered NdFeB magnets are also called Sintered Neodymium magnets. These are the strongest known permanent magnets. They are made from neodymium (Nd), iron (Fe), boron (B), and other rare earth elements.

These magnets create very strong magnetic fields and stay magnetic at room temperature. They can be made into many shapes. This makes them great for many uses, especially for high-end commercial motors.

Sintering is how they are made. Powdered materials are heated until they merge. This process makes the magnets stronger and more effective.

However, these magnets can corrode easily and are affected by high temperatures. So, they are usually coated (often with a nickel-copper-nickel layer) to protect them. Adding heavy rare earth elements also helps them resist higher temperatures.

- Vulcanized rubber magnet material is made when magnetic powder is added to rubber during a process called vulcanization. This process changes the rubber's structure, making it much stronger, more elastic, and more stable.Vulcanized rubber magnets are often used for magnetic targets on sports robots. They are flexible and don't break easily from shocks.

- Rubber magnets are made from magnetic powder mixed with synthetic rubber. They are formed by extrusion, calendering, or injection molding. You can make them into strips, rolls, sheets, blocks, rings, and many other shapes. Their main advantages are that they are flexible and can be made into various shapes.However, their disadvantage is that they are not very strong (they don't have high remanence) compared to Neodymium magnets. For encoders, regular rubber magnets can't meet high precision needs. They are only good for single-track incremental encoders.

English

English Deutsch

Deutsch Русский

Русский Español

Español Français

Français 日本語

日本語

상품평

아직 상품평이 없습니다.